Food and beverage manufacturers have made great strides during the past couple of decades when it comes to sustainability, and dairy processors are no exception. In fact, many — if not most — dairy processors have set ambitious sustainability goals and are working hard to attain them.

Ongoing efforts within the dairy processing space are multi-faceted. A single dairy processor’s sustainability program likely has enough components to warrant its own feature article.

With that reality in mind, Dairy Foods opted to home in on some recent processor projects that are part of each company’s bigger sustainability picture. Read on for a little sustainability inspiration.

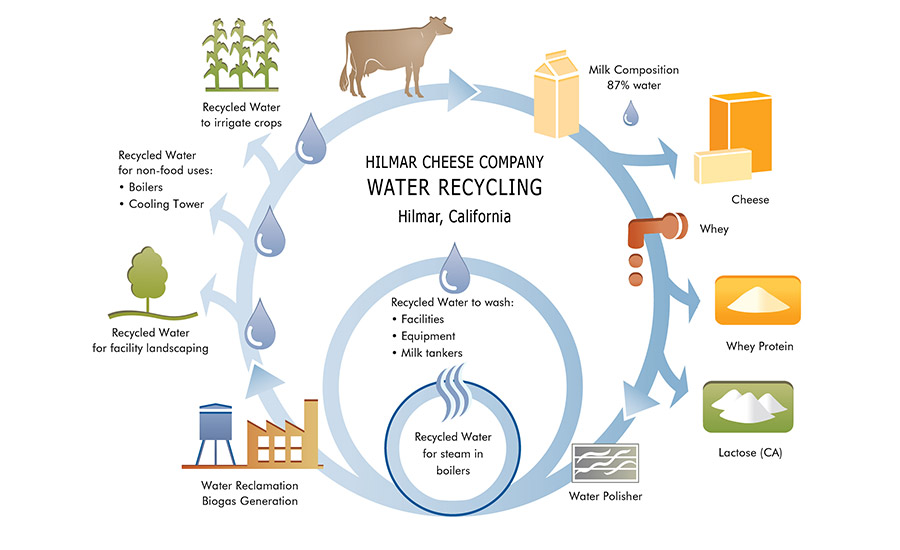

A new process, depicted in the dark blue outline, allows Hilmar Cheese Company to reuse 250,000 gallons of water daily for select boilers.

A new process, depicted in the dark blue outline, allows Hilmar Cheese Company to reuse 250,000 gallons of water daily for select boilers.Water stewards

As part of its sustainability push, Hilmar Cheese Company Inc. actively looks for ways it can reduce, recycle, reuse and conserve water, explains Michael Wood, director of environmental, safety, health and security for the Hilmar, Calif.-based company. A recent project allows the company to use a significant amount of recycled water in boilers.

“Both manufacturing sites have complex multistage water reclamation systems consisting of several steps, including equalization, anaerobic and aerobic digestion and storage,” he says. “In 2019 and 2020, the company worked through state and local regulation to be able to use recycled water in several manufacturing boilers.”

Wood says the new process, depicted in the dark blue outline in the above Hilmar Cheese diagram, allows the reuse of 250,000 gallons of water daily for the boilers. The company evaluated the results based on water reuse and minimization of groundwater use.

“The change required data, information, validation and a proposal to various regulatory agencies,” he says. “The conversations are ongoing to look at ways we can further reuse water and enhance the process. … This project represents another step toward our sustainable future.”

Water conservation was also the focus of a recent Michigan Milk Producers Association (MMPA) project. Earlier this year, Novi, Mich.-based MMPA completed the installation of a new influent tank at its Ovid, Mich., plant’s wastewater treatment plant.

According to Gasper Calandrino, MMPA’s director of engineering, the cooperative added the new tank to provide redundancy so the original tank could undergo maintenance services. But MMPA reaped benefits that go beyond redundancy.

“The new tank also provides additional buffering and dilution of daily loads from the main processing plant,” he points out. “A further benefit was the addition of an online COD [chemical oxygen demand] measurement system to provide high-strength capture and alarming should an unusually strong loading spike occur.”

Before installation, MMPA completed a thorough analysis of impacts to the wastewater treatment process at the Ovid facility, Calandrino explains.

“Through this analysis, we developed a control process to determine the best benefits from adding the tank to the system,” he says. “This analysis focused on impediments to consistent phosphorus removal, causes of permit exceedances and critical failure scenarios.”

To address the impediments, MMPA added “several modes of operational flexibility” to the tank control system, he says. They allow for tank isolations (each tank), high-strength capture and lead/lag operation. “The control system allows for continuous real-time trending of incoming loads,” he notes. “These trends will be used to continually improve the effectiveness of the high-strength capture system.”

The new influent tank has been a major positive in MMPA’s wastewater treatment efforts. The cooperative’s lab measurements and analyses, Calandrino says, have indicated increased stability, as well as greater treatment effectiveness. And the treated effluent has been in compliance since the tank’s commissioning. The project is just one example of MMPA’s sustainability commitment.

“At MMPA, we are mindful that our business decisions and operations have a direct impact on our environment, communities, customers and coworkers,” Calandrino says. “We believe social responsibility and sustainability [are] not just a destination, but a journey toward continuous improvement.”

Earlier this year, Novi, Mich.-based MMPA completed the installation of a new influent tank at its Ovid, Mich., plant’s wastewater treatment plant.

Earlier this year, Novi, Mich.-based MMPA completed the installation of a new influent tank at its Ovid, Mich., plant’s wastewater treatment plant.

A ‘greener’ ingredient

Earlier this year, NZMP, a dairy ingredient and solutions brand of the New Zealand-based Fonterra Group, launched a carbonzero certified organic butter to the North American market. The brand said the new ingredient will help its customers achieve their own sustainability goals and capitalize on consumer demand for more sustainable products.

“With 72% of global consumers expressing an interest in brands that actively communicate achievements around sustainability, the introduction of carbonzero ingredients is just one way in which NZMP customers can leverage Fonterra’s sustainability solutions,” says Megan Patterson, Americas marketing manager, NZMP/Fonterra Sports & Active Lifestyles.

She notes that NZMP also wanted to make a product to help promote its “environmental values while growing brand preference and market share through differentiated products.” In New Zealand, Fonterra already boasts one of the world’s lowest on-farm carbon footprints, putting the NZMP brand “in a strong position to offer sustainability solutions that help customers reduce their environmental impact, while claiming an advantage in the market.”

NZMP’s first certified carbonzero ingredient was audited and verified by a New Zealand-based independent certifier, Toitū Envirocare, Patterson notes. Toitū audited and verified the carbon emissions for the butter across the supply chain. NZMP also had to demonstrate how it has reduced its emissions to date, as well as reveal its plans for further reducing its emissions.

“The final step in the certification is offsetting the verified carbon footprint with high-quality carbon credits approved by Toitū — which can be anything from native forest regeneration or renewable energy projects,” Patterson explains.

NZMP’s first carbonzero certified ingredient was audited and verified by a New Zealand-based independent certifier, Toitū Envirocare.

NZMP’s first carbonzero certified ingredient was audited and verified by a New Zealand-based independent certifier, Toitū Envirocare.

Looking up

The Kraft Heinz Co. aimed high — literally — with a recent sustainability venture. In late 2020, the Pittsburgh- and Chicago-based company completed a pilot project that involved the installation of roofing material made from post-consumer flexible plastic on the roofs of two of its plants — a dairy processing facility in Beaver Dam, Wis., and a nondairy plant in Holland, Mich. According to Kraft Heinz, the roofing materials comprise 4-foot-by-8-foot boards; 94% of each board consist of post-consumer recycled plastic and fiber content.

The pilot project was made possible by the company’s participation in Materials Recovery for the Future (MRFF). MRFF is a nonprofit research collaborative that set out to prove the technical and economic feasibility of collecting, sorting, baling and recycling flexible packaging, Kraft Heinz says.

The company notes that it will be monitoring the roofing for performance versus roofing with standard building materials. If the recycled materials perform as well as or better than standard building materials, Kraft Heinz will “strongly consider” standardizing the use of such materials in the future. The company also says it will report on its use of recycled content to the Association of Plastic Recyclers’ Demand Champion program, which it joined in 2020.

“It was a privilege being part of MRFF, which not only helped identify ways to curbside collect and recycle flexible packaging, but also identified end markets that we could leverage within our facilities,” says Erik Groner, senior principal packaging engineer for Kraft Heinz. “Our test project highlights the company’s commitment to sustainable packaging and the priority it places on its environmental, social and governance commitments.”

In late 2020, Kraft Heinz completed the installation of roofing material made from post-consumer flexible plastic on the roofs of two of its plants — a dairy processing facility in Beaver Dam, Wis., and a nondairy plant in Holland, Mich. (pictured).

In late 2020, Kraft Heinz completed the installation of roofing material made from post-consumer flexible plastic on the roofs of two of its plants — a dairy processing facility in Beaver Dam, Wis., and a nondairy plant in Holland, Mich. (pictured).

Champion of renewable energy

Organic Valley has big bragging rights: The La Farge, Wis.-based cooperative is now the largest food brand to source all of its electricity for its own facilities from 100% renewable energy. That achievement was realized via “332 rooftop solar panels that generate 200 kilowatts, geothermal heating and cooling, a Cashton Greens wind farm and vertical warehouse storage for more efficient cooling,” explains Elizabeth McMullen, public relations specialist for CROPP cooperative /Organic Valley. Reaching that milestone was not easy, however.

“Two creative and bold energy companies, OneEnergy Renewables and a group of Midwestern municipal utilities referred to as the Upper Midwest Municipal Energy Group (UMMEG), worked day and night to figure out how to structure the project,” she explains. “They, along with the city of Madison, Dr. Bronner’s and Clif Bar, brought their own intrepid goals to the table. Advocates and scientists at Fresh Energy, the National Renewables Energy Lab and the Bee and Butterfly Habitat Fund were engaged to find even more opportunities to create environmental benefits.”

The plans expanded well beyond corporate headquarters — and the logistics expanded right along with them, McMullen notes.

“Between the 10 arrays in the full project, the team expected to increase the solar energy produced in Wisconsin by 30%, she says. “It was a big goal, and with solar tariffs and the elimination of government tax credits on the horizon, there were no options but to either run full steam at the goal or stop the projects in their tracks.”

The cooperative opted to run full steam at the goal.

“In January 2019, some of the hardiest and hard-working people on Earth forged ahead into a brutal winter,” McMullen says. “They installed hundreds of steel posts and panel supports in frozen ground.”

The following spring, the same people battled muddy conditions to begin installation of the panels, wiring and other equipment required to finish the project. By Aug. 1, 2019, all of the solar panels were finally in place.

“Organic Valley was the catalyst and lead partner in the development of a 32-megawatt, utility-scale solar project that directly benefits 10 communities and more than 23,000 rural households in the Upper Midwest,” McMullen says.

Organic Valley is now the largest food brand to source all of its electricity for its own facilities from 100% renewable energy.

Organic Valley is now the largest food brand to source all of its electricity for its own facilities from 100% renewable energy.

A socially responsible launch

Sustainability encompasses more than environmentally focused efforts. Social and economic elements also are key sustainability pillars.

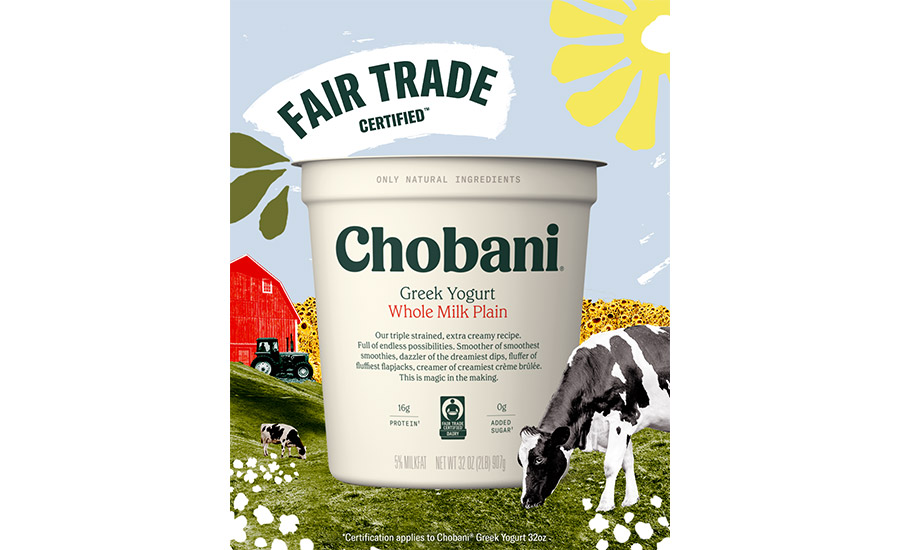

Norwich, N.Y.-based Chobani LLC demonstrated its commitment to all three pillars with the 2021 launch of the first-ever Fair Trade Certified retail dairy items. The launch encompasses all of the company’s 32-ounce multi-serve Greek yogurt tubs, including whole milk Plain, low-fat Plain, non-fat Plain, Strawberry Blended and Vanilla Blended varieties, explains Peter McGuinness, Chobani’s president and chief operating officer.

“Fair Trade USA’s groundbreaking certification program for U.S. dairy farms and cooperatives provides financial premiums to dairy farmers and workers, which will help protect and empower them while raising sustainability standards,” he says. “Fair Trade USA has certified products ranging from jeans to coffee, but never dairy. As dairy experts, Chobani played a critical role in developing and implementing the program with Fair Trade USA in order to strengthen the economic, environmental and social standards throughout the company’s milk supply chain.”

Chobani first worked with Fair Trade USA and dairy cooperatives Dairy Farmers of America and Cayuga to “educate, develop, recruit, assess and certify” eight dairy farms for the pilot program, McGuinness says. Each of the farms underwent a rigorous assessment and then was required to resolve noncompliant aspects tied to operations prior to certification.

“Simultaneously, Fair Trade USA conducted a revision of their Agricultural Production Standard, which is currently implemented across 250-plus commodities in more than 40 countries, to ensure its applicability to the dairy context,” he adds. “This standard was created for crop production in the Global South, but after engaging with various dairy stakeholders — including farms, cooperatives, brands, retailers, academics, other labor organizations, etc. — they were able to use its foundation to create a dairy amended version to address the unique challenges in dairy.”

McGuinness says the dairy farm certification process typically requires six to nine months. In addition, farms will be required to undergo annual audits to verify compliance with the Fair Trade Standard.

When they purchase Fair Trade Certified milk, milk buyers pay the Fair Trade Premium, and that premium is allocated to a community development fund, he explains.

“The premiums paid to the farms will address two funds,” McGuinness says. “A third of the premium goes toward compliance support, ensuring farmers have the resources they need to implement improvements, including advanced training programs, updating personal protective gear and first aid certification. The other two-thirds of the premium can support insurance subsidies, language learning, scholarships or any other need felt by the community — but importantly, farmers and workers get to decide how those funds are spent, depending on their greatest needs.”

Chobani LLC demonstrated its commitment to all three pillars of sustainability with the 2021 launch of the first-ever Fair Trade Certified retail dairy items.

Chobani LLC demonstrated its commitment to all three pillars of sustainability with the 2021 launch of the first-ever Fair Trade Certified retail dairy items.

Focused on fuel savings

Fuel consumption is one of the many sustainability focus areas for Akron, N.Y.-based Perry’s Ice Cream Company Inc. Since 2010, the company has improved its miles-per-gallon performance across company vehicles by an impressive 36% (the company operates its own fleet of vehicles for direct store delivery), according to Gayle Perry Denning, vice president of corporate sustainability and branding.

Moreover, this year, Perry’s earned entry into the U.S. Environmental Protection Agency’s SmartWay program, which focuses on improving the freight transportation sector of supply chain efficiency. The program aims to reduce emissions tied to climate change and boost global energy security, she notes, while helping freight partners enhance efficiencies by measuring, benchmarking and streamlining their freight-related operations.

“More than 3,700 companies and organizations currently participate in the program,” Perry Denning says. “And over the past several years, Perry’s transportation teams have worked together to increase fuel efficiencies through investment in new equipment, driver training and metrics benchmarking. This earned their SmartWay designation, as well as admiration from the initiative.”

That means Perry’s will contribute to the partnership’s estimated savings of 312 million barrels of oil, $41.8 billion in fuel costs,133 metric tons of CO2, 2.6 million tons of NOx and 109 million tons of particulate matter.

“This is equivalent to eliminating annual energy use in over 20 million homes,” Perry Denning notes. “By joining SmartWay Transport Partnership, Perry’s demonstrates its strong environmental leadership and corporate responsibility.”

Since 2010, Perry’s Ice Cream Company has improved its miles-per-gallon performance across company vehicles by an impressive 36%.

Since 2010, Perry’s Ice Cream Company has improved its miles-per-gallon performance across company vehicles by an impressive 36%.

‘Setting the record straight’

In recent years, a number of groups and individuals have accused the dairy industry — on the farm side, in particular — of being environmentally irresponsible. That is far from the case. And Dairy Farmers of America (DFA) launched a new campaign to “set the record straight,” says Kristen Coady, senior vice president of corporate affairs for the Kansas City, Kan.-based cooperative.

Launched on June 1 — World Milk Day — the month-long “Nerd Herd” campaign was designed to educate consumers about the cooperative’s sustainability initiatives, as well as tell the real story about dairy’s environmental impact.

“Led by farmers and a team of engineers, nutritionists, veterinarians, technology experts, scientists and more, the DFA Nerd Herd is working to make dairy production even more sustainable with farms powered by sun and wind energy, soil health practices and cows’ waste turned into electricity,” Coady explains.

In the “humorous, yet informative” videos, a DFA Nerd Herd member frees various dairy products from environmental misconceptions by pointing to a number of initiatives in place for reaching zero emissions by 2050, she adds. In addition to the videos (on YouTube, Hulu and other digital platforms), the campaign also included newspaper ads in The Washington Post, Politico and select local markets introducing the Nerd Herd; a Buzzfeed quiz separating myths from facts when it comes to dairy’s environmental impact; out-of-home advertising in key markets; and a “robust” social media campaign.

After National Dairy Month in June, DFA has plans to release additional videos through 2021 that highlight the cooperative’s sustainability efforts, Coady says.

“For our farm families, sustainability is a way of life and a responsibility for future generations, but unfortunately, there are a lot of falsehoods and misinformation out there today about dairy’s impact on the environment,” she adds. “Through the Nerd Herd and this media campaign, we want to correct that misinformation and help educate consumers on how we, along with our farm family-owners and Nerd Herd members that support them, are doing our part to produce dairy responsibly, ethically and sustainably. We hope the key takeaway is that consumers can and should feel good about enjoying their favorite sustainably made dairy products.”

DFA’s month-long “Nerd Herd” campaign was designed to educate consumers about the cooperative’s sustainability initiatives, as well as tell the real story about dairy’s environmental impact.

.jpg?height=200&t=1630591584&width=200)