Summary

This article addresses cheese plant owners, operation general manager, projects engineers or however is interested in purchasing state-of-the-art 2024 exact weight cheese cutting technology, for chunk and stick cutting (8oz to 4lbs cheese loaf). Here we are presenting a simplified model to rapidly evaluate the yearly saving resulting from the investment in state of the art cheese cutting technology. We shall look at how new technologies can provide savings in the following area:

- Cheese losses reduction

- Cheese Trim reduction

- Product Give-Away reduction

- Labour savings

Establishing a value on cheese cost and trim penalty

Cheese Cost:

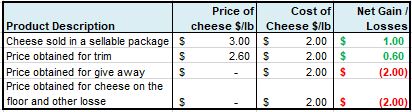

When cheese ends up on the floor or as overweight in packages these can be considered as net losses it is the equivalent as throwing cheese out the window. For the purpose of this exercise, we will set the value of cheese at $2 per pound, which is equivalent to the cost of manufacturing it.

Cheese-cutting equipment from COPRODEV and conveyors are equipped with catch pans throughout their entire lengths to recuperate cheese crumbs.

Cheese Trim:

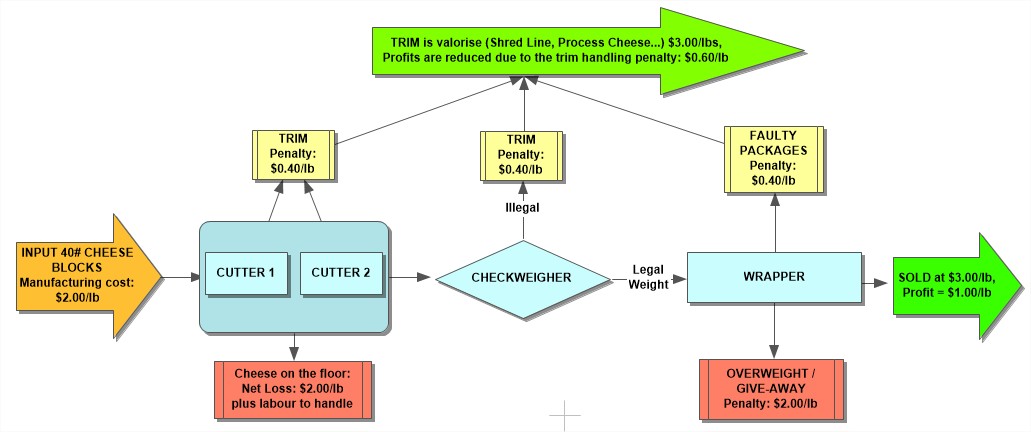

Trim is usually generated from two sources:

-

Trim generated by the cheese cutters because of dimensional irregularities of the native cheese blocks and lacking adjustment flexibility from old school harp cutting technology. These “fixed size” technologies will generate as much as 12% trim whereas newer technologies which can “adapt” to changing cheese bar length will reduce trim by 50%

-

When illegal weights are rejected at the checkweigher this also generates trims, manually adjusted cutters will perform at 85 to 90% accept rate at the scale where as COPRODEV PLUS MACH-III ultrasonic equipped with 3D vision will exceed 98% accept rate at the scale

Cheese Trim is not a net loss because the cheese is recuperated and re-valorised into process cheese or shred lines. However there is a significant penalty when producing trim due to the labour associated with the handling cost of it. We will set the penalty of making trim at 40 cents per pound

When was the last time that you have measured and documented your cheese losses and trim percentage?

Focus on product give-away

When cutting cheese to exact weight two simple rules (federal laws) must be followed:

- The average weight of the production lot must be equal or greater than the declared weight.

- Legal underweight are authorized up to a legal limit; the MAV (Maximum Authorised Variation) et by the U.S. Department of Commerce.

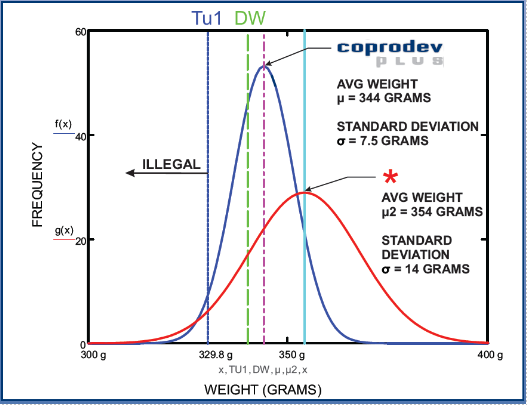

When looking at a cheese cutter performance one should look at the average weight observed at the checkweigher annunciation HMI and the standard deviation shown. In my opinion the standard deviation is the most important statistical parameters to consider, it is a measure of dispersion the smaller the number the better it is. A low standard deviation will allow the operator to lower its target weight without penalizing the accept rate. The following slide illustrates this phenomenon for a declared weight of 12oz or 340 grams:

COPRODEV PLUS PERFORMANCE: Avg Weight: 344 g (4g give-away), 7.5g S.D.

OTHER TECHNOLOGY: Avg. Weight: 354g (14g give-away), 14.0 g S.D.

Putting it all together

If cheese is sold at $3/lb and the manufacturing cost is $2/lb, the theoretical maximum profit that can be generated is $1/lb. However, this profit will be degraded because of trim generated at the cutters, illegal weight rejected, and product given- away due to in-accurate cheese cutter.

Labor saving

Labor saving is a straight and easy calculation taking into account the net throughput at the wrapper, the line OEE (Overall Equipment Efficiencies) the number of operator per line-hour, and the cost of personnel including fringe benefits. See our case study below. COPRODEV PLUS technology is fully automatic, other than the personnel required to load the 640/40lbs cheese blocks on the accumulation conveyor simple supervision is required – one operator part-time.

Detailed computation of savings based on 1 million LBS

Premises (Cost of Cheese VS Trim Penalty)

Cheese Savings

LABOUR SAVINGS PER 1 million LBS

In summary for one million lbs of cheese reduced to 12oz portions (from 40lbs or 640lbs blocks) COPRODEV technology has the potential to save $24,700.00 ie $138,000.00 in cheese savings and $106,700.00 in labor.

The provided tools in this article should be considered as a first step to rapidly evaluate the feasibility of an investment in new cheese technology. More advanced method such as 10 years cost of ownership, Accountant’s ROI or Net Present Value of cash outlays would provide a more complete assessment.

*** Contact jdbedard@coprodev.com to obtain Excel templates for the above tables.

Conclusion

As a developer of cheese-cutting technology, I keep telling my engineers and equipment designers that cheese is like gold. It is a very expensive product; it takes 10 lbs of milk to produce 1 lb of cheese. Small improvements in cheese losses, trim, or giveaway will translate rapidly into large sums of money. For those high-volume plants operating three shifts / 5 days a week, potential savings are colossal. I would scrutinize every aspect of my cutting line if I were the owner.

Don’t miss our next bulletin focusing on the check weigher, the “pièce de résistance” regarding weight control strategy.

Do not hesitate to send me your comments.

jDenis Bedard, jdbedard@coprodev.com

Copyright 2024, jD Bedard – COPRODEV PLUS INC.