From a small 5,000-square-foot plant in Springfield, Ill., solely focused on making ice cream mixes, to a large, 126,000-square-foot plant in Dubuque, Iowa, that processes nearly 40 million pounds of fluid milk a month, to the team at the Faribault, Minn., plant who earned the top prize for their handcrafted Cave Aged Rinded Swiss, Prairie Farms Dairy boasts a wide range of manufacturing operations.

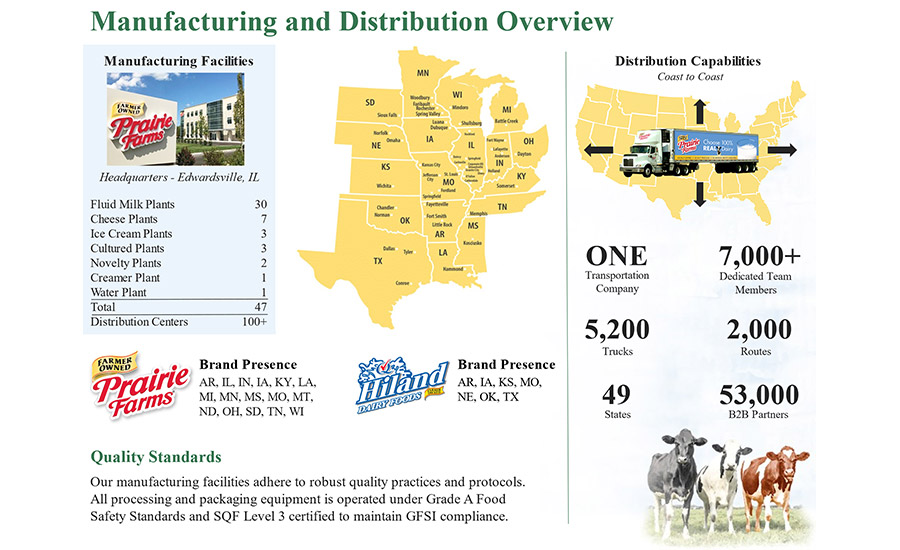

Founded in 1938, Prairie Farms Dairy is a large cooperative headquartered in Edwardsville, Ill., which is located about 25 miles northeast of St. Louis. Since August 2017, more than 100 employees have called the 30,000-square-foot facility home. Additionally, the company says that 7,000-plus dedicated employees contribute to the production and delivery of a plethora of dairy products made at 47 manufacturing plants in 18 states.

Regardless of the products being produced, it all starts with high-quality milk. Prairie Farms relies on the freshest dairy milk from more than 600 multigenerational, independent family farms to manufacture thousands of dairy products for its $4.6 billion business. Products include white and flavored milk, premium ice cream, frozen novelties, ice cream mixes, cheese, whipping cream, half & half, cottage cheese, yogurt, sour cream, and dips.

"Prairie Farms is a unique company because we're a co-op, and earnings go back to our dairy farmers," notes Chris Hackman, Prairie Farms chief operating officer. "Our operations, quite simply, start at the farm and end at the table. We work hard to make sure the milk is processed within 24 to 48 hours of being picked up from our farms.

"We have small and medium farms primarily in the upper Midwest that produce the highest-quality milk. We handle the packaging and distribution, all the way to the retailer," he continues. "We are not just selling to grocery stores anymore, we also sell to manufacturers, who in turn use our dairy products as ingredients to make other great products. We're fortunate that dairy-based products offer great nutritional value, and their inherent functionality makes them ideal ingredients for many applications."

As the third generation of a dairy family, the dairy industry has always been part of Hackman's life. "When I began my career with Prairie Farms 17 years ago, I had already gained 14 years of dairy experience through our family-owned and operated dairy processing facility in Jefferson City, Mo. I understand the crucial role of operational excellence in returning value to our hard-working dairy farmers," Hackman says.

In his leadership role, Hackman oversees the Quality, EHS, Engineering, and Operations teams and the company's 47 dairy plants in 18 states. Several states like Illinois operate eight manufacturing plants; Missouri has six plants; Minnesota and Indiana each run four plants. He tries to visit plants at least once a week.

"I grew up in the dairy industry, so it's part of my nature to want to see and hear everything that's going on in our plants. In our operations, we are back to the basics and very employee oriented. It's important to have good employees and good training because we rely on their expertise to keep our plants up and running."

Milk is No. 1 product produced

For Prairie Farms, it's all about the milk. "Milk is the No. 1 product we produce, and I'm very proud that we're the nation's second-largest fluid milk processor," Prairie Farms CEO/EVP Matt McClelland tells Dairy Foods.

“We have small farms and medium farms primarily in the upper Midwest that produce the richest quality milk. We handle the packaging and the distribution, all the way to the retailer. …We’re fortunate that dairy-based products offer great nutritional value”

— Chris Hackman, Chief Operation Officer of Prairie Farms Dairy

In fact, the co-op has 30 fluid milk plants that in fiscal year 2023 processed 7.5 billion pounds of milk, while the 600 family farms in the co-op, with an average of 150 cows per farm, contributed nearly 3 billion pounds, or about a third of the milk supply. Prairie Farms also maintains partnerships with other dairy cooperatives and independent shippers, he adds.

The co-op operates dairy processing plants in 18 states: Arkansas, Illinois, Iowa, Indiana, Kansas, Kentucky, Louisiana, Michigan, Minnesota, Mississippi, Missouri, Nebraska, Ohio, Oklahoma, South Dakota, Tennessee, Texas, and Wisconsin. It also has a transportation company with 5,200 trucks providing coast-to-coast distribution and more than 100 distribution centers.

The red and white Prairie Farms logo with the gold banded "Farmer Owned" packaging is well recognized through distribution channels in 16 states: Alabama, Arkansas, Illinois, Indiana, Iowa, Kentucky, Louisiana, Michigan, Minnesota, Mississippi, Missouri, North Dakota, Ohio, South Dakota, Tennessee, and Wisconsin.

Over the past 15 years, Prairie Farms has continued to experience strong performance and steady growth. In fiscal year 2009, dollar sales were $2.3 billion, in fiscal year 2019, sales stood at $2.7 billion, and in fiscal year 2022, sales climbed to $4.2 billion, according to McClelland. "There's been an 83% increase in dollar sales since 2009," he highlights.

In 2022, the acquisition of Dallas-based Borden Dairy Food Co.'s Texas Holdings enabled the co-op to increase its net revenue by 23% to $4.6 billion, the CEO says. The acquisition – and the company has had 50 in its 86-year history – enabled Prairie Farms to not only diversify its product offerings but to add a few more production plants in Conroe and Dallas, Texas.

And Texas is not the only state with local plants and a significant brand presence. "Within the last six years, we acquired assets in Wisconsin, Minnesota, and Iowa," McClelland explains. "Purchasing the Rochester, Minn., facility expanded our product portfolio to include club cheese, and our capital investment in the Luana, Iowa, facility has allowed us to grow our Swiss and cream cheese business," he continues. "The plants in Faribault, Minn., and Shullsburg, Wis., have long been well known for producing award-winning cheese, and last year was no different. I'm proud to say the Faribault team received the National Milk Producers Federation Cheese Contest Chairman's Award for Cave Aged Rinded Swiss in November."

The production of ice cream mixes that the company sells commercially to local ice cream shops, restaurants, and fast-food places, the production of dozens of different flavors of ice cream, ranging from tried and true classic flavors, like vanilla and chocolate, to specialty flavors, like lemon raspberry cheesecake and cherry chocolate funk to sherbet in a variety of flavors, as well as its North Star Frozen Treats line are other areas where Prairie Farms shines.

"Our ice cream portfolio is amazing, and last year, we sold millions of gallons," McClelland states. "We also extended our popular Premium Small Batch Ice Cream into the novelty category by introducing Small Batch Premium Mini Ice Cream Bars. Just like our ice cream, each bar starts with the basics – milk and cream from our family-owned dairy farms."

Hackman notes that when plants are singularly focused on one specific dairy product, such as the co-op's award-winning cottage cheese, they can streamline the production of the best cottage cheese in the country.

"Volume-wise, we make millions of pounds of cottage cheese monthly in several cottage cheese plants in Carbondale, Ill., Quincy, Ill., Fort Wayne, Ind., Wichita, Kan., Chandler, Okla, and Kansas City, Mo."

McClelland states that when Prairie Farms puts its cottage cheese against the best of the best brands, it routinely garners major awards. "I am biased, and I try to stay humble, but especially in our cultured products, I believe we're best in class," he says. "We have cheese cooks that have been making cottage cheese in our plants for years, if not decades. These men and women are artists.

"While producing cottage cheese hasn't changed that much over the years, the cooks are the ones to determine what to add or take away," he continues. "It really is an art form with open vats. But what makes a difference for us is that our employees love to make cheese, and because they love to make it, they make great cheese."

To keep up with consumer demand for lactose-free products, this spring Prairie Farms is launching new lactose-free products: cottage cheese and sour cream in 15 states and lactose-free milk gallons in metro St. Louis, with other states to follow in June.

Different pasteurization methods

While dairy recipes may vary in minuscule ways, the co-op maintains consistent formulas for recipe development that the entire company employs.

"We always start with the highest quality milk. The nuances to process fluid milk plant-to-plant would be speed," Hackman explains. "Some plants might process at 2,700 gallons an hour, and others might be at 8,000 gallons an hour. There are differences in equipment size and capabilities, as demonstrated by our ultra-high temperature (UHT) processing." Hackman also notes that with UHT milk, it's all about time and temperature.

Prairie Farms has UHT plants in Battle Creek, Mich., and Granite City, Ill. The Michigan plant processes milk in a wide variety of flavors, including Chocolate, Salted Caramel, Strawberry, Chocolate P&B, Chocolate Malt, and a new single-serve iced coffee that debuted in February. The Granite City plant processes fluid milk, iced coffee, whipping cream, half & half, egg nog, and custard.

"With UHT, you are processing at a higher temperature, which has a higher kill rate on the bacterial content, which simply allows for a longer shelf life," he explains. "Once the packaging is opened, it's back to a normal fresh-type product. Because of the longer code date, we can ship UHT products across the U.S."

Prairie Farms is committed to building relationships with various distribution channels that will utilize their own networks to reach new markets for Prairie Farms products. "We're working with these channels because we know it's continuing to increase in popularity and solves the problem of getting the products to customers who don't have it at the grocery level," McClelland says. "It’s a creative solution to a challenge.”

In addition, Prairie Farms has a line of extended shelf life (ESL) pantry fresh products with a 12-month shelf life, the CEO says, adding that the company is also exploring how to make value-added, longer shelf-life products to bring added growth to the co-op.

“If I had to relay to a customer why they should buy our milk, it’s because our milk is supporting local dairy farmers who are in turn supporting their communities,” McClelland concludes. “Even though we’re trying to grow the brand and become a national player, it all starts with the local community. I’d tell everyone to drink their milk and support their dairy farming community.”

.png?height=200&t=1663254269&width=200)