The casual visitor to Athens, Tenn., would have no idea that dairy products produced here are shipped throughout United States. Even residents of this small town, located in the southeast corner of the state, probably do not know that Mayfield Dairy Farms makes ice cream for other companies to sell in groceries stores across the country.

Mayfield’s dairy plant, located just north of downtown Athens, is a sprawling complex. Drivers of milk tankers check in at one building before unloading at the plant. On one side of Madison Avenue, raw milk is processed into white milk, chocolate milk, buttermilk and other fluid products. In another section of the plant, some of the 200-plus employees also manufacture a wide range of ice cream products, ranging from 14-ounce containers to 3-gallon foodservice tubs.

Across Madison Avenue, a blow-molding operation is constantly manufacturing Mayfield’s iconic bright, opaque yellow jugs that preserve the milk’s freshness by blocking out the UV light that breaks down nutrients and affects milk’s taste.

Mayfield Dairy Farms is one of the operating units of Dean Foods Co. The Dallas-based company is the second-largest processor on the Dairy 100, this magazine’s annual ranking of dairies doing business in North America. Corporate revenues in 2014 totaled $9.5 billion. But measured by plants, Dean Foods is the largest. It has 67 facilities manufacturing fluid milk, ice cream and cultured products.

The Mayfield division serves nine Southeastern states. It also operates a milk plant in Braselton, Ga., and an ice cream plant in Birmingham, Ala. Mary Williams is general manager of the Mayfield division. Scott Watson is the plant manager of the Athens operation.

They and the 205 production employees in Athens have their work cut out for them. That’s because Mayfield recently landed ice cream business in Florida and Louisiana since no Dean division was serving those states with ice cream. That new business keeps the freezers churning, as does the co-manufacturing agreement with Boardwalk Frozen Treats to produce Baskin-Robbins’ 14-ounce containers sold at grocery stores throughout the United States. (The Birmingham plant manufactures Baskin-Robbins foodservice tubs for scoop shops in 43 countries.)

On the fluid side, Mayfield bottles Dean’s DairyPure white milk and TruMoo chocolate milk products. These are co-branded with Mayfield’s name.

Blow-molding plastic milk jugs

Mayfield produces its own half-gallon and gallon jugs. It has six blow molders of varying capacities, from four-head to eight-head machines. Mayfield bottles its milk in bright yellow jugs, which protects milk from degradation by ultraviolet light. The equipment also makes jugs in “natural” plastic for private label customers. Besides producing bottles for this plant, Mayfield is making plastic containers for sister plants in Braselton and Birmingham.

Because the fillers can fill bottles faster than the blow molding equipment can make them, Mayfield needs to keep a steady supply on hand. Bags of 48 gallon jugs and 108 half-gallon jugs are staged in this room. Fully automated baggers wrap the bottles in plastic. Likewise, fully automated de-baggers remove the plastic and place the bottles back on the conveyor system that supplies the fillers.

The dairy also bottles milk in plastic pints and half-pint bottles. (A large customer is McDonald’s restaurants, which buys white and chocolate milk in the half-pint size.) Bottles arrive from suppliers and are fed into a hopper and then onto conveyors. The bottles go through a labeling machine and a shrink tunnel. An unscrambler puts the bottles in single file order and they then move to an accumulation table and file up an elevator to the filling room. A performance improvement team looked at ways to improve this process and tweaked the equipment to make the bottles flow more smoothly through the system. Another improvement eliminated jams on the elevator.

Receiving milk, orange juice, sugar

Mayfield receives 25 to 28 milk tankers a day, every day of the week, from 7:30 to 3:30. Tankers from nearby farms pull into a building across the street from the plant before they off-load the milk. Tankers are weighed on a truck scale and Mayfield draws samples. If the milk passes organoleptic and antibiotic tests, the trucks proceed to the four-bay receiving area at the plant. After unloading, the trucks are washed and sent back on the road. Mayfield also takes in orange juice concentrate at this receiving area; another part of the plant accepts deliveries of liquid sugars.

At another receiving area of the plant, empty milk cases return from customers. Two lines of conveyors feed the cases into an ultrasonic case washer. The ultrasonic action knocks the dirt off the cases, which are then washed, sanitized and stacked. Later, these clean cases will be filled with product and staged in the cooler. In the cooler, there are two palletizers staging the cases for delivery.

The plant in Athens has capacity to store 275,000 gallons of raw milk. It has four 10,000-gallon pasteurized tanks and two 15,000-gallon tanks. In addition, the plant stores cream in four 5,000-gallon tanks. Because Mayfield also makes ice cream here, it occasionally has to buy additional cream. One source is Knoxville milk processor Weigel’s (which was featured in the April 2012 issue).

The processing rooms have three high temperature/short time pasteurizers for milk and one for ice cream. It has three separators, which range in capacity from 4,000 to 9,500 gallons per hour. Buttermilk is a popular beverage in the Southeast, and Mayfield is up to the task of supplying its customers with the cultured drink. There are enough vats to make almost 15,000 gallons of buttermilk per day. The tangy dairy beverage is also used to bake buttermilk biscuits. The Cracker Barrel restaurant chain is a customer, buying buttermilk in half-gallons to be used in its biscuit recipes.

The filling room was abuzz during Dairy Foods’ visit. Mayfield has nine fillers, including a 24-valve unit for plastic half-gallons, a 30-valve unit for plastic gallons and a 36-valve unit for plastic 8-ounce and pints bottles. There are three half-pint fillers that can also accommodate 4-ounce paper containers. Mayfield puts labels on the front and side of its branded gallons. Gallons made for other customers receive only a front label.

Record rates of production, by machine, are noted on plaques installed around the plant. The boards note the machine, the throughput achieved and the team members operating the filler and its support equipment at the time.

Mayfield makes ice cream, too

As noted above, not many fluid milk plants also make ice cream. Besides making a full range of ice cream products (from premium to light to no sugar added), Mayfield also makes frozen yogurt and a frozen dairy dessert called Snow Cream.

Ice cream production starts at 6:30 a.m. An operator in the control room dials in the mix. Dry ingredients and packaging come from a 30,000-square-foot off-site warehouse.

Milk, cream, condensed milk, sugars and powders are blended in any of the three 2,000-gallon batch tanks. After the powders are fully hydrated, the mix is pumped to the pasteurizer and then to the flavor vats, where colors and flavors are added. Certain flavors flow from large pressurized totes. Mayfield used to pour flavors by hand from gallon jugs but the totes allows for more precise dosing. Mayfield uses a liquid chocolate that “explodes” into chips when it hits the cold ice cream mix, said Scottie Mayfield, a grandson of the founder and the company’s chairman emeritus.

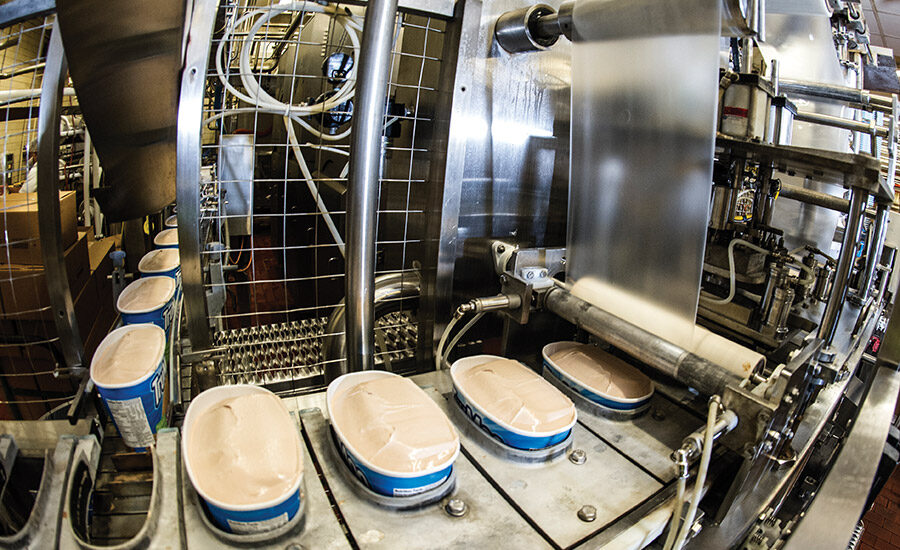

On the day of our visit, operators were filling 48-ounce scrounds (which receive an inner seal), 56-ounce bricks and 3-gallon tubs. The plant also fills 14-ounce paper containers for Baskin-Robbins. Novelties are produced in the Alabama plant.

Mayfield makes the 3-gallon paper tubs used by foodservice accounts. It used to use a metal ring to hold the top and bottom of the can in place. For safety reasons (cut fingers), the dairy changed to metal-less cans. Instead of a metal ring, the cans are held together by a plastic rim on the top and a food-grade glue on the bottom.

Once filled, the packages have codes printed on the container. They pass through a vision system to assure that the lid and the cup match. Then they pass through metal detectors and checkweighers.

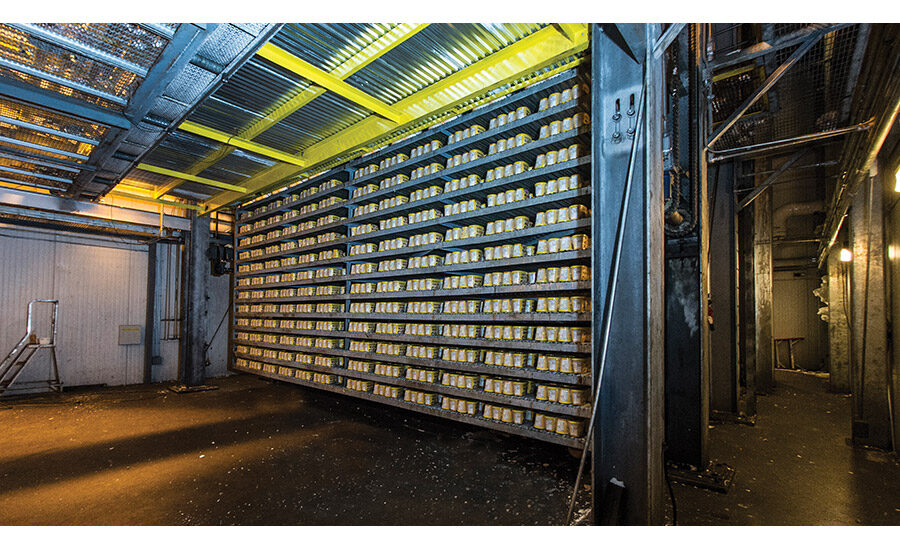

Then the packages are conveyed to the hardening room. Mayfield has two methods to get the ice cream to a rock-hard state. One is a blast freezer (the dairy has two units) and the other a plate hardener. In the frozen warehouse, one-rim and two-rim cranes pick pallets for delivery to customers. The customer base is growing. In the last year, Mayfield added supermarket customers in Florida and Louisiana. Those were significant acquisitions; no Dean division had been serving those states with ice cream.

In addition to making sure the equipment runs properly, Watson keeps watch on food safety and employee safety. In the on-site quality control lab, the technicians are testing both fresh and frozen finished products. The lab tests samples throughout the day to assure consistency. The lab is also performing tests for butterfat, solids and brix. Then there are tests for coliform, direct micro count (DMC) and psychrotrophic organisms. Watson also said there are hanging drop, phosphatase and allergen verifications tests. For packaging, there are die checks on half-pint cartons of school milk and fill weights. Technicians cut open ice cream packages to look for proper distribution of inclusions and variegates. There are also taste tests and other organoleptic examinations.

Depending on the test, near infra-red lab equipment can provide the results in seconds. But when they need to, lab technicians can conduct the slower Babcock tests that every food science major learned in college.

Regular communications

Plant managers hold regularly scheduled daily and weekly meetings to identify issues and upcoming production needs. Line employees go through monthly training on plant safety and food safety, and are tested with paper or online tests to gauge their comprehension. Each department (such as receiving, processing or filling) tracks key performance indicators. The results are displayed on white boards outside the manager’s office. Those written in green are results that meet or exceed targets. Those written in red indicate improvement is needed.

Four communication stations, consisting of flat-panel televisions, are set up in employee break rooms throughout the plant. Watson can push out messages of interest to employees, as can the corporate office.

Both the fluid side and the ice cream side of the plant have earned Level 3 certification in the Safe Quality Foods initiative. In addition, the federal Food and Drug Administration inspects the plant, as does the Tennessee Department of Agriculture. Dean Foods has its own quality audits of its 60-some processing plants. This intramural competition keeps each plant manager striving to improve.

Mayfield’s Birmingham plant received the Dean Foods CEO Quality Award for ice cream in 2013 and 2014. Criteria include SQF scores, training participation and consumer complaint improvement. The judging committee also considers quality innovations, best practices and company culture. Eddie Allen is the plant manager in Birmingham.

In announcing the award in May, Dean CEO Gregg Tanner said, “Dean Foods holds its plants to very high standards, making for particularly stiff competition surrounding this award. We are delighted with Mayfield’s excellence in protecting quality from farm to table, and we’re proud to hold them up as an example for the second year in a row.”

Mayfield has been making dairy products since 1923. At that time, only residents of McMinn County, Tennessee enjoyed them. Today, consumers across the United States and throughout the world enjoy the dairy foods and beverages made in Athens, Birmingham and Braselton.

At-A-Glance

Mayfield Dairy Farms, Athens, Tenn.

- Interstate Milk Shippers plant 47-131

- Raw milk score 90; enforcement score 97 (July 2015).

- Year built: 1950

- Products made: milk, buttermilk, orange juice, teas, lemonades, ice cream, frozen yogurt

- Production employees: 205 in the milk and ice cream plants

- Pasteurization: high-temperature/short time

- Milk fillers and formats: 9 fillers, including two 24-valve units – one for plastic half-gallons and another one for plastic quarts; a 30-valve unit and a 28-valve unit for plastic gallons, 36-valve unit for plastic 8-ounce and pints bottles. There are three half-pint fillers that can also accommodate 4-ounce boxes and a dispenser bag filler.

- Ice cream fillers and formats: 7 fillers, 14-ounce and 16-ounce containers, two 48-ounce scround fillers, 56-ounce bricks, 4 quart pails, 3-gallon foodservice tubs, quarts and half gallon round plastic

- Blow molding: 6 blow molders with four, six and eight heads

- Raw milk storage capacity: 275,000 gallons

- Pasteurized milk storage capacity: 90,000 gallons

- Warehouse: 30,000 square-foot offsite facility

Photos by Vito Palmisano