Featured Product Advertisement

These announcements about dairy processing equipment, packaging systems, lab tests and equipment, and ingredients for dairy foods and beverages are written and sponsored by the manufacturers.

ARTICLES

advertisement

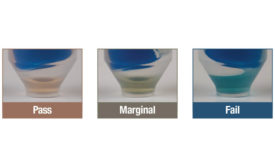

CHEMetrics Introduces a NEW Verification Kit for 530 nm Single Analyte Meters

May 27, 2016

advertisement

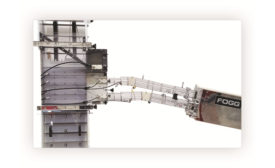

Triangle’s Model XY-RJ VFFS Bagger Now Available with Ultrasonic Sealing

Run multiple package styles, with heat or Ultrasonic sealing

April 25, 2016

advertisement

A Revolutionary Yeast & Mold Test for Dairy Products in Less Than 4 Hours

April 11, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing