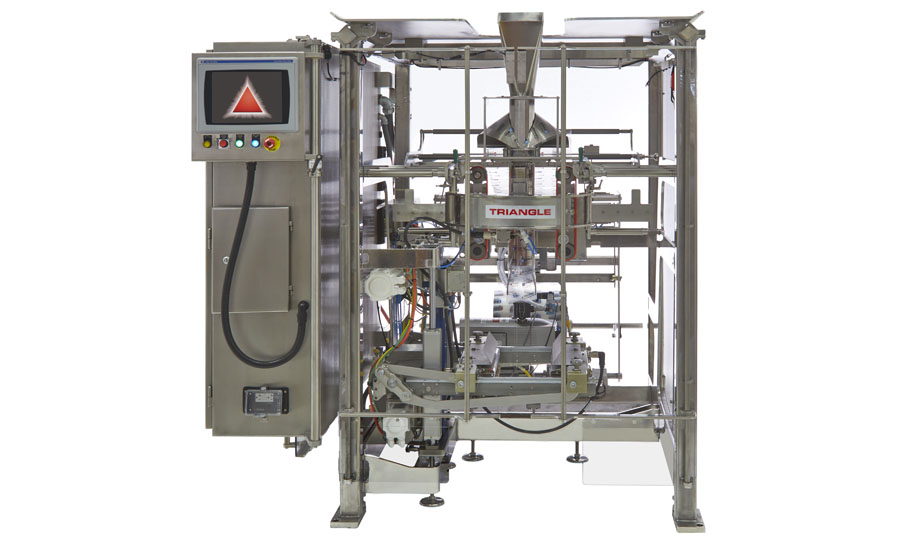

Triangle Package Machinery Co. has added optional Ultrasonic sealing to its new Model XY-RJ, a vertical form fill seal bagging machine designed to run a wide variety of bag styles. Since its introduction in late 2015, the versatile bagging machine has attracted considerable interest because of its easily rotatable sealing jaw. Model XY-RJ can run pillow bags, gusseted bags, 3-sided seal and Doy bags, and now offers the flexibility to seal bags with Ultrasonic welding or traditional heat sealing.

The newly-enhanced VFFS bagger will make its debut at the United Fresh show in Chicago, June 21-22, 2016. “The addition of optional Ultrasonic sealing provides a terrific advantage that our produce customers cannot find elsewhere,“ states Ralph Hernandez, VP – Sales & Marketing, Triangle Package Machinery Company. With Ultrasonic sealing, a bagger can seal right through product for a completely product-free and airtight seal. The benefits include product and labor savings, as well as film and material savings.

Other key features of Model XY-RJ include:

- Easy-to-rotate sealing jaw requires no heavy equipment or complicated tools – switch formats in 15 minutes or less;

- Ability to run supported (laminated) and many non-supported film structures;

- Bagging speeds up to 120 bpm;

- Optional Longitudinal Zipper.

Technically advanced and operator friendly, the new bagging machine can run in intermittent or constant motion, and offers Triangle service and quality. Markets include produce, powders and sugar, poultry, meat and seafood, and IQF products, as well as confectionery, snack products, and more.

Triangle will be exhibiting the Model XY-RJ vertical form fill seal bagger with Ultrasonic sealing at the United Fresh Show in Chicago, June 21-22, 2016. Visit us in Booth 2611 for a demonstration.

About Triangle

Triangle Package Machinery is a U.S. manufacturer of vertical form fill seal (VFFS) bag machines, combination weighers, horizontal cartoning / bag-in-box systems, and tray loading / depositing systems. Founded in 1923, Triangle is headquartered in Chicago, IL, and offers a 120,000 sq ft facility that houses its entire manufacturing process from raw material fabrication through complete machine testing and checkout. Triangle also provides superior after sales support, training, documentation, and online troubleshooting, as well as spare parts service. For more information on Triangle's equipment and service capabilities, visit us online at www.trianglepackage.com, or call (800) 621-4170.