Home » Keywords: » milk testing

Items Tagged with 'milk testing'

ARTICLES

The critical factor is the generation time of any bacteria that may be in the product

Read More

Dairy supplier news

DSM showcases its milk testing capabilities at SPACE 2016 in France

The SPACE tradeshow takes place in France Sept. 13-16.

August 10, 2016

The 16 tests you need to perform on raw milk, finished products

Testing raw milk ensures you are receiving a high-quality product. Testing finished product protects consumers.

June 16, 2016

Dairy conference

How will expanded drug-residue testing affect grade ‘A’ products?

IDFA adds a new session to the Milk and Cultured Dairy Products Conference

May 2, 2016

Testing and equipment

Arla Foods installs Mocon’s Greenlight Instrument in UK dairies to speed ESL milk spoilage testing

September 24, 2015

Obituary

Henry Randolph, an expert in milk testing and food safety, has passed away at age 78

Mr. Randolph was the President/Founder of Randolph Associates, Inc., established in 1977. He was a renowned Food Scientist among the Food and Dairy Industry, affectionately known as the "Milk Doctor."

July 31, 2013

Equipment

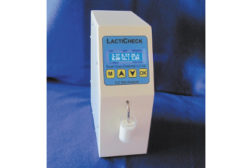

LactiCheck’s new RapiRead milk analyzer gives reliable results in seconds

July 15, 2013

A new testing concept is on the horizon

Metagenomics technology could become a valuable tool for dairy plants to quickly identify root-cause solutions to microbial problems.

April 21, 2013

Beta-lactam test

DSM test analyzes milk samples, measures traces of beta-lactam

March 14, 2012

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing