PACK EXPO, North America’s largest packaging and processing trade show, achieved record attendance this year, according to show producer, PMMI, The Association for Packaging and Processing Technologies.

The event, which took place Sept. 11-13, in Las Vegas, drew some 32,000 attendees, who attended the show that featured more than 2,300 exhibitors across 1 million net square feet of exhibit space at the Las Vegas Convention Center. It was the largest PACK EXPO Las Vegas in the show’s history.

PACK EXPO Las Vegas offered multifaceted solutions for the more than 40 vertical markets represented at the show. Attendees were also able to visit the new Sustainability Central exhibit to learn more about the sustainability process, and could sit in on more than 130 educational sessions.

During the show’s second day, 750 industry professionals gathered for the Packaging and Processing Women’s Leadership Network (PPWLN) breakfast. Keynote speaker Manjit Minhas, a Canadian entrepreneur, beer baroness and television personality covered mentorship, being a working mom, starting her business, the importance of being fearless, and constant learning.

“It takes coordination and participation from all parts of our industry to pull together an event of this size and caliber. We’re extremely grateful to all involved in making this show a record-breaking success,” says Laura Thompson, vice president, trade shows, PMMI. “The feedback from exhibitors and attendees is encouraging, especially hearing success stories from both first-time and long-time participants.”

Here are 15 product solutions that were featured at the event, as well as one news announcement.

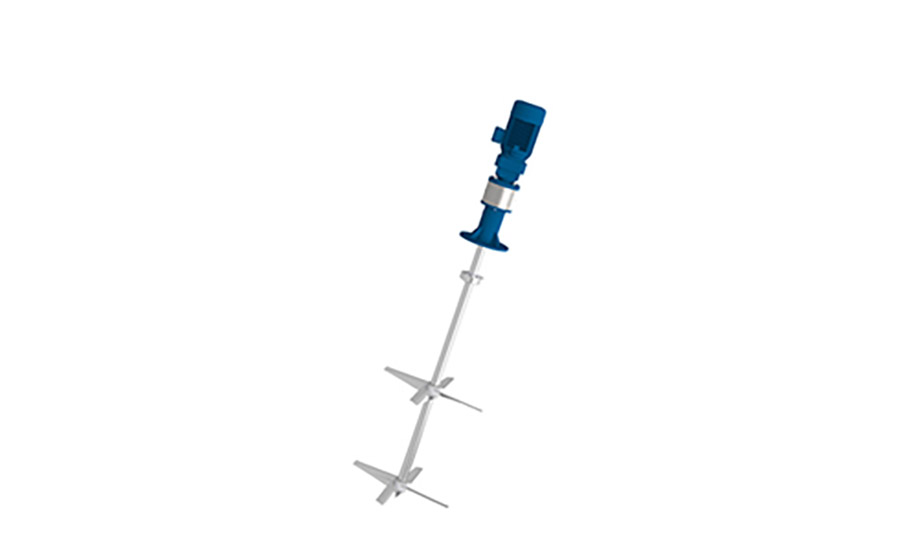

HYGIENIC AND INDUSTRIAL MIXING EQUIPMENT

Admix now offers its Rotomaxx III and Rotomaxx III CX, the high efficiency, slow speed agitator designed for both the chemical/industrial and the hygienic/sanitary industries. The Rotomaxx III and Rotomaxx III CX are designed for the most demanding operating environments for hygienic and chemical applications, the company states. The modular design allows for multiple impeller, shaft diameter, gear ratio, and motor horsepower combinations, with designs that can handle tank volumes up to approximately 100,000 gallons. It provides a customizable mixing solutions for many application needs.

HAND-HELD MEASUREMENT GAUGE

Agr International Inc.’s ThicknessPen is a handheld measurement gauge that is compact, rugged, and simple to use. Developed to address the multiple and diverse thickness measurement applications of the production environment, the ThicknessPen can be used just about anywhere, from the laboratory to the plant floor or even in a wet environment at a job site in the field. The patent-pending dual-mode design affords operation with or without a target ball. This provides a unique versatility not found in any product in this marketplace, while still providing the precision necessary for the laboratory and the portability, ruggedness, and safety for use on the production floor.

AUTOMATION SOLUTIONS FOR READY-TO-DRINK BEVERAGES

Allpax, a ProMach brand, offers retort and retort room automation solutions for ready-to-drink (RTD) beverages. New products include its Rotary Steam-Air and ImmersaFlow retorts and robotic handling systems. The Allpax Rotary Water Immersion Retorts controls the sterilization process for RTD beverages for companies producing low-acid, shelf-stable drinks such as milk-based coffee, tea and energy drinks packaged in a wide variety of containers. Allpax designs and manufactures 100% of its retort room automation systems, reducing labor, increasing worker safety, and ensuring optimum productivity. Its Model 2402 Multimode R&D Retort is a compact, versatile unit that helps processors bring new shelf-stable ready-to-drink beverages to market more quickly and with higher levels of quality. The 2402 can be equipped with the rotary agitation module, which offers greatly reduced come-up, sterilization and cooling times, resulting in very high levels of product quality, especially for those products that are dairy-based like RTD coffee beverages.

ALL-FIBER BOTTLE SOLUTION

CelluComp and Rypax together have introduced an all-fiber bottle solution with an interior coating that offers a biodegradable and renewable solution for a widely-used packaging design. Using precision plant-based packaging production with a highly renewable feedstock ingredient, the companies have created the all-fiber bottle with a novel pulp fiber made with a mix of Curran, bamboo and bagasse. This material is extremely strong with minimal porosity and allows the application of a thin, impermeable coating to the bottle’s interior, which allows manufacturers to take the next important step in environmental packaging by eliminating the need for a plastic liner, the company says. Currently designed for water and powder substances, production will include industry applications in food and beverages.

FLOOR TO CLOUD PACKAGING SOLUTIONS

Software and engineering company Emerson offers a variety of Floor to Cloud packaging solutions for smarter packaging lines and more efficient processes that make it possible for manufacturers to continuously improve plant productivity, sustainability and safety. The company’s Floor to Cloud portfolio includes products from its Aventics, Branson, Movicon, PACEdge and PACSystems solutions. Packaging automation experts demonstrated at the show how a Floor to Cloud approach can unlock trapped data and connects islands of automation, giving manufacturers the visibility and control to solve critical challenges and ambitious goals. By improving overall equipment effectiveness (OEE), companies can increase energy efficiency while reducing waste, and create safer operations and digital record keeping, the company says.

ROBOT AND COBOT SOLUTIONS

The DR-3iB/6 from FANUC is a stainless steel food-grade delta robot for picking and packing primary foods. Rated IP69K, the robot complies with U.S. national food safety standards, which will help companies increase their production efficiencies without compromising food safety. Equipped with a Soft Robotics gripper, the robot picks up food products and reorients them onto an outfeed conveyor with trays. The cell features high-speed picking with product re-orientation. The DR-3iB/6 Stainless features a fully enclosed stainless-steel body that is resistant to the chemicals, high pressure and temperatures required in strict washdown environments. It has a 1200mm reach (450mm height) and a powerful four-axis design that allows it to handle up to 6kg payloads at high speeds. The robot’s mirror-like surface finish ensures that any microbial contaminants can be washed away cleanly, the company notes.

FOOD SAFETY AND SANITARY DESIGN

The Mag Lock Strainer is an option on any FoodSafe Drains Catch Basin or Area Drain because it solves the issue of having garbage or foreign objects enter the drain line. The company also offers its patented Slot Hog, a direct connection mobile funnel that can be placed anywhere in the drain line to make emptying vessels a breeze. It also protects floors from high heat and harmful chemicals that might otherwise cause long-term damage.

HIGH-PRESSURE PROCESSING (HPP) EQUIPMENT

HPP, also known as high pressure pascalization, or cold pasteurization, is a non-thermal, post-packaging (5ºC – 20ºC) food and beverage preservation method that guarantees food safety and achieves an increased shelf life while maintaining the optimum attributes of fresh products. Hiperbaric’s HPTP technology uses a proprietary basket combining high pressure and thermal processing to create premium-quality, shelf-stable packaged foods and beverages, including dairy products.

HEAT-SEALING MACHINE

JBT’s Proseal launched its XTRs entry level heat-sealing machine. The XTRs is a semi-automatic, two-station rotary table, capable of sealing 30 packs per minute with a two-impression tool without the need for compressed air. The plug-and-play solution is easily operated, featuring a Human Machine Interface (HMI) that offers multi-language settings, as well as diagnostics and alerts that are automatically recorded to an audit trail. The HMI also allows for recipe-driven product change and an automatic tool lock. The XTRs’ all-electric sealing capability enables a more consistent and efficient seal force, reducing energy usage and total cost of ownership for the user. Re-designed to meet the demands of today’s food production industry, the machine offers users tool loading from the front of the machine, which simplifies tool changeover, and is compatible with legacy GTR tooling.

CASE AND TRAY LOADER

JLS Automation offers its flexible Hawk case and tray loader that features a compact design with a robotic top-load solution for the food and beverage industries. With a small footprint, the Hawk maximizes existing production floor space. Along with standard case and tray loading, it works well with flow-wrapped or bagged products, trays, bars, clam shells, bottles, cans and many additional formats. Stainless-steel construction and three levels of washdown protection are available, and its toolless changeover allows recipe changes to occur in less than one minute, providing greater uptime and production, the company states. A cantilevered design allows for easy integration into current packaging lines with existing conveyance, but is just as easily provided for new installations as well. Infeed variations can be tailored to product type, and it can handle a variety of primary and secondary packages. As an added feature, corrugated or paperboard divider inserts can also be loaded for layering, with or without support flanges. A vertical packing solution for rigid containers is also available.

ORDER FULFILLMENT SOLUTION FOR STORE PICKUP AND DELIVERY

The XpressPickup System (XPP) from Orbis combines durable totes with a versatile dolly and cart for convenience and mobility. The system is engineered to support in-store order fulfillment and offers a seamless integration with existing BOPIS (buy online, pickup in store) operations. Its tote design and enhanced dolly and cart capabilities enables retailers to achieve quicker turnaround times, from order placement to in-store fulfillment to curbside pickup. It was designed to optimize store operations, space and employee safety, and help streamline in-store operations. The XPP tote limits spillage of damaged or open products, and the compact 24-inch by 16-inch by 11-inch footprint maximizes picking efficiency. Built-in bag hooks provide support for efficient picking and curbside delivery. The XPP tote accommodates all types of merchandise and can be used with standard metal carts.

R.A Jones

FLEXIBLE TRANSFER SYSTEM FOR POUCHING AND CARTONING MACHINES

The intelligent Flexible Transfer System (iFTS) from R.A Jones, a Coesia Co., is a smart automated and customizable transfer system that provides companies with a reliable and flexible solution to solve simple or complex automation challenges, the company states. Offering the standard building blocks, iFTS uses a comprehensive library of fixed automation, various robot types and sizes, and standard or custom tooling to optimize a solution to meet production needs and improve efficiency within the packaging line. The system integrates a four-axis robotic pick-and-place, offering enhanced pouch size change flexibility, and depending on sizing, product can span across two magnetic shuttles. By rotating and collating products so more can fit in the carton, iFTS can help brands cut down on overall carton volume by 10% to 20% and create a more sustainable packaging option.

PARTNERSHIP FOR COMPOSTABLE PACKAGING

Compostable packing company TIPA and CNG (Charter Next Generation), a U.S. specialty film manufacturer, announced a partnership to drive local U.S. production and adoption of compostable packaging. TIPA has collaborated with other U.S. manufacturers in recent months, and is also launching a new compostable packaging film exclusive to North America, which CNG will manufacture and which will be used for food and consumer goods. By facilitating the local production of compostable packaging, the partnership also contributes to reducing the world’s carbon footprint by eliminating the traditional need for brands to ship packaging from abroad, the companies maintain. Under the partnership, CNG, will produce two films from TIPA’s proprietary compostable materials: TIPA’s newly-launched TIPACLEAR 301 and its TIPACLEAR 319. Both are highly transparent home compostable films for food and consumer goods packaging, available in various thicknesses and applications.

Unibloc

Unibloc Hygienic Technologies has expanded its popular Slimline product line with its new Flotronic Slimline 14-inch AODD Pump. The Flotronic Slimline fully meets clean-in-place (CIP) sanitation procedures and is the first 14-inch AODD pump that can be cleaned in place using an external CIP rig. The company also recently announced the addition of its biggest hygienic lobe pump to date. The UltraLobe FoodFirst 700 Series pump doubles typical flow throughput. The pump delivers the same quality as the popular Unibloc 600 Series but significantly increases volume and throughput for the processor. All within a similar footprint, the Unibloc UltraLobe gently handles larger, shear-sensitive food products with no sacrifice in product integrity. Delivering a flow rate of up to 1,170 GPM, the Unibloc 700 Series is ideal for food and beverage applications.

Coding, marking and printing solutions company, Videojet Technologies, offers its latest product advancements that help manufacturers simplify their digital factory journeys. Videojet experts will demonstrate Industry 4.0-enabled innovations in continuous inkjet (CIJ) printers, laser marking systems, thermal transfer overprinters (TTO), thermal inkjet (TIJ) printers, case coders, print and apply labelers, vision inspection and both Wi-Fi and cellular cloud connectivity solutions. As part of its core commitment to innovation, connectivity and sustainability, Videojet is focused on developing and enhancing digitally enabled solutions for remote service and support, sensors, marking and coding control systems, vision systems and software for IoT and Industry 4.0 applications. The company aims to help its customers drive to new levels of productivity, security and operational efficiency.

FILLING AND SEALING SOLUTIONS

Waldner North America offers German-engineered filling and sealing machinery that can increase productivity while lowering total cost of ownership, the company suggests. The company’s program, Waldner Sense, provides customers with insights to make smart, ecological choices on packaging materials, designs and the production process. Its Waldner Care complementary aftermarket care program offered to Waldner customers in North America eases the burden of skilled maintenance and helps ensure that preventative maintenance is performed on schedule. The program also helps maximize profits and efficiency while minimizing unplanned downtime.