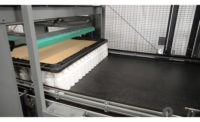

Parallel accumulation systems reduce downtime

At Pack Expo in September, Multi-Conveyor showcased its accumulation system featuring Alpine incline and decline, pneumatic divert and product-reject technologies. Alpine systems offer a narrow footprint with simplified designs using standard conveyor components and controls. Products are elevated and declined to minimize use of floor space. This particular system was designed to run at 60 feet per minute at 60 hertz based on a product load of 1 pound of distributed load per lineal foot of conveyor with 100% accumulation.

800-236-7960; www.multi-conveyor.com

Hygienic filler, sealer and capper with minimum footprint

At Pack Expo, Bosch Packaging Technology launched the next-generation Osgood RFS-Series for hygienic filling, sealing and capping of a wide range of dairy and other food products. The machine allows for efficient and accurate dosing, as well as quick product changeovers. It can be equipped with the latest HMI 4.0 for simplified workflows and easy operation. The four-lane RFS-4001 fills cups at speeds of up to 160 cups per minute (9,600 cups per hour) and is a good alternative for producers with limited production space. It’s available in both clean and ultra-clean execution.

813-855-7337; www.boschpackaging.com

High-speed capping machine with brushless technology for pump bottles

Serac introduced a high-speed capping machine for pump bottles that relies on brushless technology, offering maximum efficiency during production, whatever the closing system. The eMC (electronic motion control) capper is designed to meet the ramp-up needs of manufacturers that require quick changeovers with concentrated production runs. Configured with 12 heads, the eMC capper will be able to reach an output of 420 pump bottles per minute, which translates to 35 pumps per minute for each of the capping head.

630-517-5601; www.serac-usa.com

Sterilization unit for HDPE bottle moil

Claranor designed a new sterilization unit for HDPE bottle moil. Puls’Combi HDPE equipment is composed of two optical cabinets — one for the bottle moil sterilization and one for the cap sterilization — both linked to the same electronical bay. This solution offers an efficient and cost-attractive alternative to conventional chemical sterilant spraying. It enables a manufacturer to sterilize the external surface of an HDPE bottle neck before cutting the moil prior to filling.

+33 (0)4 86 40 84 60; www.claranor.com

Second-generation ultrasonic longitudinal seal module

Herrmann Ultrasonics completely reworked its module LSM Fin for continual longitudinal seals and chained bags on VFFS and HFFS. The longitudinal seal module LSM Fin delivers high sealing speeds, thanks to its long exposure area, and does not require synchronization with the film feed, as would be the case with rotating solutions. The anvil can be easily removed using a quick-release system. Different contours are available and parallel seals are also possible. The sealing blade is easy to replace, while the parameter settings are retained.

630-626-1626; www.herrmannultrasonics.com

Child-resistant resealable closure for flexible packaging

Zip-Pak debuted its new Tab-Lok child-resistant resealable closure at Pack Expo. Tab-Lok is a Zip-Pak reclosure for the flexible packaging industry. Tab-Lok recently obtained Conformity of Packaging according to both US 16 CFR 1700.20 and ISO 8317 standards from IVM-childsafe. This designates it an accredited child-resistant resealable solution throughout the United States and Europe. The closure solution is cost-effective and easily integrates into a customer’s current manufacturing operation without significant changes to equipment or capital investment.

800-488-6973; www.zippak.com

Cartridge magnet is 20% stronger and has 25% more reach out

Bunting Magnetics Co. introduced its NUHI cartridge magnet. Completely redesigned to address processing challenges, the Neodymium Ultra High Intensity cartridge magnet is nearly 20% stronger and delivers 25% more reach out than the company’s previous cartridge design. The result is more power, a purer product and better plant efficiency, said the company. The cartridge is built of solid 316 stainless steel and is standard on the company’s magnetic separation products, including its industry-leading HF drawer filters and grate magnets.

800-835-2526; www.buntingmagnetics.com

Continuous inkjet printer for high-speed, medium-duty application

Videojet’s new 1860 continuous inkjet printer (CIJ) uses innovative predictive capabilities, including an ink build-up sensor, to provide up to eight hours of advanced notice of common potential fault conditions that can impact OEE and uptime. Users can count on enhanced predictability and performance — achieved through advances in CIJ printing technology integrated with new on-board intelligence and communications abilities. More than 50 real-time sensors continuously monitor over 150 key indicators of printer performance to provide diagnostics, analytics and guidance. The 45-degree slanted printhead design delivers increased versatility through easy line integration and more mounting options than a 90-degree printhead.

877-781-7133; www.Videojet.com