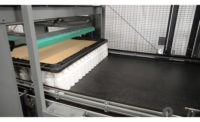

COMPACT PALLETIZER

For plants with limited floor space or a small budget, A-B-C Packaging Machine Corp. says it offers a compact palletizer that is a simple and economical solution for increasing production and eliminating the cost and liability of manual operation. The palletizer occupies from 10% to 30% less floor space than conventional low-level palletizers do. Manufacturers will have the freedom of on-floor operation with an open profile for easy access and maintenance and full machine guarding. It is designed for long-term operation with heavy steel-frame construction, a reinforced and counterweighted elevator table, and a dual chain-driven layer-transfer mechanism.

800-237-5975; www.abcpackaging.com

TOTE-EMPTYING SOLUTION

Central States Industrial says the TrueClean ToteTilter is the solution for processors searching for a cost-effective and safe method to empty totes with less product waste. The ToteTilter uses pressurized air to gradually raise the tote as its weight decreases. This tilting feature allows the product to collect on the valve side of the container for a more thorough evacuation. Equipment safety is a primary concern, and the ToteTilter’s hand and optional foot valve enable operators to start the automated tilting process at a distance and minimize pinch-point hazards.

417-831-1411; www.bit.ly/3oA3rxM

CASE PACKER FOR MANY FORMATS

Delkor’s Performance case packer is engineered to handle a wide variety of primary package formats. It can handle many applications, including rigid bottles, containers, tubs, pouches, cans and even cartons. An ergonomic compact design combined with a quick three-minute changeover make the case packer one of the most flexible machines available, Delkor says. The machine’s patented intelligent synchronization technology allows for effective loading of nearly any product into cases, trays, retail-ready packages and brown-box shippers.

800-328-5558; www.delkorsystems.com/

FLEXIBLE PACKAGING LABELERS

EPI says it has been designing labelers for flexible packaging for over 35 years. The EPI Flex Pac applies pressure-sensitive labels to virtually any surface of the package or product, making it ideal for reclosable, promotional or primary labels. The company’s strong partnerships with the vast majority of bagger/wrapper manufacturers ensure it is providing new, innovative and integrated labeling solutions. EPI takes the time to understand manufacturers’ equipment, applications and operations. The EPI Flex-Pac family easily integrates with a variety of packaging machines, including vertical form-fill-seal, pouch, horizontal form-fill-seal and stretch wrappers.

800-755-8344; www.epilabelers.com

VALVE WITH IMPROVED PERFORMANCE

Festo says it packaged a mix of products with live product demonstrations at Pack Expo Connects. The presentation on the unexpected benefits of complying with food safety regulations was a highlight. The MPA-C IP69K washdown valve manifold and similar components designed for food and beverage applications were cited as being able to boost energy savings and improve machine performance. For example, no control cabinet is required for the MPA-C, allowing for faster installation and easier maintenance access. Additionally, shorter tubing, because the terminal is located nearer to actuators, improves cycle rates. The presenter said that if tubing length is reduced from 15 feet to 3 feet, cycle time becomes 50% faster.

800-993-3786, www.festo.com/us.

INTELLIGENT CHECKWEIGHERS

Designed for new-generation manufacturers embracing the digital revolution, Fortress Technology’s Raptor checkweighers include an intelligent conveyor removal system and intuitive digital process-monitoring technology to advance inspection efficiency, target operational inefficiencies and slash product giveaway. The Raptor launch range comprises three systems — a single-frame standalone checkweigher, a compact 1.7-meter combination metal detector and checkweigher, and an extra-large case-weighing system for bigger applications. Innovative common features across the range include no-tool maintenance, digital software processing and a unique conveyor motor release. The Raptor’s accuracy of data capture and analytics is another Fortress breakthrough, the company says.

416-754-2898; www.fortresstechnology.com/

ANNULAR SPACE HEAT EXCHANGERS

Annular space heat exchangers such as HRS Heat Exchangers’ AS Series pass the product through the gap between the inner and outer tubes, making them suitable for highly viscous products such as purees and thick sauces while ensuring even heat transfer. HRS says its corrugated tube technology increases heat transfer and energy efficiency, as well as reduces product fouling on the tube surfaces. HRS produces both a three- and four-tube version of the AS Series (the AS 3 and AS 4) to facilitate different arrangements and couplings of service fluid.

770-726-540; www.hrs-heatexchangers.com/us/

CUSTOMIZABLE PACKAGING MACHINE

Matrix says its Elete packaging machine is an ideal solution for customers looking for a high-performance, completely configurable solution. Its rugged design provides outstanding repeatability, and it can deliver tremendous value with automatic film tracking, a stainless-steel frame and numerous customizable options. It is available in standard or hygienic models and can produce several different bag sizes and multiple package styles such as pillow, gusset and flat bottom. The Elete can produce bags at up to 100 bags per minute, based on application. With several machine versions available, companies can choose the one that makes the most sense for their packaging application needs.

262-268-8300; www.MatrixPM.com

CONVEYOR VIDEO DEMOS

Multi-Conveyor says it provided education for its customers to make an informed conveyor purchase decision at Pack Expo Connects. Eight product demos focused on accumulation; product turning; hand-pack or semi-automated assists; merge, sort, divert and combining conveyors; building conveyors to sanitary agency compliance; conveyor-to-OEM line communications; affordable 24/7 workhorse conveyors; and dispelling the myth of expensive custom solutions. Multi-Conveyor says its goal is to provide or engineer a more functional, affordable conveyor while maximizing productivity or saving essential floor space. No project is too big or too small. Recorded demos can be found at www.pe.show/198.

800-236-7960; www.multi-conveyor.com/multi-media-center/videos

ROBOTIC CASE PACKER

Quest Industrial showcased its Quik Pick high-speed robotic case packer at Pack Expo Connects. A main differentiating point of the case packer is its speed and flexibility. With the QPick custom case-packing software, the Quik Pick can be configured to pick up as many as 1,000 pieces per minute. The Quik Pick works extremely well with flexible film packaging, thanks to its vision system and optional 3D scanning that quickly detects the pouches’ topography to identify the proper point for picking. While the ideal application is flexible film packaging, it performs well with just about any packaging type that comes from a vertical form-fill-seal or a horizontal flow wrapper machine, Quest Industrial says.

608-667-1416; www.questindustrial.com/

CUP FILLING AND SEALING EQUIPMENT

At Pack Expo Connects, R.A Jones says it showcased a wide range of cup filling and sealing equipment with the flexibility to fill/seal/over-cap straight and tapered walled cups and tubs. The demonstration dove into the company’s portfolio of cup technology for a variety of dry and viscous products across multiple industries. The company also focused on the features and benefits of its new Autoprod CF-400 cup filling/sealing system, including its extended frame with room for two fillers, pulsed light cup and lid sterilization, cup and lid vision inspection system, patent-pending sealed rotary drive mechanisms, and diving nozzles to reduce splashing and peaking with tracking to increase index rate.

800-216-4499; www.rajones.com

DENSE-PHASE CONVEY SYSTEM

According to Schenck Process, E-finity is a patented continuous dense-phase convey system for fragile materials. Precise pressure monitoring and airflow corrections allow the system to operate efficiently under all conditions, while gently inducing materials through the convey line in slug form. E-finity is ideally suited for granular and pelleted materials. Unique E-finity air controls can employ a single air source to operate two to three different systems simultaneously. The result is significant cost savings in both equipment and installation.

800-821-2476; www.schenckprocess.com/us

VIRTUAL TOURS AND DEMOS

Schubert says it presented a wide range of new features during Pack Expo Connects. By showcasing six different live demos, the company addressed current market challenges and requirements. Show attendees were offered virtual tours through Schubert’s headquarters in Germany and through its North American training center in Charlotte, N.C., and learned how to 3D-print parts on-site with Schubert’s PartBox. Schubert also put its employees in the spotlight. Aaron Beaulieu, a service technician for Schubert, showed how Schubert empowers its customers with training and transparency. He also explained what Schubert service jobs and machine installations look like and how operators can easily work on any Schubert machine system after the basic training.

980-244-3171; www.schubert.group

EASY-OPEN, RESEALABLE PACKAGING SOLUTIONS

Sealstrip Corp.’s easy-open and resealable solutions for cheese packaging provide enhanced consumer experiences and operational confidence while keeping costs down. The company’s applicators retrofit to current vertical form-fill-seal or flow wrapper, require no extra film and guarantee no reduction in line speed. Sealstrip’s FDA-compliant convenience features keep products fresher longer, maintain barrier properties and provide product protection and tamper evidence. The company says it also excels in developing custom features and systems to meet customers' diverse needs in an ever-changing market.

888-658-7997; www.sealstrip.com

EQUIPMENT DEMOS

To ensure that customers did not miss out on the latest news and innovations in the world of foreign object detection and sorting technology, Sesotec says is participated in Pack Expo Connects. The highlights included showcasing THiNK — a metal-detection system equipped with artificial intelligence — and NEXWEY — a brand-new checkweigher. Sesotec also hosted two live demos at Pack Expo Connects, both of which are available as recordings: “THiNK — Metal Detection with Artificial Intelligence” and “RAYCON D+ — Intelligent X-ray Inspection.”

224-208-1900; www.Pe.show/529

STAINLESS-STEEL FLOORING

SlipNOT's slip-resistant stainless-steel flooring products are registered by NSF International, are chemical- and corrosion-resistant, and provide a hygienic solution for slippery areas. Additionally, they can withstand the extreme cold of cryogenics and the heat of cookers and steamers, as well as daily washdowns and caustic cleaning agents. SlipNOT stainless steel can be applied to practically any stainless-steel surface. Customers may send in their own materials to be coated, or SlipNOT can supply custom-fabricated products to job specifications. SlipNOT says its products can be easily installed in new facilities or retrofitted into existing structures where slip resistance is required.

313-923-0400; www.slipnot.com

LEAK-DETECTION TECHNOLOGY

Designed for products ranging from small single-serve yogurt drinks to gallon-size milk jugs, the dual-sensor compression system from Teledyne Taptone is both versatile and sensitive, capable of detecting leaks as small as 0.006 inch in the headspace of the container at production line speeds up to 1.52 meters per second (300 feet per minute). The sensor design incorporates the company’s patented dual-sensor technology and high-speed compression belts for improved accuracy and container handling. The system was designed for harsh environments. Optional sensors expand the capability of the system to include additional inspections (fill level, cap, label), as well as testing for foil or film-sealed containers, Teledyne Taptone says.

508-563-1000; www.taptone.com

MULTI-POINT DEPOSITOR

Yamato says companies can reduce labor, risk and overfill with its multi-point depositor (MPD). The MPD works in tandem with a Yamato combination scale to automatically deposit precision-weighed products such as cheese into rigid or semi-rigid containers of all shapes and sizes. This high-sanitary solution also helps improve food safety. Visit Yamato’s Pack Expo Connects virtual showroom for on-demand viewing of the demo “Yamato Weighs In: Filling Rigid & Semi-Rigid Trays” to learn even more about this equipment and the ways it can improve companies’ business operations.

262-236-0000; www.PE.show/330