“We survived the first without shutdown,” says Todd Rutter, president of the York, Pa.-based fluid processor, a unit of the family-owned Rutter’s Holdings Inc. “But after two 20-inch blizzards in five days, we shut down, basically because the county shut down the roads.”

Luckily for the Rutter’s team, the flurries that were falling across York County in southeastern Pennsylvania were all the snow that would come that day, as the latest nor’easter swung out over the Atlantic, wreaking more havoc to the north and east.

But just a few weeks earlier, Rutter’s Dairy had to contend with massive snowfall and a spike in demand for its milk and beverages – sold at regional and national retailers, as well as the company’s chain of convenience stores – as folks stocked up in advance of being snowed in.

“Major roads had 10- to 15-foot drifts,” Rutter says, explaining how sustained 40 mph wind gusts made conditions perilous for the dairy’s delivery trucks. “They’d be opened and then three hours later be blown shut again.”

The company put up its employees in a nearby hotel to keep them safe and bottled milk as fast as it could. “As fast as we got milk off the farms, we got milk to shelves and refrigerators, probably the same day,” Rutter says.

As the weather cleared, Rutter’s Dairy emerged without injury or damage. But then, one would expect nothing less from a company that has weathered many a storm, meteorological or otherwise, throughout its long history, which dates back before the American Revolution.

It’s a cautious way of doing business that’s getting Rutter’s through the current economic downturn in decent shape. The company is reaping the benefits of policies put into action back in 2007, when soaring diesel prices were blowing the lid off fuel budgets nationwide. But while other companies were enacting fuel surcharges to counteract the higher prices, the Rutter’s team decided there was a better, long-term way to offset the costs. (The company declines to divulge exact sales figures for its dairy operation; Central Penn Business Journal reports 2009 total revenue for Rutter’s Holdings of $500 million.)

“We looked at the profitability of all our accounts,” explains Tom Johnson, manager of the sales team, “and ended up eliminating several accounts.”

This allowed the company to divest itself of marginal accounts that became barely profitable, if at all, because of soaring transportation costs.

“Five-dollar diesel was very detrimental to us,” Rutter says. “Others tacked on fuel surcharges; that’s just a stop-gap. So I forced our team to come up with a plan to not only get us through the high fuel prices, but to make us a better company for the long term. By encouraging some 220 accounts to buy from our competitors, we were able to consolidate routes, take trucks off the road and save a lot of fuel.”

Accounting Manager Lisa Grim adds: “The efficiencies and savings in the warehouse and administrative side were all just icing on the cake.”

Now, distribution supervisors Joel Workinger and Smoke Dehoff track all delivery routes monthly for quantity of goods delivered per gallon of fuel burned, mile driven and labor hours used, Rutter notes. “Five-dollar diesel makes distribution your number-one cost center and you can no longer afford to just assume moving volume through your plant covers that cost,” he says, noting that in the three years since, the plant has significantly increased its volume even with fewer trucks on the road through more strategic deliveries. “Before we take on a new customer, we do a thorough delivery cost analysis to determine if and where that customer might fit on a route and is that answer good for us.”

Diane Quinn, customer service manager, says the whole process is in constant motion. “It has kind of taken on a life of its own,” she says, “and all departments are contributing to its success.”

Still, the idea of dropping accounts is foreign to most in the sales realm. “I try to explain the theory and rationale of what we did and are doing to people in the industry, and they look at me like I’m from Mars,” Rutter quips. “It was not without great anxiety in the sales department. It was a huge internal cultural change for us. … [but] in today’s world the need to control costs overrides the desire to grow the business at an uncalculated pace. You can’t change the results you are getting to what you want to get, if you don’t change how you operate your business. It’s not the same industry it was five years ago, let alone 20 years ago..”

Now fuel prices are back to normal, he says, but “companies that just did fuel surcharges are no more efficient than they were before, while Rutter’s continues to enjoy the fruits of its efforts.”

Being in a comfortable position financially makes Rutter’s more able to handle another necessary evil coming in the next year: an anticipated 40% spike in electricity costs following the expiration of a 10-year state-instituted rate freeze.

“We’re going to try to negate as much of that increase as we can through reduced consumption,” says Operations Manager Brett Garner, explaining the company will focus on its “energy hogs” like motors, compressors and light bulbs, and pursue more energy-efficient options. “With better electronics and computer controls, we can start operating in a more effective way.”

What's in store

That’s why it’s important for Rutter’s Dairy to leverage any advantage it has to doing business better, including the synergies derived through the company’s c-store chain.“They started as a guaranteed customer for our milk,” Rutter says of the stores, now numbering nearly 60 in six Pennsylvania counties, the first of which opened in the late 1960s. “We think we’re good at leveraging each other’s special talents.”

The dairy acts as a logistics resource and a distributor for other products sold at the stores besides milk and beverages. Also, the dairy has access to the chain’s market research to guide product launches, as well as technologies. “We piggyback on their technology platforms that we couldn’t support or afford without them,” Rutter says, noting that the dairy’s and store chain’s separate corporate offices each have backup computer servers for the other. Plus, Rutter says, “We have one of the most sophisticated Web-based customer compliment/complaint systems I’ve seen.”

Rutter’s Farm Stores are visited by a half-million customers a week. “We operate separately but cross-market and cross-leverage as best as we can,” Rutter says. “We are their image and they are ours.”

As such, the company keeps its leased truck fleet up to date and looking brand-spanking new. The oldest truck is 6 years old; the company recently redid most of the fleet’s graphics.

The company also takes advantage of its heritage at a time when locally sourced food is considered a plus. “We’ve been a dairy since 1921 but on this farm since 1747. We were fresh and local before that was hip. Our stores’ marketing campaigns leverage that,” Rutter says. “Most of our marketing is based on things people see and file away until they’re ready to make their purchase.”

But Rutter’s products can be found outside its own stores, at other outlets throughout the northeast. “We do a lot of c-stores, a lot of supermarkets, national chains,” Rutter says. “We don’t have our own stores in Maryland, so that business is independent.”

Tea time

And despite being a dairy, quite a lot of product carrying the Rutter’s brand is something other than milk – juices, waters, punches, but mostly tea. After all, this is southeastern Pennsylvania, where RTD tea is almost a religion.“It’s hard for people in Chicago or Texas to understand how important tea is here. I’ve had tea suppliers tell me 90% of what they sell is into this market,” Rutter says. “We’ve been selling tea since 1940. This area has had ready-to-drink tea long before Snapple and Lipton.”

True, more dairy processors have been filling out line time with non-dairy beverages, a move that has proven lucrative. But here in iced tea country, it’s more than the money – it’s a consumer base with a voracious thirst. The folks at Rutter’s speculate that their market’s love of tea dates back to a time when dairies were far greater in number and they needed something in their product lines to set themselves apart from the competition.

“In this area, we had so many dairies competing with each other, you needed something different as a bargaining tool,” says sales representative Rick Miller. “Tea was an incentive for a customer to take on a dairy’s entire line.”

Interestingly, tea country is a tight market; travel 90 minutes south to Baltimore and it’s a hard sell.

“I’m trying to grow that market,” says sales rep William Bolden, explaining that Rutter’s promotes sampling events in an effort to make inroads south of the Mason-Dixon Line. “With Maryland being a southern state, you’d think that they’d gravitate toward tea. I don’t know if it’s because they go with a national brand or there’s just no desire yet.”

Recognizing that the South is a stronghold for home-brewed sweet tea, Rutter’s recently launched Southern Brew, in regular and diet (artificially sweetened) varieties. “It’s made to emulate homemade Southern-style sweet-brewed tea,” Rutter says.

Speaking of brewed, how does that compare to a product like Rutter’s, which derives its teas from a powdered mix?

“People who brew tea at home, that’s a hard flavor profile to match,” Rutter says, noting that everyone who home-brews does it to their specific taste for strength and sweetness. “We’ve tinkered with it.”

The company’s biggest seller is its original tea (sweetened, with lemon). But that’s just the cusp of a line that encompasses 14 flavors and 40 SKUs. “We work with flavor houses. We give them an idea of what we want and they come back with samples,” Rutter says. “We don’t specifically go out and get opinions on flavor development. We’ll usually take a known success and go with that.”

Miller adds: “We also look at other beverage types and wonder how they would translate for tea,” for example, Rutter’s orange-flavored iced tea.

“We’re always looking to launch new flavors,” sales rep Mike Mummert says. “We’re cautious of having too many at one time because of the store’s shelf space issues. So we try to be very conscious of making sure it’s a proven flavor.”

Of course, Rutter’s Dairy is at its heart a dairy, and milk is still the line leader. Most of the year, the output is 70% milk to 30% tea.

“In summer, it will swing to 60/40, or if it’s really hot, 50/50,” Rutter says. “When it gets over 90 outside, tea sales kick in like milk sales do before a snowstorm.”

Rock solid

Meanwhile, Rutter’s Dairy honors its heritage and reaches out to the community by hosting 2,500 grade-schoolers every year for tours of the farm and milk plant that demonstrates, as Rutter says, “how much effort it takes to get food from farm to table.”The tours have been a York County tradition for half a century. In fact, multiple generations of family members remember coming as kids and then again with their own children and grandchildren. Visitors can observe the bottling lines through the glass wall of the “tour room” that overlooks the plant floor.

Rutter’s was still producing some of its own milk up until just six years ago, Rutter notes. “We’re still a working farm with a small herd of heifers; we’re just not milk-producing,” he says. “But we’ve been a working farm since 1747.” Now, the company sources most of its milk – all from cows not treated with rBST – from independent farms within 100 miles of the plant.

Its past and present secure, Rutter’s Dairy is looking cautiously to the future.

“We’re preparing for the worst and hoping for the best,” Rutter says. “We’re not doing anything to put us in a risky position. We’re rock solid now and we want to stay that way. We have ambitious expansion plans, but we’re in a holding pattern until these economic and banking crises straighten themselves out.

“We continue to grow but within the confines of our facility, by making what we have more efficient. We think that is the best conservative strategy to get us through this mess.”

History

Rutter’s Dairy traces its roots to 1747, when William Penn’s grandson deeded farmland (on a sheepskin the family still has) in York County, Pa., to the Rutter family. Brothers George and Bud Rutter grew up on the family homestead. They sold their farm products – on their first day in 1921, eight quarts of milk from a horse-drawn wagon – to the public and were the sole employees in the early days.By 1946, 12,000 quarts of milk were produced each day. The 1940s also saw the first member of the second generation of Rutters join the company.

Rutter’s Dairy is the lone fluid dairy left in York County, spending more than $15 million annually to purchase milk from area farms. Rutter’s Dairy serves Pennsylvania, Maryland, Delaware and New Jersey.

To counter competition from supermarkets that owned dairies, Rutter’s Farm Stores debuted in 1967 as an additional outlet for Rutter’s Dairy products. The first company convenience store opened in York in February 1968; two more opened later that same year.

Today, Rutter’s Farm Stores has more than 55 stores in York, Lancaster, Adams, Cumberland, Dauphin and Franklin counties. In addition to Rutter’s Dairy products, stores now offer fast food, ATMs and pay-at-the-pump gasoline.

With its growth, Rutter’s also developed a unique corporate style: All decisions are made by consensus of the management team; there is no CEO.

In 2005, Rutter’s Holdings Inc. was formed as a parent company for the three operating companies. Three cousins each serve as president of a different Rutter’s company: Scott Hartman at Rutter’s Farm Stores, Todd Rutter at Rutter’s Dairy and Tim Rutter at M&G Realty, a real estate holding company.

Rutter’s remains a family owned and operated group of companies. Current estimates indicate that the group returns approximately $70 million yearly to Pennsylvania’s economy.

Rutter’s annual fund-raising efforts contribute more than $75,000 to local organizations and charities. Rutter’s 2009 charitable gifts, most of them to aid children’s causes, have pushed its community giving to more than $2 million over the past seven years.

“Children are the future of our companies, and they’re truly the future of this country,” says Todd Rutter, president of Rutter’s Dairy. “It’s an honor for the Rutter’s companies to support non-profit groups and programs that do so much to improve the lives of children in our community.”

SOURCE:www.rutters.com

The Rutter's Family of Products

Rutter’s Dairy offers a full line of dairy food products, including milk – produced by 135 area dairy farmers – in various container sizes. Milk varieties include whole, 2%, 1%, skim, chocolate, fortified skim milk (with extra skim milk solids), acidophilus, lactose-free and buttermilk.Rutter’s branded cultured products include dips, sour cream, cottage cheese and yogurt.

Butter, margarine and creamers round out the dairy offerings.

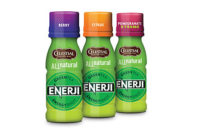

Highly popular are Rutter’s cold-drink offerings, especially its ready-to-drink iced teas, offered in 14 flavor variations, most in regular or diet. In addition to the best-selling original (sweetened lemon), tea varieties include Green Tea, Southern Brew, Peach, Orange and Mint Green. Other drinks

include lemonade, orange drink,

fruit punch, waters and orange juice.