Alfa Laval introducesthe TS6 plate heat exchanger, which offers a more efficient solution to this water heating process over former shell and tube HE technology. The key TS advantages over shell and tubes are flexibility, small footprint, quick response time, and expandability/serviceability. The small footprint can reduce hot water set package size by over 50%, reducing skid costs and saving valuable plant floor space.

Alfa Laval Inc.

262/605-2617

www.alfalaval.com

carl.lemke@alfalaval.com

Feldmeier

Feldmeier Equipment Inc.

315/454-8608

Bimetalix

Bimetalix

262/593-8066

www.bimetalix.com

Waukesha Cherry-Burrell says its homogenizer isamong the most efficient in the industry, and offers the smallest footprint, delivering more output for its plant space than any other. Advanced, fluid-dynamically engineered homogenizing valves achieve the desired degree of dispersion/emulsion with lower pressures, requiring less energy and extending the life of moving parts. Features include a sanitary overpressure relief device; non-adjustable plunger seal with double seals standard (single seals optional); modular valve assemblies (single or double stage, manual or hydraulic); headblocks with hardened replaceable valve seats; and multiple plunger sizes for each model.

Waukesha Cherry-Burrell

800/252-5200

www.spspe.com

Tetra Pak

Tetra Pak Inc.

800/806-9675

www.tetrapakprocessing.com

processing.na@tetrapak.com

The Tetra Alex line of homogenizers from Tetra Pak offercapacities from 15 gph to 12,100 gph for beverage and dairy products. They operate at pressures of up to to 5,800 psi, and utilize fully reversible seats and forcers which further improves the operational economy. An easily accessible machine casing means less time is needed for routine maintenance, and valves, seats, and pistons are removable with hand tools. HD100 homogenizing device is designed to maximize efficiency and parts lifetimes. The machines also operate at low sound level, and are totally enclosed for safe operation.

Tetra Pak Processing

847/955-6339

David.Rudolph@tetrapak.com

www.tetrapakprocessing.com

AGC Engineering’s Sanitary Proflow Series of plate heat exchangers arespecifically designed for dairy applications. Features include an expanded port area, inlet design, metal-to-metal alignment and fully drained leak detect to improve flow and performance characteristics. The Proflow plate design allows processing of heavy viscosity products at high production flow rates without the damaging effects of high pressure. Different frames are available including tie-bolt, twin spindle manual closure and also hydraulic (automatic) closure.

AGC Engineering

800/715-8820 or 800/825-8820

www.AGCEngineering.com

Admix

Admix Inc.

800/466-2369

www.admix.com

Chester-Jensen

Chester-Jensen Co.

800/685-3750

www.chester-jensen.com

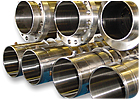

Scherping Systems in-line, single pass heat exchangers arecrafted using T304 stainless steel tube sheets, tubes, outer shells and reducing adapters. They are available in standard sizes or manufactured to meet your specific heat transfer capacity and space requiements. The heat exchangers include steam inlet, condensate outlet and vacuum break connections as required. Scherping Systems stocked, standard CIP heat exchangers have concentric and eccentric reducing adapters, reducing solution inlet and outlet ports with required tri-clamp connections. The reducing adapters assure proper drainage of horizontally mounted units.

Tetra Pak CPS

320/485-4401

The Twin Panda homogenizer is a tabletop homogenizerfrom Niro Soavi designed for laboratory/pilot use. The Twin Panda is designed to homogenize samples at pressures up to 8,700 psi. The internal design has special features permitting the homogenizer to handle feeds at high viscosity up to 20,000 cP and at temperatures up to 90°C (194°F) without a feeding pump. The Twin Panda 600 homogenizer is easy to commission and operate. It can easily be dismantled for maintenance and cleaning by the laboratory operator. Homogenization conditions can be optimized and the results used in scale-up to industrial operations.

Niro Soavi NA

603/606-4060

www.nirosoavi.com

The Mueller Accu-Therm plate heat exchanger isa compact heat exchanger consisting of embossed heat transfer plates with perimeter gaskets to contain pressure and control the flow of each medium. The gasketed plates are assembled in a pack, mounted on upper and lower guide rails, and compressed between two end frames with compression bolts.

Paul Mueller Co.

800/MUELLER (683-5537)

www.muel.com

Waukesha Cherry-Burrell

Waukesha Cherry-Burrell

800/252-5200

www.spxpe.com

APV

APV/Invensys

800/544-5290

www.apv.com

answers.us@apv.com