Since its founding in 1933, Whitey’s Ice Cream has been bringing “a lick of joy and fun” to thousands of customers in the Quad Cities area (Rock Island and Moline in Illinois and Davenport and Bettendorf in Iowa). Celebrating its 90th anniversary in May, the ice cream purveyor grew from a one-store business at 16th Street and 23rd Avenue in Moline, to a total of eight stores in Illinois and Iowa all reliant on a 25,000-square-foot manufacturing plant to keep up with eclipsing demand for Whitey’s creamy cones, upside-down milkshakes, award-winning Chipper ice cream sandwiches and more.

Named “Best in the Midwest” by Midwest Living magazine, Whitey’s Ice Cream produces nearly 100,000 3-gallon tubs in 50 flavors, 400,000 1.5-quart containers, and 500,000 gallons of ice cream in a small but mighty plant located at 2525 41st St. The headquarters, a stone’s throw away from its flagship shop at 2601 41st St., contains offices, a four-bay loading dock and coming later this year, two Superior DF 1500 Continuous Freezers, with the capacity to continuously freeze 400 gallons per hour each.

Identical twins Mike and Mark Cutkomp, co-plant managers at Whitey’s, have been with the ice cream manufacturer for 25 years, starting in the business together when they were just 22 years old.

— Mike Cutkomp, Co-plant manager, Whitey’s Ice Cream

Growing up in Milan, Ill., (population 6,000), about 9 miles northeast of Moline, the brothers had no idea when they initially applied that Whitey’s made its ice cream onsite. “We thought that the ice cream was brought in,” Mike Cutkomp notes. “It was interesting to find out that some of the best ice cream in the Midwest was being made in our backyard.”

Mark Cutkomp adds: “I can tell you that every job we’ve ever had, we’ve worked together, and when we saw the ad in the newspaper, we interviewed with Gary [Neer], the plant manager at the time, who took a shot on us.”

Now married with children of their own, Mike and Mark arrive at the plant at 4 a.m. each weekday morning with the first job being to sanitize all of the machines, including tanks, freezers, the ingredient fillers, and half-gallon machines.

“At 5 a.m., our guys come in and we build pallets with the cartons and products made the previous day. Mike then ‘flavors up’ the tanks of mix and we’ll start the freezing process,” Mark explains. “After the freezing process, we start filling 1.5 gallons, pints, and 3 gallon tubs and run for about 6 hours, then we take everything apart, clean and wash everything, and put it all back together again, which takes about 2 hours. Our goal is to make sure we have a two-week supply of ice cream from each run.”

With the amount of potential allergens, extra care is undertaken to prevent cross-contamination, they note. For example, most ice creams with nuts such as Black Walnut, White Chocolate Raspberry, and Praline Pecan are processed on one day, while for example, the “eggier” ice cream made with egg yolks, including French Vanilla, Lemon Custard, and Key Lime Pie are made on a separate day.

Legally, ice cream must contain at least 10% butterfat otherwise it’s considered reduced fat and Whitey’s handmade ice cream recipes contain 12% butterfat.

When scanning a Whitey’s Ice Cream label, Grade A Milk, Cream, and Sugar are the first three ingredients.

On the day that Dairy Foods visited, equipment was churning out 700 gallons of Shake Base, the pure shake base shipped to Whitey’s ice cream shops that are then flavored with toppings like vanilla, chocolate, strawberries — the company goes through 10,000 quarts of strawberry flavoring annually — Oreos, Reese’s Peanut Butter Cups, Cookie Dough pieces, and many more.

Whitey's Ice Cream

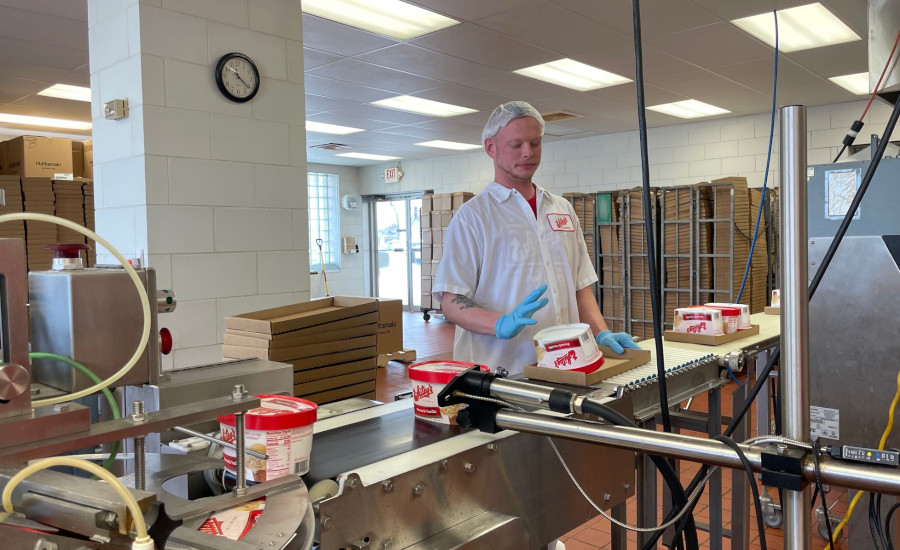

Employed at Whitey’s for one year, Jeff Hoover works the production line churning out cartons of French Vanilla ice cream. Whitey’s produces about 40,000 1.5 quarts of French Vanilla annually. Whitey’s large 50-by-60-foot freezer hold 52 pallets of 1.5 quart containers, 3 pallets of Chippers, 12 pallets of Mini Shakes and 4,000 3-gallon tubs of ice cream. The five top-selling flavors in 1.5 quarts are Vanilla, Moose Tracks, French Vanilla, Chocolate Chip Cookie Dough and Mint Chocolate Chip, while the top flavors products in 3-gallon containers for in-store customer enjoyment are Vanilla, Graham Central Station, Mint Chocolate Chip, Chocolate and Cotton Candy.

“So, today we processed 1,500 gallons; 400 gallons of Vanilla, 700 gallons of shake base, and 400 gallons of French Vanilla,” Mike Cutkomp says. “It’s staggering because there’s very little automation, honestly — around 25% — that is driving plant operations.

“The 1.5 gallon machine is the only part of the production line that is fully automated along with the mini-shake machine that fills itself,” he continues. “We pull pints, gallons, and three galloons by hand and the machines are able to process 600 gallons an hour on two production lines and one packaging line.”

Overcoming challenges

Making ice cream the Whitey’s way, keeping the product consistent — not too soft and not too stiff — is among the biggest hurdles. “The machine filling has to be consistent too, but once you get the right fill, you don’t have touch it again,” Mark explains. “Another big challenge is supply chain issues. Every single ingredient coming into this building from outside sources has been impacted by COVID.

“It went from one week to get something to three weeks,” he continues. “And with prices to make ice cream including mix, eggs, chocolate, etc., going up along with everything else, we have to take a hard look at what flavors are most popular and which flavors we might want to make less of.”

Regardless of cost, a commitment to quality has been synonymous with Whitey’s for 90 years, with demand for its famous upside-down shakes, ice cream cones, regular and specialty sundaes, slushes, and smoothies beloved by legions of fans in the Midwest and beyond.

While Whitey’s is hesitant to share its annual revenue, Co-CEOs Jeff and Jon Tunberg state that sales were up 4% in 2022 and they’re optimistic for continued growth in the company’s ninth decade. “We’re fortunate that demand has not wavered for the goodness of our ice cream,” Jon Tunberg states.

Keeping the equipment humming along also can present challenges, particularly as the ice cream freezers that have been making Whitey’s ice cream date back to the 1950s, according to Mark Cutkomp.

“When I started here 25 years ago, the plant pretty much runs like it does now,” he explains. “We’re thankful that our freezers have held out for as long as they have and they’re kept at a cool -32 degrees Fahrenheit. The story goes that Hershey’s was auctioning off some of the same freezers, so we bought eight of them because the parts are hard to find. Luckily, we’re getting new state-of-the-art freezers to help with increased volume demands.”

On the day Dairy Foods visited, Jeff Tunberg shared that he had just gotten off the phone with a banker about financing two new high-tech ice cream freezers — Superior DF1500 Continuous Freezers that can churn out 400 gallons of ice cream an hour.

“Right now we’re using 1950s vintage Cherry Burrell ice cream freezers with a capacity of 300 gallons each,” Jeff explains. “When we started in the business, we had a 10-gallon batch freezer that also was a Cherry Burrell. We’re planning for the future with this $300,000 investment that is scheduled to arrive later this year. This will enable us to boost production by roughly 20%.”

Going the extra mile

Whitey’s Ice Cream prides itself on delivering the “Best in the Midwest” when customers are looking for some indulgent ice cream to enjoy at their ice cream shops, to pick up at their local Jewel or Hy-Vees, or when ordering through eCommerce on the company’s website (www.whiteysicecream.com).

“Last year, we made 230,000 gallons of ice cream mix. We also make 16 different flavors to add to shakes in-house, used approximately 82,000 individual Reese’s Peanut Butter Cups, and purchased 22,000 pounds of Oreos for our Cookies Galore and White Tiger Paws, to name a few,” Mike Cutkomp says. “Three varieties of cookies for our Chippers are homemade and baked in our little oven downstairs. We always go that extra mile to make sure our customers enjoy the freshest, best-tasting frozen treats.”

That means not skimping on the quality of the ingredients. For instance, Whitey’s Vanilla, Jeff’s favorite flavor, for its “simplistic pureness,” and French Vanilla use pure vanilla extract as opposed to half pure vanilla and artificial vanillin, which is the primary component of the extract of the vanilla bean, Tunberg explains.

“If you can’t make good Vanilla Ice Cream, you can’t make good ice cream. Period. If you want your carton of Vanilla to say Vanilla Ice Cream, you are required by law to use pure vanilla extract and that is what our cartons at Whitey’s say. We use an exclusive pure Madagascar vanilla bean extract made specifically for us,” Jeff Tunberg emphasizes. “If you don’t mind if it says ‘vanilla flavored ice cream,’ then you can use half pure and half artificial vanillin. If you don’t mind if it says ‘artificially flavored ice cream,’ than you can use all artificial ingredients, which costs 10% of real vanilla and you don’t have to use as much. That’s the choices you make in the manufacturing process. We don’t make ‘sweet and cheap’ ice cream.”

Mark Cutkomp notes that the operations and manufacturing of Whitey’s Ice Cream hasn’t changed that much, even though its producing around 50 flavors a year at a plant that seems small when compared to the 500,000 gallons its making yearly.

“We’re not fully automated yet, but we have great people around us who make this all possible. We don’t need a larger plant because we still have plenty of space to add another production line,” he concludes. “Honestly, it doesn’t take a lot of room to make ice cream, it takes a lot of room to store ice cream. The new high-tech freezers coming in October are going to be game-changers. It’s just a great present to celebrate our 90th year in business and to make sure we’re around for another 90 years.”