WASTEWATER TEST KITS

Clean Water Technology (CWT) says it offers free wastewater testing kits for review of dairy industry wastewater effluent values of total suspended solids, chemical oxygen demand and turbidity — then recommends the best treatment plan to cost-effectively achieve wastewater treatment goals. By coupling the testing kit with its wastewater survey, CWT can then design and install the entire wastewater treatment plant from sump pump to complete treatment with a process guarantee and equipment warranty. Order a free kit.

310-380-4648; https://cwt-global.com

CLAMPS AND VALVES

Dixon Sanitary introduced its newest product — the Clever Clamp. This innovative clamp offers consistent, controlled compression every time. The company’s patent-pending design eliminates the need for torque tools to get the proper gasket compression, helping prevent bacterial traps in process lines. Another of Dixon’s products that is ideal for the dairy industry is its SSV-Series single-seat valve. Machined from solid bar for added durability and reduced distortion caused by large temperature fluctuations, the valve is designed for easy actuator configuration and is 3-A certified for clean in place, Dixon Sanitary says. Contact sanitarysales@dixonvalve.com to learn more.

800-789-1718; www.dixonvalve.com

CUSTOM CHIP TECHNOLOGY

Everactive’s always-on, battery-less and wireless solutions are the easiest and most cost-effective way to continuously monitor industrial assets at scale. The solutions maximize returns via increased uptime, optimized maintenance and reduced energy consumption. Everactive’s custom chip technology delivers wireless and always-on sensing devices operating at power levels up to 1,000 times less than existing solutions. Such extreme energy-efficiency allows Everactive’s devices to power exclusively and continuously from tiny amounts of harvested energy, thereby eliminating the need for batteries. Everactive's products are deployed at leading American and global manufacturing facilities, the company says.

617-221-3050; www.everactive.com

VACUUM TECHNOLOGY SOLUTIONS

Leybold says it was fortunate to be a part of Process Expo 2021 in November. Its booth featured modern dry vacuum technology solutions, including selections from its Novadry, Screwline and Dryvac lineup. The food industry is evolving, and so is its stance on water consumption. There is potential for the dairy industry to benefit tremendously from switching from liquid ring vacuum technology to oil-free vacuum pumps. Leybold’s dry vacuum pump solutions can help the dairy industry with its efforts in reducing its carbon footprint, saving money and saving the environment.

800-764-5369; www.leybold.com/en

BELTED CHAMBER MACHINE

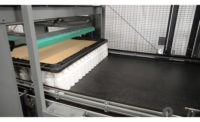

Multivac says its new B 625 belted chamber offers the best solution for automated vacuum packing in film pouches. As the fastest belted chamber machine available on the market, with speeds up to 3.5 cycles per minute, it’s built for speed. The chamber offers a hygienic design with an all stainless-steel build, patented tilting chamber lid and seamless design, making it easier to clean than similar machines on the market. The B 625 also has a low operating cost with fewer moving parts, valves, seal bars and cutting knives to service and replace compared to a rotary chamber.

800-800-8552; https://us.multivac.com/en/

UV-C DISINFECTING DEVICE

Nelson-Jameson says it offers the Aurora UV Disinfecting Device from SMS Technologies, which uses ultraviolet (UV-C) radiation to help deactivate most viruses and bacteria on surfaces in a short amount of time. Using the Aurora as part of your routine sanitation program helps keep your facility safe and protected from contamination. The lightweight, mobile design enables you to quickly and easily maneuver around most areas in your workplace — from production areas to office cubicles and everything in between. After a thorough cleaning, illuminate your surfaces with the powerful UV-C light to assist in breaking down microorganisms by hitting all of those hard-to-reach places.

800-826-8302; nelsonjameson.com

CLAMP-ON TEMPERATURE SENSOR

Omega Engineering says the high-accuracy Hani sensor attaches to piping systems in seconds without interrupting flow or production. Unlike invasive sensors, Hani sensors require zero contact with products such as ice cream and soups that might affect accuracy, reduce flow, clog pipes, and may lead to contaminant problems. Using Hani sensors removes obstacles to clean-in-place and product recovery systems so no sensors need to be removed before running pigging and cleaning cycles. Winner of the dairy category of the Innovations Showcase and the People’s Choice award at the 2021 Process Expo, Hani sensors mount outside and measure inside.

Visit www.omega.com/hani 888-826-6342

SOFTWARE FOR DAIRY PLANTS

ProLeiT supports its customers in the dairy industry in staying agile and safe in their task to fulfill varying market demands with outstanding quality. Its software can fit at different layers in the plant’s infrastructure, including bottom-line shop floor controls, efficiency tracking and seamless data integration with the commercial layer. The company says it sees a growing demand from dairies to implement dedicated functionality such as tracking and tracing, advanced recipe and batch control, or skid automation in a heterogeneous environment without having to completely replace the overall existing controls infrastructure. Within this, cybersecurity considerations are always among the top requirements.

224-880-6536; www.proleit.com