The Challenge: Dairy processors must protect the flavor from cow to consumer. Unfortunately, food scientists have not been able to develop a scientific test for evaluating flavor or detecting "off-flavors" in milk. Thus, the industry must rely on sensory or taste testing-the Ultimate Consumer Quality Test.

The delicate flavor/good taste that consumers expect starts with raw milk and must be protected during processing and distribution. If raw milk has an off-flavor the finished product will have an "off-flavor." Flavor defects cannot be removed, diluted out, or covered up by processing.

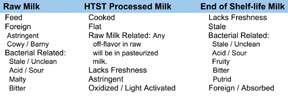

The most common flavors in raw, fresh HTST pasteurized, and end-of-shelf-life milk are:

A brief discussion of the causes and prevention of a few of the "off-flavors" listed above follows:

Feed: This is the most common flavor in milk. It is related to what the cows eat or smell two to four hours prior to milking. If it is mild and leaves a clean after taste-it is a normal flavor for milk and is not objectionable to consumers. Intense flavors caused by eating or smelling green chop, silage or being on pastures with weeds and certain green grasses two to four hours prior to milking will be objectionable. Control: Check the odor of tanker loads when the dome cover is opened. If unusual or strong odor is noted-laboratory pasteurize sample and taste before receiving.

Astringent: This flavor defect has become more prominent in recent years. It is identified as an after taste sensation that tends to "dry" the pallet or leave a "puckery" mouth-feel. The defect may be observed in raw and pasteurized milk and is caused by excessive use of teat dips, udder washes, sanitizers, cleaners, and acid rinses. At low intensities - product quality is compromised. At high intensities - consumer complaints will be encountered and market recalls/ withdrawals may be required. Control: Effective enforcement of SOP's and SSOP's at all points.

While dairy processors perform many tests to ensure the quality and safety of milk-the consumer performs only one Quality test-taste. Consumers expect milk to have a clean, fresh and delicate taste-even if the product is purchased on the "sell by" date. The dairy industry must become skilled in performing critical sensory taste tests to ensure that our products do not flunk the Ultimate Consumer Quality Test-TASTE.