The world population keeps increasing: In 2050, there will be nearly 10 billion mouths to feed. Our current animal food production system will not suffice.

Therefore, food producers, ingredient companies and researchers are on a quest to find sustainable alternatives. Enter plant proteins. Available in abundance, they are often a side or waste-stream of existing food production processes. Moreover, they can offer additional benefits such as muscle health support, improved digestion and weight control.

But while consumers are actively trying to eat more plant-based or animal-and-plant-protein blended foods (and reduce their meat consumption), they are not willing to compromise on taste and texture. Indeed, customers’ expectations are skyrocketing: They want something special, and they want it now. And it should be as transparent and sustainable as possible.

Bridging the gap

If we are to meet their expectations, we will need to bridge the gap between our understanding of animal-derived proteins and alternative ones such as plants, algae and insects. Microalgae, for instance, are known to be highly functional as foaming agents or emulsifiers. But how do we apply them without creating fishy and musty off-flavors, or green or red off-colors?

We could make use of insects. After all, they can quickly produce large amounts of protein-rich biomass and have the potential to convert low-value waste into higher-value insect proteins. But as long as the Western world struggles to accept their application in a visible form, we will need to grind them, leading to brown off-coloring and protein hydrolysis.

A success story of alternative proteins is presented by the extraction of RuBisCo, the world’s most abundant protein. NIZO scientists have been able to prevent off-color and solubility issues while upscaling and testing the process at a semi-industrial level.

Selecting proteins

When it comes to meeting customer demands in support health aspects such as weight control, it pays off to look into the satiety potentials of various proteins. Whey protein, for instance, hardly increases in viscosity in the stomach. It is also easily degraded; thus, readily available for consumption, making it ideal for rapid muscle recovery.

Casein, on the other hand, is broken down slowly and absorbed later, making it more ideal for long-term recovery. Pea protein takes a middle position, breaking down more quickly than casein, but slower than whey.

Solving taste and texture issues

Another issue we face is the deterioration of flavor and the decrease of solubility during extraction and processing. Increasing our understanding of their impact on the quality and functionality of proteins will enable us to adjust the production process and develop ingredients that deliver the optimal sensory perception.

It is worth noting that we don’t need new and expensive drying techniques to keep plant protein in its native state. By adapting critical conventional steps during extraction and spray drying, it is possible to maintain functional properties and tailor ingredients for specific applications.

Blending proteins

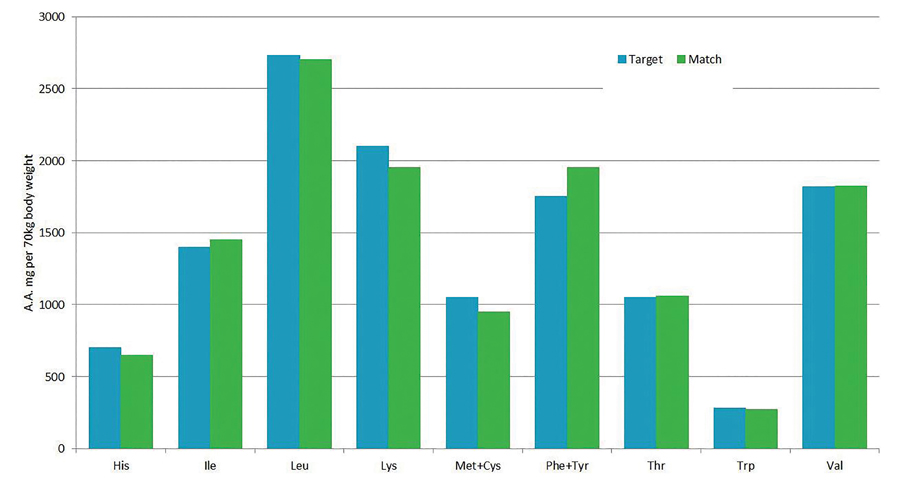

If we are to live up to customer expectations concerning nutritional benefits, we will need to look into protein blends. After all, many plant proteins require blending to provide a complete nutritional profile. There are various tools on the market that support the search for the right proteins to be blended (see the figure).

To tailor to customers who wish to experience new food sensations, we can use protein blends to develop food products with novel texture and sensory attributes.

Processing proteins

A final challenge to overcome has to do with the impact of product properties on processing conditions. For example, an important issue of spray drying is fouling of the dryer due to stickiness of the product. This is especially true for products with a high content of carbohydrates and proteins, such as infant formula.

Fouling results in shorter run times between cleaning procedures and, at worst, causes blocking of the dryer by lumps of powder. Improved process control by humidity measurements can minimize fouling, extend the time between clean-in-place procedures and avoid blockages.

Can we meet customer demand?

Can we meet customer expectations regarding flavor, texture, health and sustainability of plant-based products? The answer is yes. But there are challenges to overcome.

Most importantly, we will need to expand our understanding of plant, insect and microalgal proteins. In addition, we can develop products with new texture and sensory attributes, or ensure that replacement of animal protein does not compromise taste, texture and nutritional properties.

Either way, we will need to focus on the creation of synergizing protein blends and the optimization of extraction and processing methods. Although we still have ground to cover, if we continue our quest, we will be able to feed those 10 billion people in 2050 with healthy, sustainable and tasty foods.