The Tillamook County Creamery Assn., Tillamook, Ore., has moved to trademark the Tillamook name and require numerous other companies to remove the name from their products. Since Tillamook is the name of a county where the cheese and other products bearing the Tillamook name are produced, opponents say it is unfair to trademark the name of a place. But proponents say products such as Philadelphia Cream Cheese and Hershey's Candies have already set a precedent.

One of the dairy industry's best-known traditions is returning to its roots. After a five-year stay in California, the Marschall Cheese Seminar returns to Wisconsin this year. Rhodia Inc., Cranbury, N.J., sponsor of the seminar, will combine the Marschall Cheese Seminar with the Wisconsin Dairy Products Association's (WDPA) Annual Convention. The combined event, to be known as The Dairy Symposium, will be held June 27-29, 2004, at the House on the Rock Resort in Spring Green, Wis. The Marschall Cheese seminar, celebrating its 41st year, will expand its focus to include other dairy products as a result of its new relationship with WDPA, which is in its 31st year. For more information on the Dairy Symposium, call WDPA at 608/836-3336 or Rhodia at 574/264-2557.

In 2004, there will be major promotions for milk, cheese and 3-A-Day of Dairy throughout the year. For example, in January and February, the American Dairy Assn., partnered with General Mills Inc., Minneapolis, on the 2004 Bake-Off® Contest, the biggest, most trusted recipe contest in America. For the first time in the Bake-Off's 50-year heritage, the contest featured four cheese awards to recognize America's best cheese recipes. The $1 million grand prize and the new cheese awards generated shopper excitement and sales for participating products, including cheese.

Sidebar: Vitamin D-fortified Cheese

Vitamin D is important in bone health. Leading public health experts are getting concerned that the general population is not getting enough as a result of decreased consumption of milk and increased use of sunblock. (The body makes vitamin D when unprotected skin is exposed to sunlight.)Fortified milk is one of the few noteworthy food sources of vitamin D. Fortifying cheese with vitamin D would create an additional source for consumers.

Researchers at the Minnesota-South Dakota Dairy Foods Research Center, St. Paul, Minn., have successfully fortified pasteurized processed cheese with vitamin D3 (100 IU per serving). There was no loss of vitamin D3 during manufacture, and the vitamin was uniformly distributed. No loss of the vitamin occurred during storage over a nine-month period; however, there was about 25% loss when the cheese was heated in an oven. The vitamin D3 did not impart any off-flavors to the processed cheese, as determined by sensory analysis.

Ongoing studies assessing the bioavailability of vitamin D from fortified cheese will be valuable to help validate this approach of supplying vitamin D to consumers.

Sidebar: Direct Casein Measurement for Cheese

Contributed by Spencer LovetteMany cheesemakers manage moisture and maximize yield by controlling their

cheese milk casein-to-fat ratio based on a protein and fat measurement. The results, however, are not optimal because they estimate casein by multiplying the protein measurement by a periodically defined casein number. Silo-to-silo casein numbers vary too much to rely on this practice, so significant losses result. A casein measurement on each silo is essential to maximizing profit.

Cheesemakers usually use Van Slyke's formula to determine Cheddar cheese yield. The formula requires known values for casein, fat and solids. Cheesemakers translate this formula into a casein-to-fat ratio (C/F) for different cheese varieties. With the C/F at the correct level in the cheese vat, nearly all the fat combines with casein to make cheese. This yields the maximum amount of cheese for a given quantity of milk. Proper standardization control of this ratio is critical to a cheesemaking operation. In order to control these variables, the variables need to be officially and accurately measured.

Fat is measured in nearly every dairy processing plant, but few cheesemakers measure casein. Historically, the only reliable method for measuring casein has been the International Dairy Federation reference (IDF 29:1964) method based on wet chemistry, two Kjeldahl determinations and a precipitation step. This all takes about four hours and significant skill. Therefore, in most plants, casein levels are determined by a specified percentage factor (casein number). The problem is that casein as a percentage of protein varies significantly.

Why not just measure casein? Everyone agrees that if they could cost effectively measure casein, they would. The good news is a new instrumental method based on laser light scattering is available. The method measures casein's specific particle size, which is unique in milk.

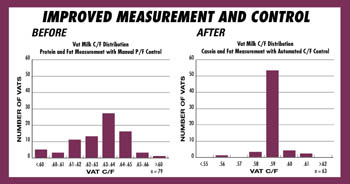

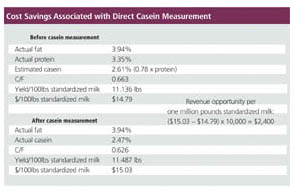

With a cost effective, rapid method now available for determining casein content, improved cheesemaking control can be obtained. For example, assuming accurate protein measurements and perfect protein-to-fat ratios, a 0.04 error in casein number translates to a 0.037 deviation in C/F. Eliminating this deviation with improved measurement and control of casein (as well as fat) provides additional revenue potential of $2,400 per million pounds of processed milk. (See table to left.)

The only way to achieve optimum C/F control is to measure casein with the same frequency as fat. Cheesemakers that take advantage of the opportunity to measure and control casein directly are assured maximized ingredient yield and the associated profits.

This article was written by Spencer Lovette, v.p. of engineering for Metron Instruments Inc., Solon, Ohio, manufacturers of casein measuring systems. For more information call 216/332-0592, or visit www.metroninstruments.com.