Fritz Leeman, CEO of the Ohio-based company, started a campaign 10 years ago to become the nation's premier producer of Swiss. Leeman determined that to realize this vision, the plant in Brewster, Ohio (the company also operates another facility in Stockton, Illinois) needed significant updating. The result is a carefully planned production facility that incorporates both processing and building innovations, as well as worker integration.

Brewster's northern-Ohio plant has been operating since 1933. Renovations and additions began in 1994. The final step of the multi-year process, spearheaded by Hendon & Redmond, Inc., culminated in the completion of the 45,000 square foot cheese production facility. The $13.5 million dollar project was completed in March 2002 and involves everything from a milk intake system to brining and wrapping.

The changes increased the plant's production capacity of Swiss cheese by approximately 35%.

This facility currently produces more than 35 million pounds of natural cheese per year. State-of-the-art equipment added to the plant assures that the product is of the highest and most consistent quality possible. The largest quantities made are Regular Swiss, Baby Swiss, Lacey Swiss and Reduced Fat Swiss.

But the improvements were not restricted to function. The plant is also quite striking in terms of its architecture. The original brick exterior of the buildings was kept intact, and additions were designed to conform to the style. And large windows were added, revealing the shiny steel production equipment. It's a dairy plant that resembles a microbrewery.

Brewster basics

Swiss immigrant John Leeman started working at Stark County Milk Producers in 1933, a little more than 100 years after the Swiss cheese industry began. Brewster Cheese was born in 1965 when John and his son Fritz purchased the plant and renamed it Brewster Dairy. The company is operating today under the Brewster Cheese trademark.

Leeman's son, Fritz, now oversees the production of more than 100,000 lbs of cheese a day at the Brewster location. More than 300 dairy farmers provide milk daily to Brewster Cheese in Ohio. Brewster's cheese is sold in supermarket delis and prime food stores throughout the United States. The plant operates seven days a week

Renovation challenges

Brewster's 160,000 square-foot operation is housed in three different buildings. Cheese production, packaging and distribution, and whey processing sit on a 12-acre site. Nelson initially contacted Hendon & Redmond, Cincinnati, to study the feasibility of an addition to house new cheese vats. Faced with antiquated vats, Nelson knew that something had to be done to upgrade his facility to meet growing demand.Hendon & Redmond's study revealed that while replacing the make vats would help in the short term, the remainder of the cheese production operation also needed an upgrade. Brewster then began strategic planning and aligned production to its target markets.

With three distinct operations being housed in three separate locations on the property, and a major state highway running through the property, several options existed for building a new cheese production facility. Would it be most effective to upgrade the existing location and renovate or would it make economical sense to build a new facility somewhere else on the property?

Again, the design firm began studies to determine the best option. The conclusion? Renovating the existing facility would save approximately 35% of capital expenditures and still provide a state-of-the-art cheese-making facility.

In August 2000, Brewster decided the renovation project would completely revamp the cheesemaking facility. A team was formed to include Brewster Cheese, Hendon & Redmond and Gaetano Contractors, the general contractor.

To keep the project feasible and keep the facility operating during construction, some strategic space-saving decisions were made. One such decision directly affected what was produced at the facility. Both Swiss and longhorn-style cheeses had been produced in equal quantities in the same building. The team decided to discontinue the longhorn operations, thus freeing up valuable square footage to expand the Swiss operation.

Once basic space-saving decisions were made, a few other renovation issues were addressed.

First, an open space or void in the plan had to be created within the facility, allowing space for construction work to begin. Provisions were made to allow this void to move smoothly from one area to another. This way, plant operations could continue with the renovation work in progress.

A second hurdle involved property line restrictions. Little room remained to add onto the outside of the building. Although the facility had 40,000 square feet, this area was divided between two floors with roughly 20,000 square feet per floor. The challenge was to take a two-story operation and use it to benefit the process and production flow.

While most new facilities are single-story operations, Brewster Cheese was able to utilize the older two-floor operation to its advantage. With the site land-locked, the two floors added valuable square footage that could not be gained through expansion. The only additional floor space available was gained through a 5,000 square-foot addition for the new brining operation. The design creatively integrated the floor plan and processing technologies, and space was also allotted for central employee facilities to replace antiquated facilities and break rooms across the street.

Changing everything and nothing

Careful planning was crucial so construction would not disrupt normal plant operation. To do this smoothly, a schedule was devised that divided the project into major milestones with multiple coordination goals. This project was particularly challenging because every operation in the facility, except for the milk-receiving areas, storage silos, and pasteurizing areas, was relocated to a new area of the facility. The resulting production flow was almost a mirror image of the original flow.The milk pasteurization and cream pasteurization areas were completely renovated. New controls employing Invensys System's Wonderware™ software with touchscreen operator interface pads were installed for the pasteurizer and separator.

A milk culture room was added and an automatic standardization system installed. This equipment allows for multiple blending and gives Brewster the ability to control the composition of the milk on a daily and seasonal basis. To complete the renovation of this area, a new quality assurance lab was constructed to include a new bacteria lab and quality control lab to house state-of-the-art equipment.

A new starter room was added utilizing primary and secondary starter systems. The ability for direct set was added as well as new controls for automatic starter control recipes.

The first milestone was to create a space for six new 50,000-pound horizontal cheese vats made by Scherping Systems. In order to provide easy access to all areas of the make room, the HCV-50 vats were elevated above the floor for easy cleaning underneath and to promote air flows to prevent phage problems. This was accomplished by creating a high bay vat room in the front section of the building. To do this, the second floor was removed in the area formerly housing the pressing of the longhorn-style cheeses.

The new Scherping vats are fully automated and utilize the same Wonderware control systems. The vats feature a top mounted whey pre-draw system, which reduces fines losses and allows better control of the amount of whey removed, which leads to higher yields. The vats also have an automatic dosing system for rennet, which reduces labor and gives a more consistent product.

The most critical air requirements are here in the make room. The entire building must maintain proper airflows to prevent bacterial issues with the cheese production. HEPA filtered units were brought in to pressurize the starter and vat rooms with highly filtered and cooled air. Brewster had to maintain a positive flow on through the filling area and exhausted through the pasteurization rooms.

On the upper level in the center section of the building, an area was renovated for the Universal Cheese Maker (UCM) filling area. During the production process, curds and whey are pumped from the make vats over to the automated filling area where 10 UCMs are staged. The UCMs used at Brewster are specially designed troughs that are used to form and mold the unripened block of Swiss cheese. The three-foot wide by ten-foot long UCMs are filled with cheese curds and extra whey is drained off during the filling process. The filling and pressing system mechanizes a once labor-intensive process and uniformly fills, presses, and removes whey to begin the process of forming the 1,100 pound blocks.

In the filling area, food safety issues dictated a highly sanitary finish to cover the existing bar joist construction. The existing roof height did not allow enough room for a walkable ceiling to be installed. However, a suspended ceiling manufactured and installed by Arcoplast was selected to cover the existing painted bar joist and utility piping. The system consists of high-gloss gel coated panel sealed to a T-frame. Access points are designed into the layout to allow for easy access to the utility piping above.

After filling and initial draining, the UCMs are transported to the lower level for final draining, pressing, and initial fermentation. In the past, the UCMs were moved manually. The plant employs a motorized mover to transport the UCMs. Initially, an automated conveyor system was considered to move the UCMs from the upper level to the pressing room below.

But it was determined that by installing a special freight elevator and designing a motorized pallet jack to move the UCMs, would save significant capital expenditures with no loss in operating efficiencies.

Brining efficiency

Once the UCMs are pressed and fermentation takes place, they are moved to an automated brining area. An addition for the brining operation was constructed on the back of the building. The existing brine tank located on the lower level in the center of the existing building was a floating brine tank for the large blocks of Swiss. The new addition accommodates a submersible brine tank designed and built by Johnson Industries. The pressing lids are removed from the UCMs and the blocks removed via an overhead hoist and placed in a shallow section of the brine tank where they float before being loaded into the holding cage. A cage holding an array of the 1,100-pound Swiss blocks is submerged into the brine.

The deep pit brine tank allowed for a much smaller footprint for cooling the blocks of Swiss, saving valuable floor space. Constant circulation of clean, cool and sanitary brine around all block surfaces is the key element of submersion brining. Rapid cooling to the block core, uniform salt uptake, shape control and valuable fat preservation are the results.

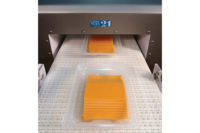

After the blocks have cooled in the brine for 14 hours, they are removed from the cage and floated to an automated lift. The lift transports the block to the wrapping room where the 1,100-pound block is sliced in thirds.

After the block is sliced, the three blocks are packaged in plastic sleeves and placed in containers with inter-locking lids. Brewster is utilizing a new plastic container (traditional containers resemble wood crates), which improves food safety and sanitation. The containers are then sent to a dock where they are loaded on a box truck for transportation across the street to the warming room.

In this room, the blocks are fermented for 15 to 25 days while carbon dioxide is generated, thus forming the characteristic holes of Swiss cheese.

Brewster Plant Facts

Project:Renovation of 1933 cheese plantMajor installations: Enclosed cheese vats, submerged brine pit

Cost: $13.5 million

Project leader: Hendon & Redmond

Annual production: 35 million lbs

Product: Swiss cheese