The use of synthetic food grade lubricants, very common overseas, is now spreading rapidly in the United States.

The reason?

Synthetic fluids and greases in machinery have been shown to prolong oil service life, reduce downtime, and better protect metal surfaces from corrosion and wear. They can withstand temperature extremes and can be tailored to specialized applications. Synthetic food grade lubricants have the additional benefit of being nontoxic to humans. Contamination from lubricants has been a problem for the food and beverage processing industry, where a major accident can result in a massive product recall headache, and damage a company's reputation.

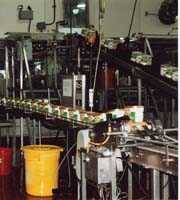

Minor lubricant leaks in machinery are common--sometimes unavoidable even--and are not always as obvious as one might think. Just the normal wear and tear on seals can cause a gearbox or hydraulic system to leak, releasing minute levels of oil that can come into contact with food. Contamination also can come from drips from chains or a release of compressed air that contains an oily mist.

Good engineering and operational practices can minimize, but not eliminate, these threats. So any food or beverage manufacturer who is not using food grade lubricants is operating under an unnecessary risk. Some have switched to the exclusive use of food grade lubricants simply to reduce human error.

If a plant uses a non-food grade lubricant, FDA allows zero amount of lubricant to come into contact with the food. If the lubricant incidentally comes into contact with food, the contaminated product must be discarded. If the plant uses food grade lubricants--which are nontoxic, odorless, colorless, and tasteless--the FDA standards allow lubrication contamination of up to 10 parts per million.

The FDA has specified criteria for the acceptable components used in food grade lubricants. USDA formerly approved specific lubricant products for use in the food manufacturing process. Now NSF International, Ann Arbor, Mich., maintains the Class H1 list of acceptable lubricants.

Food manufacturers can choose from a range of mineral and synthetic oils and greases, but performance differences between them can be significant.

General industrial oils and greases (non H1) have been used in food and beverage manufacturing in the United States, but the potential for contact with consumable products makes them less than ideal for these applications.

Common food grade mineral-oil-based products have helped companies meet the USDA and NSF H1 food grade requirement, but they often fall short of the lubrication performance requirements of modern food processing equipment.

The mineral-based lubricants usually are less expensive than synthetic lubricants but these "white oils" may not perform adequately under extreme conditions of load and temperature. Synthetic lubricants can be specifically designed for high performance, whether for the extreme low temperatures of freezers or for the high temperatures of ovens.

The increased oxidation and thermal stability of a synthetic lubricant, compared to a mineral or white oil based product, make them more effective. Synthetic lubricants and their filters also need to be changed less often, reducing the potential for spills and the disruption of production lines. Synthetics also respond better to performance additives, which is important because of FDA restrictions on the type and concentration of additives allowed in food grade oils.

Historically, companies and food safety inspectors have ensured against contamination by using spot-checks of manufacturing equipment and processes, along with tests of the finished product.

As FDA has required use of Hazard Analysis and Critical Control Point (HACCP) for a wider array of food segments, many major food producing companies are using the HACCP system, but do not always recognize the importance of a lubrication survey.

HACCP surveys should consider all lubrication points to be critical control points, or areas of potential risk. Lubrication surveys should focus on issues such as whether the properties of the lubricant match the use; the type and frequency of maintenance; if the equipment design permits easy access for lubrication without incidental contact with foods; and if lube recirculating systems are functioning.