Articles by Richard Mitchell

Leveraging sustainable ingredients from virtuous suppliers is becoming a standard operating strategy.

Read More

The keys to dairy distribution

Processors must effectively manage a host of operational issues to cut delivery costs and maintain product quality.

June 14, 2024

How to select the proper primary packaging

Not only must processors leverage designs with the proper functionality, but the packaging must also meet their cost and sustainability requirements.

May 16, 2024

How dairy processors can handle cybersecurity threats

Learn what areas of a dairy plant bad actors try to attack, and potential ways to prevent it.

April 22, 2024

When to replace pumps and valves

Processors must analyze a host of variables when implementing an efficient operation.

March 14, 2024

Keeping dairy products safe and sound

Rigid and flexible packaging trends aim to meet the needs of processors.

February 28, 2024

Creating the perfect cultured dairy products

Dairy processors must meet the needs of an increasingly diverse consumer sector.

February 21, 2024

Inclusions continue to meet consumer needs

Fruits and nuts forecasted for high inclusion growth through 2027.

February 15, 2024

Inspection technologies key to food safety

By enhancing food safety and preventing product recalls, the use of highly effective systems can protect the reputation of dairy brands.

January 25, 2024

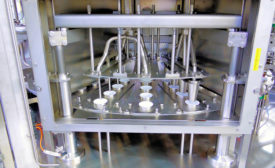

Aseptic and ESL growing in importance

Extended shelf life and aseptic processes are becoming increasingly popular as dairy processors seek to keep pace in an increasingly competitive market.

December 4, 2023

Stay ahead of the curve. Unlock a dose of cutting-edge insights.

Receive our premium content directly to your inbox.

SIGN-UP TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1710441521&width=275)