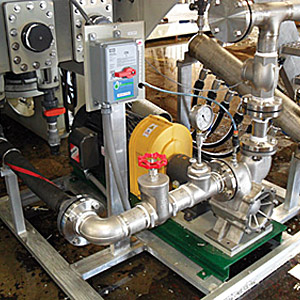

offers increased removal efficiencies and reduced chemical costs. The system’s Nikuni pumps produce micro-bubbles 5 to 15 microns small and dissolved-air saturation to remove even the tiniest pollutants from wastewater, while requiring far fewer chemicals. WWW has used DAG to successfully upgrade many food, beverage and dairy facilities over the past 12 years.

offers increased removal efficiencies and reduced chemical costs. The system’s Nikuni pumps produce micro-bubbles 5 to 15 microns small and dissolved-air saturation to remove even the tiniest pollutants from wastewater, while requiring far fewer chemicals. WWW has used DAG to successfully upgrade many food, beverage and dairy facilities over the past 12 years.

800-607-7873; www.WorldWaterWorks.com