FleetwoodGoldcoWyard’s robotic rotary case palletizer offers companies the ability to palletize multiple product types simultaneously.

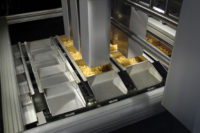

FleetwoodGoldcoWyard’s robotic rotary case palletizer offers companies the ability to palletize multiple product types simultaneously. The robotic rotary case palletizer has the capability to palletize up to eight different SKUs of product in unison. The system is designed for companies currently palletizing multi-product, rainbow packaging, or with multiple production lines feeding a common palletizer. FleetwoodGoldcoWyard’s robotic palletizing solution is capable of handling an array of case sizes and layer patterns at the same time. When utilizing a bar code reader, the system not only indicates proper pallet position for robotic placement for a specific SKU but also rejects misprinted cases automatically. Additionally, the pattern controls allow for greater flexibility in pattern selection including options such as “label out” placement of cases.

FleetwoodGoldcoWyard’s end-of-arm tooling expertise allows for handling various product types and configurations, such as single packages as well as entire rows or layers of product at a time. The robotic case palletizing systems can operate in the harshest of environments including sub-zero freezer applications.

The unique configuration of the rotary case palletizer provides single point of interface for fork lift, while providing a compact space saving layout that can be “tucked” into a small area in your facility. The rotary case palletizer is hands down the most space saving concept for multi-line palletizing.

FleetwoodGoldcoWyard also offers a wide range of other robotic palletizing systems to handle a variety of products such as cans and ends (food, beverage, and paint), cases, trays and bags.

FleetwoodGoldcoWyard

314-862-8000

www.barry-wehmiller.com

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing