Indeed, many anticipate that sodium will be the next nutrient to be labeled taboo. Unfortunately for the dairy industry, cheese is among the leading classes of foods in terms of sodium contribution to the diet, rendering cheese a perfect target for the anticipated "lowering salt" movement. However, before you start cutting back on the salt added to the cheeses your company manufactures, take note that salt plays a very important role in cheesemaking. And, in response to Berlack's projection, cheesemakers might simply need to educate consumers that a healthy diet does not exclude cheese. The key is moderation.

Salt's role in cheese

Added salt (sodium chloride, which has the chemical designation of NaCl) is the primary source of sodium in natural cheese and a major contributor of sodium in process cheeses. In process cheese, sodium-based emulsifying salts also contribute to total sodium levels.The problem with salt in natural cheese is that salt is a critical ingredient in the cheesemaking process. Salt is almost always added after the desired pH is reached, as salt slows the growth of starter cultures. Salt can be added via a salting step, where salt is added directly to milled curd. It can be added by rubbing salt on formed cheese. Or, salt can be absorbed by the cheese as it soaks in a brine solution. Regardless of its method of addition, salt provides taste and texture. More importantly, salt provides safety in terms of acting as a natural preservative. Salt lowers the water activity of cheese, which prevents the growth of undesirable microorganisms. It also controls fermentation and proteolysis by regulating starter cultures and enzymes. Unsalted cheese is virtually unsalable. It is bitter and bland, with an unacceptable soft body and very short shelflife.

So you see, salt is necessary in cheesemaking, as well as in the diet. This is because the human body needs sodium to survive. Sodium is important for regulating the body's fluid balance, maintaining proper blood pressure and volume, and sending nerve signals. Sodium is in fact an essential nutrient, just like the taboos of recent times-fat and carbohydrates.

A great deal of research on salt and sodium levels in cheese has been conducted on Cheddar, as Cheddar is the U.S. leader in American-style natural cheeses. For example, research shows that salt-to-moisture ratios of 4:6 are recommended for optimum Cheddar flavor development and for the prevention of excessive proteolysis and bitterness. In addition, consumer studies suggest that at least 1.25% NaCl is required in Cheddar cheese to ensure minimal consumer acceptance and shelflife. For the most part, Cheddar cheesemakers typically target 1.50% to 1.75% salt in the finished product.

Salt has many functions in cheese, which is why salt cannot be simply reduced or eliminated in natural cheese. Finding a suitable substitute for NaCl has been difficult because of its unique, pure salty taste and flavor-enhancing properties. One method of lowering the sodium content of Cheddar cheese is to use specialty salts that are processed in a way that when applied topically to curd, less is needed because of the way it is absorbed. This enables cheesemakers to use less NaCl by volume.

Another method is to replace some of the NaCl with KCl (potassium chloride). The ionic strength of KCl helps overcome some of the water activity issues associated with simply reducing NaCl levels.

Here's an exciting added perk. By replacing some sodium with potassium, cheesemakers can increase the potassium contents of cheese, rendering such cheese a functional food (see this month's special feature for further discussion.) And, according to the American Dietetic Association, Chicago, sodium and potassium are both very important minerals that your body needs to maintain good health, with most adults not consuming enough potassium.

In addition, FDA has approved the health claim: Diets containing foods that are a good source of potassium and that are low in sodium may reduce the risk of high blood pressure and stroke. However, in order to make such a claim, a product must meet other composition criteria regarding fat, saturated fat, cholesterol and sodium levels. Thus, though a potassium claim is unlikely on low-sodium cheese, potassium's healthful halo transfers over.

Cheese as a potassium carrier

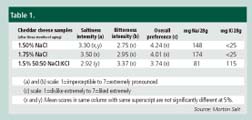

Various "lighter" salt ingredients based on KCl are available to cheesemakers. For example, a 50:50 blend of NaCl:KCl can be used as a direct replacement for all the salt added during curd salting. The end product will have at least a 40% reduction in sodium content and about 350% more potassium.Despite KCl's inherent bitterness, it has been successfully used to partially replace NaCl in certain cheeses. Some studies even indicate that the bitterness in these cheeses is not a result of the KCl, rather it comes from bitter peptides produced when casein is degraded to high levels of intermediate-length peptides. This is when culture and enzyme selection becomes important, and suppliers of both have options available to render this situation. It is also possible to use a lower level of KCl if any off flavors develop. Cheesemakers can accomplish this by in-house blending of NaCl with KCl.

From an economics point of few, NaCl:KCl ingredients cost more than pure NaCl; however, if a cheesemaker was to simply lower NaCl without adding KCl, the weight of the NaCl would be replaced with cheese solids. Cheese solids cost a great deal more than NaCl:KCl ingredients.

From a practical standpoint, KCl may not be approved for use in certain standardized cheeses; however, there is a standard for low sodium Cheddar and low sodium Colby. The standards state that these low sodium cheeses must not contain more than 96mg sodium per pound. Such low sodium products must also be labeled that they contain a salt substitute.

When lowering sodium levels with ingredients such as NaCl:KCl blends, labeling regulations allow for the use of content claims such as "reduced sodium" and "less sodium" for select cheeses. Ingredients statements simply state: Salt, Potassium chloride.

Sidebar: Don't Reinvent the Wheel

The use of KCl in cheesemaking has been studied extensively. Below is data from research conducted at the University of Wisconsin on Cheddar cheese. Results showed that a 50:50 blend of NaCl:KCl produced an acceptable body, texture, shelflife and flavor, although saltiness intensity was lower and bitter flavor slightly more pronounced.Sidebar: Salt Selection Tips

1. Salt crystals vary in size, and thus performance.2. The finer, more granular the crystal, the quicker it dissolves.

3. In vat cheesemaking, coarser salts may only require one addition, as they dissolve slower, which means less salt is lost through the whey. Finer salts may require two or even three additions.

4. If salt is added by a dry-surface rub, slow-dissolving flakes or coarse granules should be used.

5. When making brine, flakes or fine granules should be used, as coarse granules can sink to the bottom of the tank and accumulate.

6. Once an operation is defined and finished product targets are consistently met, salt type and size should be maintained.