Perhaps the most sophisticated hardware among these is the continuous freezer, and it's the machine that continues to offer new innovations for the ice cream maker. These innovations include machines that are adaptable to off-the-shelf PLC controls, machines that offer faster start up and other features designed to reduce waste, and even a new feature that automatically adjusts airflow rates to compensate for fluctuations in barometric pressure.

"Overrun accuracy is always being scrutinized," says Gustav Korsholm, managing director of Tetra Pak Hoyer. "We have important features that have been developed lately."

One is the barometric pressure feature, another is a mass flow meter that helps compensate for air in mix, which is particularly problematic in rework.

Barometric air pressure changes can result in up to 6% change in the amount of air that is dissolved into the ice cream." Korsholm says. "So having a freezer that can automatically compensate is very beneficial."

Another concern that is being addressed by new features in continuous freezers is that of air pockets in the mix. Korsholm said this is a fairly common problem when reworked ice cream mix is introduced to the freezer.

Most manufacturers think that a standard mass flow meter will solve the problem, but unless it is sensitive to density, it only makes the problem worse.

"What is really needed is a sophisticated mass flow meter with accurate density measurements that tells you how big is the flow change so that you can use that information to compensate for the air in the mix."

As noted previously in Dairy Foods (Nov. 2003 p. 42) new low temperature continuous freezers are allowing processors to manufacture ice cream that tastes creamier at lower fat levels. Korsholm says the same technology is being applied to extruded novelties, and works particularly well for ice cream sandwiches. He says too that an added benefit is being discovered-processors have more time between extrusion and hardening to work with the product, meaning more opportunities for packaging.

Hardeners

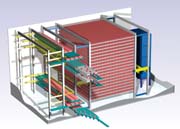

Most ice cream products have to undergo a hardening phase after they are formed, and the most common tools for achieving this are tray hardening tunnels or spiral hardeners. This equipment is fairly simple in design and in general the same kind of equipment is used in various food industry applications including baking and further processing for poultry.One relatively new development that has been put to use in poultry is fully enclosed, welded steel spiral freezers. Because they are sometimes massive in scale, spiral freezers are often fabricated the way a cold storage room is made, from construction components. Walls, floors and ceilings are seamed together with caulking or epoxy, which presents some hygienic concerns, depending on the application.

The solid, enclosed units have some size limitations, but they can be made fully CIPable. For certain frozen dessert applications this can allow naked unpacked product to be hardened with a spiral.

Chillers and Ice Builders

Instant chillers, falling film chillers, and ice builders have a number of applications for the dairy processor including basic refrigeration, and the cooling of product liquids and brine solutions.CLICK HEREfor the Freezer and Chiller Showcase