That's usually not a problem, but when water use and waste stream loads do become an issue, dairy plants can quickly discover that there is plenty of room for improvement. And in many cases those improvements in water management can offer a positive ripple in the bottom line.

The approaches that dairies can take to water use and wastewater flow run the gamut from the reinforcing of common sense practices to sophisticated systems for recapture, reuse and load reduction.

Sinton Dairy, Colorado Springs, was laying the groundwork for a plant expansion that would add a new cottage cheese and sour cream room (see related story p. 52) when it began looking at ways to reduce its water use.

"It started with a conversation with the city utilities and we decided to try to attack it," says Operations Mgr. Bill Keating. "Colorado went through a severe water shortage in 2002."

Sinton, which produces a full line of dairy products for distribution in the western states, knew it would gain some water efficiencies with the new installation that drove the expansion, but a plant-wide water use audit lead to several other system and procedural modifications. The end result was a 25% reduction in water use.

"People can contribute a lot toward conservation just by shutting off a running hose when it's not being used," noted Joel Midkiff, Sinton's general mgr.

Indeed much of the savings did come about from things like fixing leaks, and installing more efficient spray washers for packaged products. But another big savings resulted from reusing the cooling water in the ammonia chillers used for plant refrigeration.

"We used to run that water through once and then send it down the drain, now we re-cool it and treat it," Keating says. "Plant-wide we had been using about 4 million gals of water per month, and now we have it down to 3 million. I'd say about a half-million of that savings is from the ammonia chillers. It was a sizable difference."

Sinton conducted its water audit internally beginning in the spring of 2002 and was able to implement changes over the course of just a few months. The expansion, completed in the spring of 2003, helped complete the 25% reduction in water use. Keating and Midkiff say the best part was that the ideas came from people throughout the plant.

"Originally the quality mgr., Amanda Moore, put together a bulletin board, letting everyone know what we were trying to do," Keating says. "We put out a suggestion box, and we got feedback from maintenance workers and production workers, and not just from the engineers. We got a lot of involvement from the whole plant."

The municipality provided no carrot or stick incentives, but Sinton did receive a special recognition as a Colorado Springs "water champion."

Save the milk

While Sinton found many incremental solutions to its water concerns, Milkco Inc., a national contract dairy packager based in Asheville, N.C., focused on one major solution to a different water issue.While implementing new control software, Milkco began thinking about recapturing milk that would otherwise make a nutritional contribution to no one other than the microorganisms at the wastewater treatment plant.

Since 2001, Milkco has been recapturing that milk, and it's thought to be the only facility in the U.S. with FDA approval to reuse it as Grade A product.

"Like any processor, you look at where your waste is on a regular basis and try to make improvements. You have to rinse the tanks so we understood that there were solids going to the drain," says Jack Levins, an engineer with Milkco. "At the same time, we were working with our engineering firm Gannet Fleming, and they told us that they had wanted to participate in something like this. We decided to put the system in and decided to go to FDA for approval to use it for buttermilk."

The system at Milkco uses a battery of double-block-and-bleed mix proof valves and an independent recapture line and tank system that has been incorporated to the dairy's CIP system.

"Most CIPs have a first rinse," Levins explains. "A recapture will use a pre-rinse, that starts with a totally separated ozonated water source and you capture that."

FDA requires that the water used be the equivalent of pasteurized water, and ozonation provides that, Levins say. A separate recapture line takes that first rinse to a set or holding tanks.

The system uses an infrared sensor that measures solids of the material headed to the recapture tanks.

"If it's above 4% it goes to storage, when it's below, it goes to the drain," Levins says.

The end result is that Milkco is putting more of its milk into packaging and less of it into the waste stream.

A filtration system is used to remove the water and the remaining product is mixed one-to-one with new product then fermented to produce buttermilk.

"Because we're a contract packager, our processing changes on a daily basis, so it's hard to say what the impact is on our BOD (biochemical oxygen demand)," Levins says. "We base it more on recovery, with the understanding that it would reduce BOD. In a typical day the system recaptures about 2,500 gals with a 4% solids level."

Levins estimates that through sewer surcharge and water use reductions, Milkco also saves about $275,000 a year.

Specialized on-site treatment

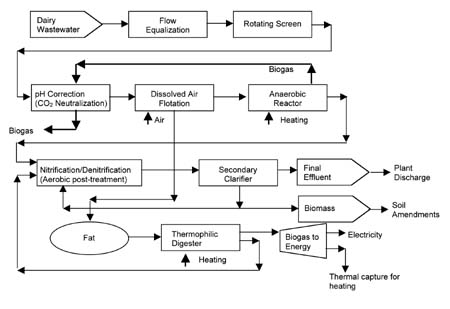

Another area where water use efficiencies are being created is in-house treatment of wastewater.In most cases, if dairy wastewater is treated on site, it is done so biologically in aerobic systems, often in combination with a physical-chemical pre-treatment. Few full-scale references with anaerobic treatment of dairy wastewater exist because of non-conducive wastewater temperatures, inherently high concentrations of fat and commonly used detergents and other cleaning chemicals that hamper anaerobic degradation.

With specially designed pre-treatment equipment intended to reduce excess biological sludge production, energy consumption and chemical consumption, biological treatment in an anaerobic reactor can be successfully and economically conducted. Furthermore, supporting technology added in parallel can provide an environmentally friendly and hygienically optimized system for the removal of fat.

One such advanced design offered in the United States by the exclusively licensed team of Infilco Degremont, Inc., Richmond, Va., and Biotim S.A., Brussels, Belgium, addresses all of these considerations and involves the use of thermophilic digestion of fat from a dissolved air flotation unit. An additional key part of this approach pioneered by Infilco Degremont, involves the use of CO2 for pH neutralization. According to Rich Ubaldi, Infilco Degremont's vice president, the resultant integrated process benefits from the ability to use the biogas produced as both a CO2 source and a combustible fuel that can be used to power electrical generators for low-cost on-site electricity.

Paramount to the economies of this design is the ability to fully control the temperature to proper levels in the thermophilic fat digester using the excess thermal energy captured from the generators. With the application of these novel processes, Infilco Degremont and Biotim are able to effectively and efficiently treat widely varying contaminants contained in dairy processing plant wastewater to regulatory thresholds with an acceptably short payback period on investment.

A CIP solution

ew filtration technologies allow processors to extend the life of CIP solutions and thereby introduce less cleaning chemicals into the waste stream.A novel tubular membrane filtration system, called Reco-CIP, provides dairy processing plants with a cost-effective method of recycling caustic and acidic cleaning solutions. The Reco-CIP system, developed by PCI Membrane Systems Inc., Milford, Ohio, uses tubular nanofiltration membranes.

For dairy processors who typically clean their equipment "in place" without dismantling it, the PCI Reco-CIP system offers a way to reduce waste volume and avoid exceeding daily discharge limits (and potential surcharges and fines) imposed by municipal waste authorities. This makes the system ideal for large and growing processing plants challenged by emissions limits.

"The key of the system really is the membrane," explains PCI North American sales manager Lewis Pain. "Dairy processors circulate these cleaning solutions through processing equipment that's being used for milk or lactose, and in doing that they're bringing into solution proteins, sugars, and other contaminants that get clogged or burned onto the equipment. So the membrane has to be able to hold back as many contaminant components in the cleaning solution as possible." The system allows the filtered, clear caustic cleaning solution to be used a second, third, fourth time or more, he adds.

PCI estimates that the performance of the membrane modules and the low cost of installation allows users to recover the cost of a Reco-CIP system in less than a year, depending on plant requirements, the value of recovered chemicals, and savings in waste disposal costs. In some cases, the retained solids from the cleaning solutions-which include proteins and sugars-can be neutralized with acid and then used in animal feed.

The tubular membrane design of the system means that membrane cleaning and maintenance demands are low. In tubular "crossflow" membrane filtration, the process liquid (in this case, contaminated cleaning solutions) flows tangential to the membrane surface. This is quite different from conventional filtration, in which the feed flow is perpendicular to the membrane surface causing debris to build up on the membrane surface and inhibit fluid permeation. With crossflow filtration, however, pressure drives some of the liquid through the membrane, while the rest continues to circulate and sweep debris off the membrane surface. A Reco-CIP system configured for nanofiltration can be run in continuous or batch process modes for up to 22 hours between membrane cleanings, and its modular design streamlines the cleaning procedure.

Capable of operating at pressures from 14 to 28 bar and temperatures up to 140