In its most basic application, a centrifuge spins milk at high speeds, separating the heavier fat globules from the serum, or milk. Processors can then standardize the milk by reintroducing the milk fat at specific proportions for low-fat and whole milk products, and other dairy products such as cheese or ice cream. Other dairy applications of the centrifugal separator include whey and WPC separation, and separating milk proteins for drying. Separators can also be used as clarifiers, to separate foreign material from raw milk, to separate cheese fines from whey, and to aid in removal of some strains of bacteria that are able to survive standard pasteurization procedures.

The centrifuge cream separator was developed in the 1880s by Gustaf de Laval and led to the formation in 1883 of the company known today as Alfa Laval, one of the major manufacturers of separators and other processing equipment.

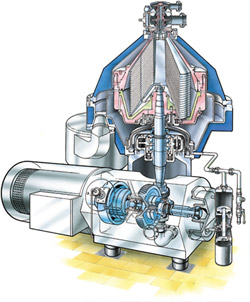

The original machine was manually operated, but eventually motor drives were added. While the basic engineering of a separator has changed little in 100-plus years, performance, safety and control features have been continually improved.

Separators are used in a number of applications besides

dairy, including food and pharmaceutical manufacturing, industrial fluid separation and wastewater treatment. They are available in a variety of sizes and capacities from pilot-plant sized units to monsters that can separate several million pounds of milk a day.

Running hot and cold

Milk separation occurs most effectively at elevated temp-eratures, generally 120-145°F. At much lower temperatures, cream viscosity and a number of other factors have an adverse effect on separation efficiency. At much higher temperatures, the reduced tendency of fat globules to agglomerate has a negative effect on skimming efficiency and increased fouling of the separator, caused by protein precipitation, can reduce run times between cleaning cycles.Separators that have been specially designed for warm-milk separation operate with a minimum product temperature of between 68 and 78°F.

For some applications, it may be desirable to separate cold milk at product temperatures of 40 - 55°F. These lower temperatures can be accommodated in specially designed cold milk separators. Cold milk separators are designed very differently from their warm milk counter parts and generally have a much lower capacity than the equivalent warm milk separator. Cold milk separators have capacities ranging from 5,000 - 55,000 lbs per hour. Comparatively, warm milk separators run at capacities as high as 150,000 lbs per hour.

While cold separation is less efficient, some processors say it results in better-tasting fresh milk products.

Setting the standard

Standardization of milk involves the adjustment of the fat content of milk, or a milk product, by addition of cream or skim milk, as appropriate, to obtain a given fat content.

In modern milk processing plants with a diversified product range, direct in-line standardization is usually combined with separation. Previously the standardization was done manually, in standardization tanks. As processing volumes have increased, there has become a need for fast, constant and reliable standardization methods that can respond to seasonable fluctuations of the raw milk fat content. Control valves, flow and density meters and a computerized control loop are used to adjust the fat content of milk and cream to desired values.

Innovations

One of the stickiest problems in milk separation is the disruption of fat globules, which can cause sticking problems and increased sensitivity to oxidation and hydrolysis. For this reason, equipment manufacturers are always seeking engineering modifications that will allow for a gentler separation of milk.A solution offered by one manufacturer, is the development of hermetically sealed separators. In these units, the entire separator bowl is filled with milk, and there is no air in the separator. Newer inlet and outlet designs also work to provide a gentler handling of the milk. Hermetic design also allow for a higher concentration of fat in the separated cream, and for greater process flexibility and lower power consumption.

Like most dairy equipment, separators are made primarily of stainless steel. Engineering advances have lead to machines that consume less energy and water, and that wear more slowly, thereby requiring less maintenance. One manufacturer recently introduced a new seal that in effect never needs to be replaced. Another innovation allows shorter and fewer ejection cycles which leads to less loss of milk protein and other benefits like reduced wear and maintenance and lower energy and water consumption.

Complete modular design of separation and in-line standardization systems have become more and more popular, particularly for companies designing new plants or extensive facility expansions.