Home » Keywords: » cheese manufacturing

Items Tagged with 'cheese manufacturing'

ARTICLES

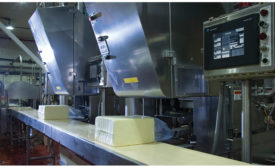

LaClare Creamery is the epicenter of goat cheese production

Goat cheese processor supports nationwide distribution with expanded dairy plant.

March 4, 2024

Cheese news

Bongards Creameries plans $35 million expansion in Tennessee

The Minnesota dairy co-op will add 80,000 square feet to its plant in Humboldt, Tenn.

July 28, 2017

This week in dairy processing

Butter sales are strong; cheese stocks are building, says USDA

Domestic butter demand is steady and international demand is good. Milk supplies are adequate for cheese processing in all the regions.

July 21, 2017

Cheddar chatter

Agri-Mark’s Cabot, Vt., facility is the 2017 Plant of the Year

Cabot Creamery makes Cheddar and specialty cheeses plus yogurt and sour cream.

July 10, 2017

Curds and why

Have a cheese problem that needs solving? Ask the Cheese Doctor during our free webinar

Don’t know how to avoid defects in your cheese? Ask John Lucey, the Cheese Doctor.

May 29, 2015

What Chobani & Glanbia know

Idaho: Famous for Potatoes. Famous for Milk & Cheese

A massive amount of milk is produced in southern Idaho. It's turned into cheese, yogurt and other products.

March 28, 2014

Ingredients

Nutrilac FastRipe opens door to huge savings for cheese producers

February 14, 2014

Stinky cheese? Not anymore

Cheese plant resolves odor issues

BioAir's EcoBase synthetic media is specifically designed to provide uniform and optimized mass transfer of odorous compounds under a controlled microenvironment.

January 23, 2014

Holland’s Family Cheese: How we make the best cheese in the United States

Holland’s Family Cheese was named the Grand Champion at this year’s United States Cheese Championship Contest. Here’s the behind-the-scenes story of how that came to pass.

August 26, 2013

EVENTS

Industry

9/11/12

Dairy Products Technology Center

Cal Poly State University

San Luis Obispo, CA

United States

Contact: Laurie Jacobson

15th Annual Dairy Science and Technology Basics for the Farmstead/Artisan Cheesemaker

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1711045885&width=275)