Home » Keywords: » secondary packaging

Items Tagged with 'secondary packaging'

ARTICLES

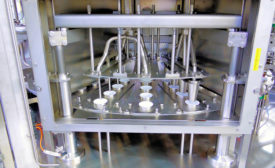

Extended shelf life and aseptic processes are becoming increasingly popular as dairy processors seek to keep pace in an increasingly competitive market.

Read More

Secondary packaging becomes a more dynamic dairy processing component

Upgrades are keeping pace with the greater sector demand for eco-friendly designs with added product safeguards.

August 24, 2023

What to look for when choosing secondary packaging equipment

We highlight the benefits of certain secondary packaging machines and what they can do for manufacturers of dairy foods and beverages.

January 11, 2017

Displays that POP

Club store POP display for dairy products uses direct-to-corrugated print technology

Noga’s display box was produced with particularly tight registration, as seen in the bar-code printing and the small font copy.

March 25, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing