|

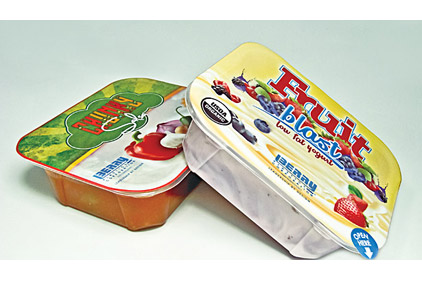

| Easy Peel Lidding for high-pressure pasteurization results in reduced leaker rates, increased production, assurance of package integrity and an easy to open package, according to Berry Plastics, which was honored with a Silver Award from the Flexible Packaging Association. |

Modern-day dairy processors might find a use for a new flexible package made from an edible and water-soluble film. Pouches made with the films are designed to dissolve and release their contents when exposed to hot or cold liquids. The dissolved film can then be safely consumed. Dairy processors selling to the foodservice and food manufacturing markets (where pre-measured quantities are important) might find this of use.

At the July IFT Food Expo in Chicago, Monosol, Merriville, Ind., promoted its Vivos Edible Delivery System. The film, made of food-grade ingredients, is transparent, odorless and tasteless. It can be formed in bags or pouches using existing converting technologies.

According to the company, any powder or low-water-content liquid will work with Vivos film. According to Monosol, the film can be “beneficial as a manufacturing and/or cooking aid to deliver ingredients during the manufacturing of food and/or beverages.” Examples of ingredients include food colors, enzymes, vitamin fortifiers and yeasts. Products contained in the package include nutraceutical items such as workout supplements and fiber supplements. A MonoSol test protocol can be used to determine compatibility of the food with the film.

One benefit of using the film is that there is nothing to throw away after consumption. Other benefits to end users are on-the-go convenience and portion control.

Award-winning lid

Berry Plastics Group, Evansville, Ind., received three Flexible Packaging Association Achievement Awards at the Association’s annual ceremony in April. The FPA honored Berry Plastics with a Silver award for technical innovation for its Easy Peel Lidding for High-Pressure Pasteurization package (see photo). Product benefits are said to include reduced leaker rates, increased production and assurance of package integrity through distribution and retail.

Another supplier of flexible films is Covington, Ohio-based General Films. It serves a wide range of industries, offering custom extruded film solutions, bag-in-box systems and industrial packaging. It advises dairy processors to consider total costs — not initial costs — when selecting packaging materials.

“Even though higher-quality films cost more, their benefits save processors in the long term by protecting the product better and for longer,” General Films President Tim Weikert told Dairy Foods.

Weikert said that thinking only about short-term benefits can drive up costs over time.

“This approach may look good on paper, and may even make sense in many situations, but in some cases, it ends up being shortsighted as complications from the cheaper (usually lower quality) films begin to crop up down the line. The resulting losses in product, productivity, and customer satisfaction caused by the failure of the cheap films far outweigh any short-term gains made in profitability during procurement.”

Find suppliers of flexible packaging in the July Dairy Foods Buyers Guide and at Pack Expo, Sept. 23 to 25 in Las Vegas.