Home » pumps

Articles Tagged with ''pumps''

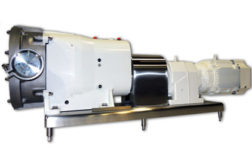

New pumps and valves for dairy plants

Valves provide protection for dairy processors

April 19, 2013

Dairy operations

Cleaning pumps and valves

Pumps and valves need to be cleaned thoroughly to eliminate allergens. Temperature, pressure, velocity and cleaning solution are some of the parameters to follow.

April 18, 2013

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing