Dairy Foods:All types of proteins are being recognized as part of the solution to get Americans to eat more healthfully. There are a myriad of isolated dairy proteins available for use as an ingredient in all types of foods and beverages. Dairy Foods magazine wanted to find out what's the word in the world of dairy protein-containing foods and beverages. So we talked with 11 companies either involved in the manufacture, marketing and use of dairy proteins, or sell other ingredients that are often included in dairy protein formulations. Here's what they had to say:

Mulvihill: Dairy proteins are a business that Kerry has been involved in from the very beginning-more than 30 years ago. We were and still are fortunate to have a large, high-quality milk supply in Ireland. This supply is much larger than what is required within Ireland for consumption, so proteins are a logical end product to produce. We have evolved over the years from making just casein and caseinate-type proteins under the Kerrynor™ brand, to producing a full range of ultrafiltered milk proteins and derivatives under the Ultranor™ brand. Most recently we have further developed the technologies to produce application- and functional-specific products for a wide range of end uses.

Chaudhari: Even though we don't manufacture dairy proteins, we formulate the custom premixes containing vitamins, minerals and other functional food ingredients. Premixes add value and improve the overall nutrient profile of many different applications.

Mulvihill: Dairy proteins are a business that Kerry has been involved in from the very beginning-more than 30 years ago. We were and still are fortunate to have a large, high-quality milk supply in Ireland. This supply is much larger than what is required within Ireland for consumption, so proteins are a logical end product to produce. We have evolved over the years from making just casein and caseinate-type proteins under the Kerrynor™ brand, to producing a full range of ultrafiltered milk proteins and derivatives under the Ultranor™ brand. Most recently we have further developed the technologies to produce application- and functional-specific products for a wide range of end uses.

Chaudhari: Even though we don't manufacture dairy proteins, we formulate the custom premixes containing vitamins, minerals and other functional food ingredients. Premixes add value and improve the overall nutrient profile of many different applications.

Chaudhari: Dairy proteins have the highest bioavailability, or protein efficiency ratio (PER). Dairy proteins prove to be an excellent base to add value-added products containing vitamins, minerals and other functional food ingredients.

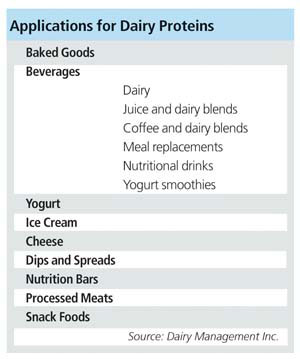

Gutiérrez: Dairy proteins can be incorporated in a very broad range of foods. The milk proteins are receiving more recognition as a premium source of nutrition around the globe. Asian cultures that had little "dairy consumption culture" as part of the traditional diet have within the past 20 years really embraced dairy products as major contributors to the physical development of young children. Recently, much attention has been focused on the benefits of whey proteins for the contribution of lean body mass composition and cardiovascular health. The industry is enjoying a significant shift in United States' cultural acceptance that dairy-based, high-protein diets are good for all ages, not just for body builders and athletes.

Dairy Foods: How have dairy protein ingredients evolved in recent years?

Harris: In general, whey proteins have come a long way to becoming a protein of choice for use in foods. The nutritional benefits of whey proteins for sports nutrition have generated a demand for whey in many applications, including beverage powders, ready-to-drink low-acid beverages and nutritional bars. The amino acid profile (BCAA) and high PER values have played a large role in this success. Suppliers are also looking at the individual fractions of whey to showcase benefits (i.e. lactoferrin as an antimicrobial and for iron binding). More functional whey proteins are being developed to help with shelflife in food systems such as nutritional bars (i.e., maintains softness over time), bakery items (i.e., replaces eggs and binds water) and dairy applications such as yogurts (i.e., helps control syneresis).

Mulvihill: Until a couple of years ago, there were a few broad categories within the dairy protein market-whey, casein and ultrafiltered milk proteins-with little differentiation other than protein content. In recent years there has been increasing commercialization of products that have been further processed to more suitably match end application needs. Examples include proteins that have a lower viscosity in liquids and proteins for nutritional bars that extend shelflife and prevent hardness. There has been a move towards increased fractionation into bioactive peptides for specific physiological functions. Combination products have also become more prominent, such as fast- and slow-release proteins for muscle recovery after exercise.

Miller: Dairy proteins have evolved tremendously. First, from the manufacturing perspective, the dairy industry knows more today than ever before about isolating protein components and providing a very clean, consistent, high-quality, purified product. We understand dairy protein chemistry better than we ever have before in terms of gelling, foaming, dissolving proteins for use in beverages or freezing them for use in frozen novelties.

Vosen: There have been some interesting refinements to existing products that en-hance consumer acceptance. For instance, whey protein isolates (WPI) made by ultrafiltration and microfiltration are clear in solution when rehydrated and incorporated into ready-to-drink beverages. A consumer buying a chocolate ready-to-drink beverage might expect it to have thin, opaque milkshake like appearance and mouthfeel, but that same appearance and mouthfeel is not acceptable in a tropical punch beverage, where juiciness and lightness might be the expectation. But it can now be done.

Dairy Foods: What can we expect from technology in the future? Miller: Much of the technology will be based on the enhanced understanding of dairy protein chemistry. These technologies will allow us to manipulate dairy proteins in a way that provides for better utilization in products such as dry powder mixes and ready-to-drink beverages with a wide range of pHs or functionalities. Plus, we see technological advancements in protein-based gels and films and how they can act as moisture or air barriers. As we learn more about the functional benefits of dairy proteins in product formulations they will become a more value-added ingredient relative to other protein sources. The biggest area of opportunity for dairy proteins will be with nutrition and health benefits. Research in this area will provide a lot of future opportunities in product positioning.

Smith: The body of evidence indicates that past nutritional emphasis on the consumption of carbohydrates and fats has led to an overweight population that is more susceptible to diseases such as diabetes. Continued nutritional research and market demand will call for more products to be formulated with more protein. Whey protein is the ideal protein to fill this need. Secondly, the aging of the population will open many opportunities as researchers strive to develop nutritional, protein-rich products for older individuals who struggle to keep enough protein in their diets.

Gutiérrez: Advancements in membrane separation technology are allowing milk and whey protein processors to tailor make proteins to meet very specific and unique functional characteristics. Processors now have the ability to fractionate milk and whey proteins to extract micro components such as lactoferrin, alpha-lactalbumin, lactoperoxidase, etc.

Rippe: I expect refinements in techniques of fractionation and purification will allow specialty variations in functionality of dairy proteins. There will also be improved efficiencies that will make it more cost effective to isolate specialty components. An example would be glycomacropeptide (GMP) from whey that can be used as a food protein source for people with phenylketonuria (PKU) and has potential for promoting satiety in weight loss formulations. I expect current and future nutritional and biochemical studies of dairy protein will reveal fascinating information on the strong positive influence it has in human health and nutrition. What we know intuitively will be supported scientifically.

Chaudhari: Technology in the future will continue to evolve as market demand increases for innovative products worldwide. Whey protein concentrates (WPC) and WPI are both in very high demand for many different applications.

Gutiérrez: The marketplace will dictate if ingredients that are technically feasible will be commercially available to food and medical formulators. When a microcomponent is extracted from a milk or whey protein stream, this

extraction impacts (positively or negatively) the characteristics of the remaining dairy protein. As long as the net economic returns are positive to the dairy processor, then manufacturers will pursue these new ingredients.

Dairy Foods: What product development efforts are your company involved in that require the use of dairy proteins?

Rippe: We look to dairy proteins as a standard component in just about all our product development efforts. When we formulate an instant nutritional beverage we look for the excellent dispersion and solubility of our agglomerated WPCs and WPIs. We combine this with the ability to design a precise nutritional profile delivering high protein, high digestibility and the option of lactose free with a comparatively neutral base flavor profile that is readily flavored. I have found no other protein source to be as versatile as whey in nutritional beverages. Our recent focus is on healthy versions of ice cream. We are testing ice cream formulations with less fat and with added whey protein and other functional ingredients to create the next generation of ice creams. We test the added functionality of whey protein in our stabilizer systems to maximize overrun, mouthfeel, shelf stability and profitability.

Mulvihill: We are launching a new product this spring that will allow development of products that were previously very difficult to formulate. Manufactured through selective fractionation of milk proteins, Ultranor HT-10 is a unique MPC (MPC) that delivers high levels of calcium in a colloidal form. It provides three-times the level of calcium per unit protein than milk. In short, Ultranor HT-10 delivers calcium in a mode that closely resembles that of milk, but in a more concentrated, stable form. Previously when developing liquid applications with high calcium levels there is increasing difficulty with stability the higher you go with calcium levels. Adding certain types of calcium can also have an effect on protein stability in formulations, so the difficulties can be two-fold. Through our unique technology we can deliver very high levels of calcium without affecting product quality, taste and stability. It is possible to get 80%-plus of the recommended calcium intake for an adult in one 8-oz beverage by using this unique product.

Smith: TempPro™ is of particular interest to dairy processors, as it is not an everyday WPC80. It is a special, functional WPC intended to solve problems encountered when processing at high temperatures. Temp Pro was specifically developed for ready-to-drink beverages and UHT/ retort processed products, which outside of the United States may include ice cream. Traditional WPC and WPI products tend to precipitate when used in high concentrations, thereby limiting their use. TempPro has been used in beverages with up to 16g of protein per 100g. Gel Pro™ is also interesting. This WPC80 has been processed in a way that it gels like egg whites. It is used in beverages, yogurts, processed cheese, dressings and the like. Gel Pro thickens and adds body. This can be of particular interest to food formulators looking to eliminate starches and food additives in order to yield a clean label.

Rippe: Our agglomerated Cornerstone® WPCs and WPIs offer exceptional dispersibility and solubility in instant applications. With a proprietary designed agglomeration system, we control increases in the surface area and bulk density of the powder, allowing the whey protein to spread on the water surface, drop in and solubilize rapidly.

Forrest: We are actively engaged in developing new applications for our MPC products to help our customers achieve their formulation goals. Since it is essentially skim milk powder with significantly less lactose, dairy product formulations requiring little or no lactose make MPC an ideal substitute for skim milk powder. For example, standardizing whole milk used for the production of cheese with MPC instead of skim milk powder can increase cheese yields and decrease overall costs. Also, choosing heat-stable products such as Inpro 90 HS, a WPI, is essential in the prevention of undesirable precipitates formed during heat treatment. INPRO 80 LF, a low-fat WPC, is an ideal replacement for skim milk powder in yogurt production. This substitution results in superior sensory qualities, improved texture, stability and gel firmness.

Dairy Foods: Do you think consumers are starting to understand the benefits of dairy proteins in the diet?

Mulvihill: I believe so. There is a positive link in consumers' minds between consumption of low-fat dairy foods and weight management and also there is an increase in understanding of the importance of calcium and its various functions.

Gutiérrez: Repeated publicity campaigns by the industry are having consumers recognize that dairy products "do the body good" regardless of age.

Koski: The "got milk®" and "3-A-Day™" campaigns have done a great job of boosting consumer awareness of dairy foods and increasing demand for healthy dairy options. There is still consumer confusion regarding dairy proteins though. Many consumers do not understand that dairy proteins are separate from lactose, and lactose intolerance does not require giving up all dairy foods. The highly purified dairy proteins are almost lactose-free, which is hard for consumers to understand.

Miller: It goes back to the base product: milk. Consumers have always considered dairy to be a very nutritious source of high-quality protein. Dairy proteins have a good reputation with consumers. Specific proteins, such as whey, are not as well understood among consumers. I think there are some consumers, such as bodybuilders, who understand the value of certain dairy proteins, like whey, but I am not so sure that all consumers know what whey protein is or what it can do. DMI is trying to help understand consumers' needs and find solutions.

Vosen: The types of products we manufacture could only be found in specialty nutrition stores a few years ago. Now you can find these products in more mainstream stores. Consumers are starting to get it.

Rippe: Certainly athletes, body builders and health-oriented consumers are familiar with whey protein. I surveyed the top 60 instant nutritional beverages available for sale on the internet and found that more than 90% contained whey protein. Dairy proteins are not as readily found as an advertised protein supplement in supermarket products yet, but they certainly could be, as any number of dairy protein ingredients can be found in an amazing variety of food labels. Research efforts to describe the health benefits of dairy proteins will undoubtedly result in greater promotion of dairy protein in all the foods that already carry them and create opportunities for others that could.

Jacobson: A constant barrage of promotions heralding the benefits of new ingredients may confuse consumers, but most have trusted dairy products from childhood. We need to continue to educate the consumer about the superior nutritional value of dairy proteins whether consumed in a glass of milk or in a sports drink.

Dairy Foods: Looking into your crystal ball, what role do you see dairy proteins playing in the future?

Jacobson: We expect the reliance on specialty ingredients to grow as the industry continues to modernize. Due to this demand, we expect dairy protein ingredients will continue to evolve to provide more diversified and specific functional attributes. As dairy processing technologies continue to develop, more specialized dairy proteins, both in function and in nutrition, will become available.

Vosen: In the future we will see further fractionation of the proteins in milk. For instance, if skim milk is microfiltered, the whey proteins permeate the membrane along with lactose. That stream can then be ultrafiltered to produce a stream similar to regular sweet WPC but free of casein macropeptide. This would be the ideal starting material for the production of purified alpha-lactalbumin produced using ion exchange technologies. This alpha-lactalbumin-enriched product could then be used to manufacture infant formula more closely matching the protein composition of human milk with reduced allergenicity, because of the reduction in beta-lactoglobulin.

Miller: Dairy proteins are becoming a larger focus of DMI's research efforts, both from the product side and the nutrition side. DMI will continue to explore ways to isolate and produce high-quality dairy proteins and demonstrate the nutritional and health benefits of dairy proteins. We've learned that dairy farmers can benefit from increased utilization and sales of dairy proteins. What used to be a smaller component of our research program at DMI has now become a much larger component. Dairy proteins will continue to gain in importance.