If it weren’t for chocolate milk, there might be some people — perhaps dear reader, even you — who wouldn’t drink much milk at all. Indeed, chocolate milk is a perennially bright star in the dairy firmament, and with fall’s ushering in of the new school year, its glow is bound to grow brighter.

Or, as Blommer Chocolate Co.’s Jeff Krasinski said,“I would certainly think that when school goes back into session and the school lunch program kicks in, consumption of fluid milk, and chocolate milk in particular, comes back.”

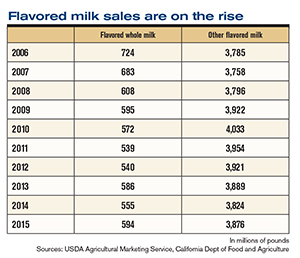

He’s right. But that’s hardly the only time — or place — in which chocolate milk flows. Sales of flavored milks are up nearly 8% over an already-strong 2015, as scientific substantiation of chocolate-milk-as-recovery-beverage — not to mention a spasm of product innovation — win over everyone from fitness fans to foodies. Fancy artisanal cocoas, wild flavor mashups, even chocolate “milks” made from nuts, soy and hemp further expand the market, and the creative possibilities.

If the dairy industry is to build on existing momentum, it must formulate chocolate milk for the way we live today. So we quizzed cocoa and chocolate experts on the ins and outs of optimizing the hottest — or coolest — beverage in the dairy case.

Dairy Foods: Are these boom times for chocolate milk?

Gregory D. Miller, chief science officer and executive vice president, National Dairy Council/Dairy Management Inc., Rosemont, Ill.: Yes. Chocolate milk is seeing growth at retail, in contrast to the category as a whole.

Miranda Abney, director of marketing, Milk Processor Education Program (MilkPEP), Washington, D.C.: We’ve seen strong and continuous growth since Q1 2015. This is an exciting time for chocolate milk.

Dairy Foods: What do you think accounts for its sudden relevance?

Rick Stunek, marketing & sales, Forbes Chocolate, Broadview Heights, Ohio: There’s no question that the two biggest factors are its popularity as a sports recovery drink and its generally positive vibe from a natural and nutritional standpoint.

Abney: Having a new usage occasion for chocolate milk as a post-workout go-to is a great opportunity for the industry. MilkPEP’s national Built With Chocolate Milk campaign is driving demand, raising awareness and improving perceptions on the healthfulness of chocolate milk. The national campaign and strong, credible scientific research behind it positions chocolate milk differently and engages a new audience with adult athletes and exercisers.

Additionally, the campaign taps into the protein trend, touting chocolate milk for its unique carb-to-protein ratio and recovery benefits. Fueled by this and, importantly, brand innovation, flavored milk sales have grown at a significant rate as it’s become increasingly popular as the recovery beverage for a wide audience.

Dairy Foods: But let’s not forget: chocolate milk’s taken its lumps. Some criticize its added sugar and argue that it’s no better than soda. Fair or no?

Dairy Foods: But let’s not forget: chocolate milk’s taken its lumps. Some criticize its added sugar and argue that it’s no better than soda. Fair or no?

Miller: Flavored milk contributes only 4%, on average, of the added sugars in children’s diets and provides the same nine essential nutrients as white milk.

Abney: Registered dieticians and athletic trainers will often tell you that after strenuous exercise the body needs protein and carbs to recover. Chocolate milk has the right mix of carbs — including sugars — and protein that athletes need after a hard workout.

Also, it’s important to mention that not all sugar on a label is “added sugar.” Some of these total grams are naturally occurring lactose. Many leading health and nutrition organizations, including the American Academy of Pediatrics, the Academy of Nutrition and Dietetics and other groups, agree that flavored milk is a positive tradeoff for soft drinks, which are the primary source of added sugars in children’s diets. Studies have shown that children who drink flavored milk do not consume more added sugar in their diets, but rather drink more milk overall and meet more nutrient needs.

Miller: Still, the dairy community has been working proactively to improve flavored milk.

Dairy Foods: How so?

Miller: Since 2007, the U.S. dairy industry has reduced added sugars by about 55% in the flavored milk offered in schools. Today, the majority of flavored milk available in schools is 150 calories or less, with an average of 122 calories — just 25 more than in white milk.

Dairy Foods: But reducing sugars in chocolate milk is tricky. How are formulators making progress?

Wade Schmelzer, principal scientist, Cargill, Wayzata, Minn.: Consumers seek reduced-sugar options, but still want great taste. Dramatic improvements in the sweetness quality of next-generation stevia sweeteners make it possible for dairy manufacturers to achieve deeper sugar reductions than ever before. For instance, replacement of 2% to 3% sugar in chocolate milk was feasible using traditional stevia-leaf extracts. [But one stevia product] can replace over 6% of the sugar.

Dairy Foods: Besides trimming sugar levels, how else is chocolate milk evolving?

Jeff Krasinski, vice president, procurement and risk management, Blommer Chocolate Co., Chicago: Manufacturers offer varieties that are lower in fat or that even boost the protein or nutritional content more generally. Overall, the evolution is driven by consumer choice and is a function of desired tastes and nutritional content.

Miller: In addition to the growing number of higher-protein products, there’ve been some interesting things done in indulgent chocolate flavor blends in the last couple years, many geared to adults.

Stunek: We’ve seen so many combinations with chocolate, including chocolate cherry, chocolate banana, chocolate mint and more. But far and away, my favorite is chocolate peanut butter. I love that combination. We do one that’s allergen-free.

Dairy Foods: Let’s look at the basic chocolate milk formula in general and discuss what ingredients are in there and what roles they play.

Miller: An industry standard for the production of chocolate milk consists of 93% milk, 6.3% sugar, 0.65% cocoa powder and 0.05% carrageenan. The final product is usually standardized to either 2% or 1% fat, meaning there’s 2.15% or 1.1% fat in the milk before the addition of the other ingredients.

Milk, of course, provides nutrition and flavor. Cocoa powder — often processed with alkali — provides the chocolate flavor with some of the bitterness removed. Sugar or sugar substitutes provide sweetness. Carrageenan suspends the cocoa powder in the beverage, provides thickness and keeps the ingredients from separating. And if present, dipotassium phosphate is a buffering agent and pH stabilizer, and salt increases the chocolate flavor.

Dairy Foods: The cocoa powder, though not the leading ingredient by weight, is clearly a critical component of chocolate milk. How does a processor choose the right type for the formulation?

Katy Cole, technical service manager, Cargill Cocoa & Chocolate, Lititz, Pa.: It typically comes down to the desired color and flavor profile. It may also vary based on the target market. Kids often prefer a sweeter flavor profile that’s lower in overall cocoa impact, while a product aimed at the adult market might want to provide a stronger, fuller, less-sweet chocolate profile.

That said, most dairy applications use alkalized cocoa powders. The neutral pH of a lightly to moderately alkalized cocoa blends well with dairy. Non-alkalized cocoa powders have acid or astringent flavor profiles that aren’t balanced by the clean, subtle flavor of milk.

So in a kid-friendly chocolate milk, manufacturers will choose a lightly alkalized cocoa powder, or they’ll use less cocoa to deliver a sweeter, less bitter chocolate milk. In protein or sports-style beverages, medium alkalized cocoa powders can help mask the off flavors sometimes associated with protein and other fortifications. These cocoas offer a fuller, more intense cocoa flavor.

Premium milks and shakes might be a place for high-fat cocoa powder. Currently, high-fat cocoa powder is more often used with premium ice cream applications, but it could also deliver a richer, more indulgent premium milk or shake.

Dairy Foods: How should we expect these powders to behave in the product, both in the plant and on the shelf?

Cole: Remember that cocoa doesn’t dissolve like sugar; it needs to be suspended in the matrix. As a result, it’s important to consider the application. For example, in ready-to-drink beverages, particle size plays a critical role, as coarser particles will settle more quickly.

For dry-mix beverages, especially those that’ll be mixed with cold liquids, the wettability of the cocoa powder becomes key. In these applications, we recommend lecithinated cocoa. Lecithin, as an emulsifying agent, functions to reduce the surface tension of the cold milk or water, significantly improving dispersibility so that the powder mix disperses more quickly below the surface. For best results, the finished beverage manufacturer will produce an agglomerated product.

Dairy Foods: This all sounds a little complicated. Can we simplify things?

Miller: Often chocolate milk manufacturers don’t put together their own ingredients, but instead select a company to select one of their powders or syrups to add to the milk. These companies also work with clients to make custom blends, or offer selections of premium-to-basic products. This leaves the selection of the chocolate powders in the hands of the chocolate experts and reduces complexity in the dairy plants.

Dairy Foods: What’s your view, Rick?

Stunek: There are so many cocoa powders available, and our lab could make any of them work in chocolate milk. It’s just that not all of those chocolate milks would be equal. It all boils down to the specific profile and price point you’re looking for. There are really no hard-and-fast rules.

Dairy Foods: And where does process fit into the picture? As a matter of fact, how do we generally process chocolate milk anyway?

Miller: A typical flow process would involve receiving raw milk that would be separated into standardized skim and cream. The chocolate-mix powder is hydrated with the raw skim milk and blended with additional sugar using a liquefier, or high-speed mixer. The required amount of cream is pumped into the milk tank and blended to reach the targeted fat level of the chocolate milk and then agitated.

Chocolate milk is pasteurized at 180F for 15 to 16 seconds at high speed. It exits HTST at 38F to 40F or at the required temperatures and times based on the milk processor’s choice of pasteurization type. It’s homogenized at 2500 psi and filled into bottles or containers ink-jet printed with an expiration date.

While packaged 2% chocolate milk is held under refrigeration at 35F to 40F, ultra-high-temperature, or UHT, processing conditions and aseptic packaging can be used to make a shelf-stable product that requires no refrigeration until after the product is opened.

Dairy Foods: Do the high temperatures affect the finished product’s profile?

Stunek: Any time you subject cocoa to those high temperatures, you’re going to impact its flavor, usually giving it a malty note. The positive is that it tends to mask the cooked note of high-heat white milks.

Dairy Foods: What other qualities should a processor keep an eye on when making chocolate milk?

Cole: Consistency of color and flavor is critical for dairy beverages, as dairy is more sensitive to color and flavor variation compared to other applications such as bakery. Also, good microbiological quality is important.

Dairy Foods: Any other final advice?

Miller: Start with quality ingredients and maintain that quality throughout your process and distribution. Have product specifications and use them. And work with your supplier. They’ve worked on these products before and have a lot of experience that can save you a lot of issues. Learn from their experience.

Stunek: More than anything, decide on what market you’re trying to capture: Are you going after the premium market? Are you trying to appeal to the post-workout market? Moms? Then decide what your market likes. Tastes in chocolate are often regional in nature. And lastly, remember that your company’s name is going on the container.

Dairy Foods: Wise words. Speaking of which, make a pitch for your favorite chocolate dairy drink.

Miller: Chocolate milk, for all the great reasons mentioned above: great taste, refreshment, nutrition and deliciousness.

Stunek: Even though I drink 1% chocolate milk after I run, I’m an aficionado of whole chocolate milk. Not only is it delicious, but it’s also satiating. When I drink even six or eight ounces of whole chocolate milk, I’m full pretty quickly. So that works for me as a way to get calcium, protein, potassium and vitamins while satisfying my appetite. That way I don’t fill up on empty calories.

Krasinski: I like and drink plain-old low-fat chocolate milk. It’s got everything we need — protein for growth, carbohydrates for cellular energy and fats and lipids for cellular reproduction — making it nature’s only true completely balanced nutritional drink.