The pump range consists of four pumps with the following performance data:

- inlet pressure: 50 psi

- capacity: 400 gpm

- head: 400 ft

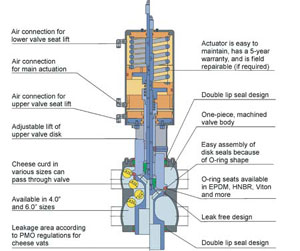

- temperature: up to 250The first-ever Cheese Curd Outlet PMO Mix Proof Valve specifically designed to automate the cheese curd vat transfer process was introduced by Sudmo North America. The company now offers a PMO mix proof valve that can pass particulates up to 1 1⁄2" in size without plugging the valve. This revolutionary new valve greatly simplifies the valving and piping of cheese vat applications and eliminates the cleaning problems associated with block and bleed systems. Sudmo PMO mix proof valves offer many proven advantages including leak-free changeover, a one-piece machined body, maintenance-free actuator, balanced stem, and the latest control technology. There are no special tools required for replacing seals.

Sudmo

SudmoSudmo North America

815/639-0322

www.sudmona.comViking Pump has expanded its gear reducer product line to include a new series of in-line gear reducers compatible with any positive displacement pump or other equipment needing speed reduction. The new gear reducers have the input and output shaft on the same centerline for easy alignment and maximum space savings. All gear reducers in the new series offer double reduction, high efficiency and low noise levels. The gear reducers are available in ten different sizes, with ratios varying from 2.6:1 to 35.1:1. Available horsepower ranges from 0.5 to 350 hp (0.37 to 261 kW), while output speeds range from 50 to 673 rpm (with 1,750 rpm input). The gear reducers offer universal mounting with either a solid input shaft, or a hollow input shaft combined with a NEMA C or IEC flange to close-couple to the motor. The direct mounting eliminates alignment problems as well as the need for a coupling set and a coupling guard between the motor and the reducer. VikingViking is also introducing a Low Flow, High Hygiene Pump. The AccuLobe is the smallest member of Viking Pump's extensive lineup of rotary lobe pumps. Designed for metering, filling and transfer applications, its unique 5-lobe rotors and small 20 ml/rev displacement combines accurate dosing with minimal pulsation. Capacities to 9.2 gpm (32 lpm) and pressures to 220 psi (15 bar) are possible on fluids from 0 to 150,000 cSt viscosity. The AccuLobe's sanitary/hygienic design is suitable for lab, pilot plant and production applications in food, beverage, biotech and pharmaceutical markets. It is 3A-conforming and has been tested and certified according to the EHEDG method for in-place cleanability of food processing equipment. It's low-shear, high viscosity capabilities also make it perfect for process ultrafiltration, creams and lotions, resins and coatings, inks and water treatment polymers. Front-loading seals allow fast and efficient maintenance.

VikingViking is also introducing a Low Flow, High Hygiene Pump. The AccuLobe is the smallest member of Viking Pump's extensive lineup of rotary lobe pumps. Designed for metering, filling and transfer applications, its unique 5-lobe rotors and small 20 ml/rev displacement combines accurate dosing with minimal pulsation. Capacities to 9.2 gpm (32 lpm) and pressures to 220 psi (15 bar) are possible on fluids from 0 to 150,000 cSt viscosity. The AccuLobe's sanitary/hygienic design is suitable for lab, pilot plant and production applications in food, beverage, biotech and pharmaceutical markets. It is 3A-conforming and has been tested and certified according to the EHEDG method for in-place cleanability of food processing equipment. It's low-shear, high viscosity capabilities also make it perfect for process ultrafiltration, creams and lotions, resins and coatings, inks and water treatment polymers. Front-loading seals allow fast and efficient maintenance. Viking

VikingViking Pump

319/266-1741

www.vikingpump.com

APV pumps and valves are among the most hygienic and advanced in the world. Designed and built around the customer's need for hygienic processing, product protection, and fast, easy maintenance. APV pumps and valves are backed by a 100-year track record for technological advances, process knowledge and dependability. The centrifugal pump line manufactured by APV meets 3-A, FDA, USDA, BISSC and more. Major lines include the W+ Series, the most advance, high performance and sanitary pump for the demands of high quality products; and the V2, APV's economical solution to a wide range of pumping needs. APV's broad range of pumps also includes positive displacement pumps such as the DW and R Series. The DW rotary lobe is ultra hygienic and so fast that it can often be both the product and CIP pump. APV's R Series pump line meets 3-A COP requirements and are known for easy disassembly and clean up equaling low maintenance costs. APV's wide range of valves includes a hygienic 3-A single seat design,a cutting-edge control unit,and an ultra-hygienic mix-proof valve designed to leave no surface unclean.APV

800-554-5290

apvproducts.us@invensys.com

Versa-Matic has released its Ultra-Matic 2" high efficiency pump. A completely redesigned air section provides increased pump performance while requiring less compressed air to operate. With a pumping capacity of up to 200 gallons per minute, the Ultra-Matic provides a performance increase of up to 30% compared to other air-operated double diaphragm (AODD) pumps. The Ultra-Matic's performance increase can be attributed to enhanced volumetric efficiency and the ability for compressed air to completely evacuate the pump. The redesigned air section efficiently utilizes space and eliminates friction by way of a patented sliding exhaust valve that enables air to exit directly into the atmosphere. Air flows smoothly through the valve and center section, entering through one port and exiting through another. This design results in streamlined efficiency that saves costly compressed air. In addition, the Ultra-Matic has fewer moving parts, minimizing repair and maintenance-while a positive pressure shifting mechanism eliminates stalling. Available for Versa-Matic's 2" AODD pumps, this industry-changing breakthrough is available in a variety of materials and styles, including plastic, aluminum, cast iron, and stainless steel. The Ultra-Matic is interchangeable with all existing bolted and clamped Versa-Matic pumps, and is retrofittable with Wilden 2" clamped-style pumps. Versa-Matic Pump Company, a unit of IDEX Corporation, is a recognized leader in the design and manufacture of air-operated double diaphragm pumps and accessories.Versa-Matic

724/327-7867

www.versamatic.comA New W75RS PMO Mix Proof Valve from Waukesha Cherry-Burrell, an SPX Proces Equipment Co., is designed to meet criteria of PMO for Grade A dairy processes. It is offered in 1 1⁄2, 2, 2 1⁄2, 3, 4 and 6 inch tube OD sizes. Features include balanced lower plug standard, an external flush option, an independent seat lifting actuator, stem and balance flush options, PTFE guide bearings to support valve stem, standard pressure rating 150 psi, a transparent control top option providing electronic feedback with optional internal solenoid valves, interface options for Asi Field Bus and DeviceNet. Other new products from WCB include a 6" mix proof valve, new Y-Body Valve and a new Rising Stem Valve Sensor. Waukesha

WaukeshaWaukesha Cherry-Burrell/

SPX Process Equipment

262/728-4934

www.spxprocessequipment.comThe high performance FKL Series positive displacement pumps from Fristam Pumps handle pressures up to 300 PSI, viscosity up to one million cps, shear sensitive products and adverse suction conditions. Its improved rotor combined with shaft and bearing innovations allow for lower suction requirements, higher-pressure capabilities and greater efficiency. Applications include cheese curds, cream, ice cream mixes and whey concentrates. Seven models are available. Fristam

FristamFristam Pumps Inc.

800/841-5001

www.fristam.comSidebar: Alfa Laval Gains PMO Compliance for Mix Proof Valves

Pleasant Prairie, Wis.-A "Memoranda of Milk Ordinance Equipment Compliance" ("M-b Letter") was issued by the U. S. FDA Center for Food Safety and Applied Nutrition - Milk Safety Branch, advising Regional Milk Specialists that the Unique PMO Sanitary Mixproof Valve meets the applicable provisions of the Grade ‘A' Pasteurized Milk Ordinance (PMO) when used to separate cleaning product solution and milk and milk products. The memorandum further detailed required construction, installation, and operational requirements for the valve that must be maintained to ensure compliance.The Unique PMO Mixproof Valve is designed for automated dairy operations requiring double-block-and-bleed functionality. It eliminates the need for manual pipe swing connections and/or multiple seat valves, while offering optimum hygiene without o-rings or sliding steel parts. Dome-free upper and lower bodies allow for complete drainage.

The Unique PMO is available in sizes 2", 2.5", 3", and 4". Valves are equipped with the ThinkTop® control and indication unit, providing a flexible control interface with your automation system.