Air Operated Double Diaphragm (AODD) pumps have been part of the industrial pumping scene for more than 50 years. These pumps are extraordinarily good “all-rounders” and

boast vital performance characteristics that make them ideally suited to a wide range of hygienic pumping applications in the dairy industry.

Dairy applications for AODD pumps

AODD pumps are suitable for a host of applications in the dairy industry, including raw materials transfer, drum emptying, recirculation, filling machines, mixing and dosing, processing and sampling. They will readily handle viscous liquids as well as fluids containing soft and hard solids such as fruit puree containing seeds and pips. This versatility makes them well suited to pumping many different fluids such as:

- Yogurts, including various flavorings

- Creamed cottage cheese

- Cream

- Ice cream mix, syrups and toppings, chocolate coatings

- Margarine and fats

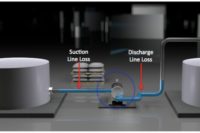

The pumps have large internal clearances and flow-through which prevents clogging, with the size of solid particles that can be pumped related to the pump size. However they also have gentle pumping action which avoids damage to shear sensitive products. The pumps are capable of pumping viscous fluids since the flow rate is directly proportional to the speed of the pump. When viscous materials are pumped there are friction losses within the pump itself and between the fluid and the walls of the pipe supplying the pump. The pump automatically reduces the pumping rate as viscosity increases and at the point where the pump can no longer move the liquid, it simply stops without damaging itself. Typically, AODD pumps can move fluids with viscosities up to 20,000 cps.

Using AODD pumps

Some of the key benefits offered by AODD pumps are that they are self-priming, will run dry without damage and need no electricity. Self-priming means that the pump is capable of drawing up liquid even when installed above the source liquid level and without having to have any liquid in the pump already. This self-priming characteristic means there are few restrictions on physical placement of the pump and also means that by simply attaching a hose to the inlet, the pump can be used as a “scavenger,” to completely empty containers. In addition, if the supply of fluid runs out, the pump will run dry without any damage to it. Most positive displacement and centrifugal pumps fail if they run dry, frequently because their shaft seals or stuffing boxes may require lubrication or cooling from the pumped fluid.

AODD pumps, however, simply run faster when running dry without damage. The pumps are powered entirely from compressed air, and so can be used in applications where electricity is not available or must not be used. The pressure from the compressed air moves the two diaphragms inside the pump. These diaphragms form a dynamic seal that converts the pneumatic pressure on one side to a fluid pressure on the other (the fluid to be pumped). Discharge flow rates can be adjusted simply by controlling the air inlet or the discharge flow, making them extremely simple to use, with no complex control systems needed. AODD pumps are very reliable since they have very few moving parts and components that can wear. They are easily dismantled for maintenance or diaphragm replacement. These factors contribute to a low cost of ownership.

Meeting hygiene standards

AODD pumps used in hygienic applications are manufactured from 316 grade stainless steel, with diaphragms made from sanitary grade elastomers such as Santoprene, Buna-N, Viton and Teflon. The key factors which determine the suitability of a diaphragm for a particular application are: flex life, the composition of the fluids to be pumped and their effect on the diaphragm, the temperature range that the pump must operate in and the abrasive nature of the media being pumped, including the size of any particulates.

The ability to clean the pumps is also of critical importance, and pumps used in the dairy industry will generally have to conform to the requirements of at least one of the following regulatory authorities:

- FDA (Food & Drug Administration)

- 3A Sanitary Standards Administrative Council in the USA

- EHEDG (European Hygienic Equipment Design Group)

- USDA (United States Department of Agriculture)

Cleaning is either carried out by dismantling the pump between batches or carrying out clean–in-place (CIP) procedures. AODD pumps contain fewer moving parts than many other types of pumps and can be easily dismantled for cleaning. Many of the materials used for manufacture will also be resistant to the chemicals used in CIP processes.

Choosing the right pump for the application

With a wide choice of pump materials and, of course, an extensive range of sizes and pumping capacities from a large number of manufacturers, there are pumps to suit a broad range of hygienic production and transfer processes.Given this huge choice, it can be useful to consult with independent pump suppliers, who are not tied to a particular manufacturer, for advice on the most suitable pump for a given application within the allocated budget.

For more information, visit tri-ark.com.

Viton and Teflon are registered trademarks of DuPont

Santoprene is a registered trademark of ExxonMobil