By Relco

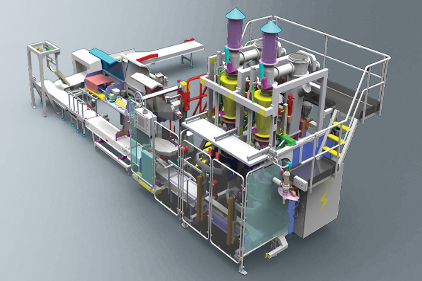

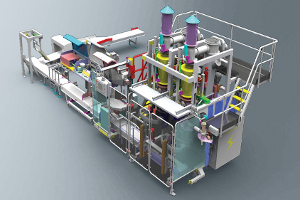

Relco LLC has teamed up with Technopak Limited of New Zealand as the USA distributor to provide their fully automated USDA sanitary bagging lines for dairy and food plants.

The Technopak 25-kilogram bagging lines can achieve speeds ranging from 1 to 10 bags per minute on one common packaging line by use of an innovative modular configuration. The modular components of the system are designed for maximum individual component flexibility and provide opportunity for cost effective upgrades.

The Technopak packaging systems are designed to minimize dust during the bagging operation and achieve repeatable high accuracy final bag weights. All of these packaging systems can be integrated with necessary downstream components to meet the high demands of your customers, such as metal detection, ink jet printing, check weighing, robotic palletizing, stretch wrapping, bag flattening and reject station.

Pre and Post bag powder gassing options can be integrated with the filler heads to achieve extended shelf life for high fat products.

An optional vacuum sampler system provides continuous composite samples using 2 or 3 divert positions for any of the automated packaging lines.

The Relco/Technopak team has the skills, knowledge and experience for all your powder handling and packaging needs.

Relco

320-231-2210