Early in the design stage for a major remodeling of a fluid milk plant in Little Rock, Ark., Turner Holdings, Covington, Tenn., turned to American Conveyor Co., Ubridge, Mass., for design and installation of more than 2,000 feet of new conveyers.

The job included more than 1,000 feet of stainless conveyers and another 1,000 feet of roller conveyers including in-floor pan, kneehigh and elevated cable style conveyors.

The conveyor improvements are just one component in a complete gutting and rebuild of the plant.

"This plant, the former Gold Star dairy plant, is now the flagship plant for Turner-Coleman," says Turner's Operations Manager, Mike Flagg. "Our unflagging commitment to quality means that we gutted this plant remodeling it into a state-of-the-art facility so that we can process milk into the freshest, highest quality dairy products in the marketplace."

Complete conveyor replacement "Only 15 feet of the original table-top or carton conveyor remains of the original layout," says Bruce Macphearson, American Conveyor's midwest sales manager. "Everything else-including conveyors, casers, palletizers, and labelers is all new. We designed and fabricated stainless steel conveyors into an open style frame in the production areas while the overhead was stainless steel fabricated with drains.

The stainless discharge overhead conveyor from the case washer to the three-way divider is cable conveyor which eliminates the need for chain lube in addition to reducing the opportunity that chain provides for contamination - the less moisture in the system the less chance for bacterial growth. The empty corrugated conveyor is also cable and overhead to eliminate the possibility of contamination from foot traffic. All of our design and fabrication took into consideration Flagg's concern for reducing bacterial growth and ease of cleaning."

After washing, the empty cases are conveyed single-file through the storage cooler and palletizing room to the casing area on dual cable overhead stainless conveyor where they are divided into any one of the three casing lines. Stainless Steel loop inverters drop cases from the elevated conveyors to two-foot or knee-high conveyors as they invert cases to open side up for filling.

Empty corrugated cases formed in a separate forming room are dropped on the knee high conveyor at the same location as the plastic cases arriving from the inverter by way of an additional line of stainless dual overhead conveyor.

Reacting to varying customer packaging and inventory requirements Turner's production staff choose to fill either corrugated or plastic cases with the appropriate product including bag-n-box products from the designated filler.

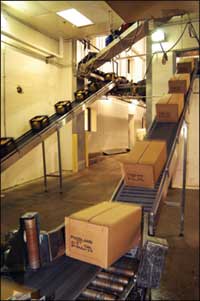

Alternately filled plastic or corrugated cases travel by stainless incline conveyor to an overhead roller conveyor on their way to one of three palletizers where the cases are formed into 3 by 3 square patterns five cases high. Afterward, palletizing loads are stabilized by stretch wrapping for storage and delivery.

"American makes it philosophy real," says Flagg. "We asked for a quote from several different manufacturers - not only was American the first to respond; Bruce Macphearson, their regional sales manager provided a layout and a redesign that would save us money and increase our productivity along with the quote. And when it came time to get it installed Macphearson not only got it done on time he co-managed other vendors to make sure it would all come together when it was supposed to. Lots of companies talk about becoming partners, but American literally became an extension of us until the job was done."