How Gamajet’s impingement cleaning reduced cleaning downtime and improved results for a major dairy plant.

In early 2009, a major dairy cooperative struggled with how to clean a spray dryer transfer duct in a more thorough manner and do so in less time. The plant required a high level of sanitation, especially for one of its main products, baby formula, which was under scrutiny after the previous fall’s massive product recalls for infant formula. At the same time, the industry was dealing with lower prices for its products. Savings and efficiencies were needed.

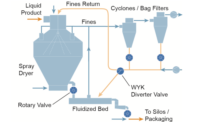

The main spray dryer was designed with a rotary impingement head to clean the main chamber. The transfer ducts to the cyclone had retracting clean-in-place spray heads and sani-midget rotary spray heads to clean the ducts. The spray balls relied on a rinsing action for cleaning and therefore required a significant amount of water and time to clean the ducts. The spray balls did not have sufficient force to remove powder buildup, which required manual scraping.

The cooperative’s plant manager and consulting engineers, Platts Drievap Eng. Ltd, contacted a Gamajet distributor, HD Process NZ Ltd, to see if the rotary impingement cleaning could be used in the transfer ducts. Working as a team, the plant staff, consulting engineers, distributor and Gamajet developed a solution.

The key was the utilization of the Gamajet V, which is media driven and able to fit through the standard 3.5-inch tank opening. The Gamajet projects strong jets of cleaning fluid in a reliable 360° pattern and is sized to accommodate the existing pumps and piping to clean the ducts. A directional unit also was selected for one area where a focused cleaning pattern would save additional time and material.

A trial of Gamajets delivered exceptional expectations. The plant manager was so pleased he applied for budget approval to procure Gamajets for the transfer ducts, with some units being switched to the Gamajet VI to accommodate smaller openings. The team also began investigating other areas, such as the cyclone, to see how Gamajets could improve upon the spray balls. Soon after, the engineering consultants recommended the Gamajets for duct cleaning at a similar plant in a different country.

Written by Michael Delaney (Gamajet Cleaning Systems, Exton, Pa.) and David Hamlin (HD

Process NZ Ltd., Auckland, New Zealand).

For more information, contact Gamajet at www.gamajet.com or 877/426-2538.

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing