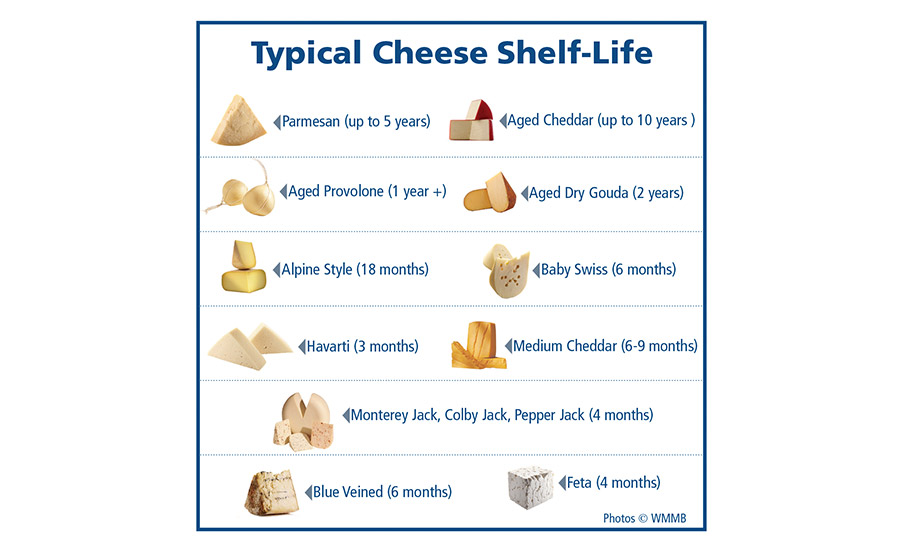

The shelf life of cheese can vary from a few weeks to multiple years depending on its composition and how it is packaged. In general, high moisture cheese varieties have a shelf life of only a few weeks, although processing innovations, such as hot-pack cream cheese can extend this. Low-moisture, hard cheeses (like Parmesan) have a shelf life that can range from 10 months to several years. The accompanying table outlines some other examples. So, while the type of cheese has the greatest impact on shelf life, two factors limit a cheese’s shelf life potential: development of microbial-related defects and deterioration of the expected texture/flavor.

In order to extend the shelf life of a cheese, it’s important to first have a clear understanding of the issues that affect the product’s viability. Of course, starting with high-quality milk is paramount in manufacturing a product that retains its quality on the shelf. Outside of that, however, each concern requires a slightly different solution. By determining the area of concern, you will be better able to find a solution and extend your cheese’s shelf life.

Avoiding mold and yeast growth

The first area of concern for many cheese manufacturers is the growth of yeast and mold. The first step in containing this is to reduce cheese contamination by yeast and mold, which involves careful control of process equipment sanitation as well as excellent air quality in the manufacturing and packaging environment. Vacuum packaging of cheese (blocks and chunks) is commonly used to remove oxygen and inhibit the growth of yeast and mold. Modified atmosphere packaging, or gas flushing, is used for shreds or slices where oxygen is replaced with other gases including carbon dioxide, which is inhibitory to various spoilage microorganisms. Some cheeses respire during ripening so they require permeable packaging to avoid blowing. Natamycin is also commonly used in shredded cheese as an antimicrobial agent that is effective against yeast and molds, and is also not influenced by pH. Additionally, sorbate and propionates are used as mold inhibitors in several types of cheese.

It’s also worth noting that while many of the solutions listed above have been used regularly for many years, consumers are becoming interested in clean labels, i.e. cheese without added preservatives. For this reason, new technologies, like high-pressure processing (HPP) and pulsed-light treatment, are being explored as approaches to inactivate spoilage microorganisms in packaged cheese or to decontaminate the surface of cheese without the use of additives. There is also interest in using natural food preservatives (antimicrobials), such as essential oils from certain plants or microbial fermentates.

Avoiding texture, off-flavors issues

Deterioration of the cheese texture can also damage a cheese’s viability. This is especially true for higher-moisture cheeses like Mozzarella that can soften significantly over time. Strategies for slowing down these textural changes in cheeses include the use of less proteolytic rennets, higher curd-stretching temperatures and low storage temperatures. A third limiting factor to shelf life is the development of off-flavors during ripening. Strategies for reducing the risks of developing these unwanted off-flavors include use of high-quality milk and milk products, careful selection of ingredients (type of starter culture, adjunct and rennet) and a reduction in contamination by undesirable microorganisms.

Finally, it’s important to discuss how shelf life can be affected by the distribution chain. Mold, yeast and microbial contaminants are not the only things that affect the texture and flavor of the cheese. Intense lighting, warm temperatures (which can cause the cheese to sweat) and compromised packaging can all lead to a decreased shelf life or inferior product. For many types of semi-hard/hard cheeses, retailers are looking for a shelf life of between five to six months, which requires a cheese to be free from any microbial contamination that might contribute to the deterioration of shelf life.

Thanks to recent innovations, it’s becoming easier to extend shelf life and avoid the development of microbial-related defects and deterioration of the expected texture/flavor. Ongoing research is continually looking for new technologies that improve and extend shelf life, but such research needs to be supported in order to ensure that these technologies are available. Thankfully, current innovations offer a number of solutions, and such research has provided cheesemakers with a range of safe and effective methods for extending shelf life.