OYSTAR

Oystar’s fully servo-controlled Flexline FL 8/8 CA aseptically fills and seals preformed cups with dairy products. All movements are servo-controlled, meaning changes in filling curves or quantities can be controlled from the control panel and saved as dispensing formulas for future runs. The Flexline achieves a production rate of up to 38,400 cups per hour; its filling quantity range is 90 to 400 grams. The machine has three different dosing devices, providing maximum product flexibility. All dosing equipment is designed for CIP/SIP treatment.

732-343-7600; www.oystar-group.com

ARCIL

The fillers and nozzle plates installed on the form-fill-seal machines by Arcil and manufactured by its Dosil division have obtained the RPSCQC qualification which allows their U.S. customers to comply with current food standards in the United States.

513-508-8692; www.arcil.fr

DARIFILL

DariFill released another system that increases ice cream novelty production speed and efficiency. The Pegasus II sandwich filler produces ice cream sandwiches at over 200 per minute. The companion cartoner collates six packs (or larger packs) at 200 per minute as well. The system eliminates many operator adjustments with recipe-driven setup and increases uptime and throughput. DariFill also provides filling solutions for cups (3-ounce through quarts) and cones (flat-top and ball-top).

614-890-3274; www.DariFill.com

ELOPAK

Elopak’s S-PM240 high-speed filler for Pure-Pak gable-top mini cartons has an operating efficiency of 95%. With an output of 400 cartons per minute, the S-PM240 is ideal for school milk programs. Servo motor operation helps achieve high speeds with just two lines, and easy access for maintenance. Controls are user-friendly, including automatic carton size changes. The system has a footprint of less than 200 square feet. Options include spray sanitizing, automatic CIP adapter and HEPA filtration.

248-705-3159; www.elopak.com

FEDERAL

Federal has refined AcuFill hygienic net weight filling technology. A new load cell interface controller eliminates a previously required on-board computer. These robust controllers offer multiple stage filling, Ethernet communication, advanced diagnostics and a load cell calibration utility that is integrated into the filler’s operator interface. For dairy and beverage use, sanitary 3-A certified models are available and designed to meet stringent hygienic requirements to protect product quality and provide maximum shelf life.

414-384-3200; www.FederalMfg.com

FOGG FILLER

Fogg’s semi-automatic one-way recovery trough allows cleaning of the valves in place without adding or removing any hardware. It also makes flavor changes easy, which helps decrease the amount of cleaning time and operator contact with the filling environment to increase sanitation. The HEPA filtration system filters the filling environment to class 100 HEPA air. This gives a level of confidence knowing that there are no airborne contaminates in the filling environment.

616-786-3644; www.foggfiller.com

HINDS-BOCK

Hinds-Bock parfait cup line includes an automatic cup de-nester, indexing platen conveyor, automatic filling machine and cup kick out system with accumulator table. Other options are available, such as dry ingredient depositor for granola, linear net weight scale for fruit and automatic lidding system. Single lane systems typically run 30 per minute, faster for multiple lane systems. It can be used for yogurt and dessert parfait cups.

877-292-5715; www.hinds-bock.com

GRAM EQUIPMENT

The bottom-up filler from Gram Equipment makes it possible to fill molds on stick novelty machines with ice cream down to -5.5 degrees C (22 degrees F). This improves the ice cream texture and makes it possible to increase the overrun. The filler can be mounted on any molded stick novelty machine. Different inclusion types can be added to the ice cream, and due to the high viscosity of the ice cream the inclusions are uniformly distributed in the product. The filling cycle movement is servo-driven to ensure filling of stiff ice cream without air pockets. The filler is equipped with a sucking back system that leaves only a very small ice cream tail.

813-248-1978; www.gram-equipment.com

NIMCO

Nimco Corp. introduced its Model 5110ELCP, a single line double index gable-top packaging machine designed with a CAP-PAC rotary spout applicator for liquid food and beverage markets. It has fill volumes of 4 to 16 ounces (120 to 500 milliliters). The mechanical drive provides repeatable accurate performance while easy to maintain and operate. Electronic controls for the fill system allow for infinite fill adjustments for accurate and consistent fill weights.

815-459-4200; www.nimco.com

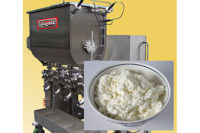

REISER

Reiser and Vemag have designed a variety of dripless valve cheese cup filling systems for all types of applications and production requirements. This cup filling solution combines a Vemag portioner with a dripless valve filling attachment. It’s an ideal solution for depositing precise portions of product and can be easily integrated into existing production lines. Use it to deposit processed cheese, cheese spreads and cheese dips into cups, tubs, trays and packages.

781-821-1290; www.reiser.com

OSGOOD

Osgood Industries recently introduced the multipack filler for pre-formed containers. This compact and flexible machine has a small footprint and is designed to exact the volumetric filling of liquid or viscous products into both preformed cluster type and single cup containers, on the same machine. Multiple lanes deliver format flexibility and sequential carrier plates allow quick change between formats. The fillers are optimized for several applications, including yogurt and other cultured dairy products.

813-792-4547; www.osgoodinc.com

SCHOLLE

The Scholle SureFill combines advanced bag-in-box filling technologies in an operations-friendly machine with the ability to fill fresh, extended shelf life and high-acid products with a single machine. This filler provides a solution to an unmet market need with a high-volume production line that allows dairy manufacturers the ability to offer 100% preservative-free, aseptic products. The system features a unique peroxide vapor sterilization process that ensures a wide range of fitment options. Dairy tubes are kept sterile throughout the aseptic filling process.

708-836-3641; www.scholle.com

WCB ICE CREAM

WCB Ice Cream has engineered a new type of filler for the rotary universal filler. The new filler increases the product that can be produced with the equipment. The cup spinner has been fine-tuned. The kit consists of a servo motor with gears and a lever to move the filler up and down instead of a traditional mechanical CAM movement. The servo filler is ideal for extrusion and special fills where every movement is unique for the task. It also gives a more dynamic movement of the filling unit which gives a better distribution of ice cream in products.

201-784-1101; www.wcbicecream.com

SERAC

Serac’s Combox H2F is a combination blow molding, filling and capping solution for the dairy market. The unit is specifically designed for dairy bottle production below 12,000 bottles per hour. Manufacturers can blow mold bottles in-house. Serac focused on incorporating the company’s latest aseptic filling innovations and cost control into the Combox. The result is a fully integrated solution which includes the H2F (Highly Hygienic) filler and meets the hygiene requirements of cold chain dairy products.

630-517-5601; www.serac-usa.com

STANPAC

Stanpac developed a Flex E Fill new lidding system for tamper evident non-round lids. The lid applicator attaches directly to the ice cream filler which saves floor space in the filling room and is convenient for operators. The one-piece application is simple compared to the multiple stages and equipment required for other methods of tamper evidence, such as neck bands and inner seals.

905-957-3326; www.stanpacnet.com

SIDEL

Beverage manufacturers can benefit from aseptic technology for smaller production runs with the launch of a new low-output integrated aseptic blow-fill-cap solution from Sidel. The Combi Predis/Capdis FMa has a standard output of 12,000 bottles per hour (bph) for a 1 liter bottle. It can accommodate high- and low-acid products packaged in all common bottle volumes required by the market, between 0.2 liters and 2 liters, with outputs of up to 16,000 bph.

678-221-3000; www.sidel.com

UNIFILLER

The Unifiller hopper topper is a unique product transfer system that is specifically designed as an innovative solution to the many challenges faced by food producers today, including eliminating fluctuating deposit weights. It’s equipped with an optic product sensor and can maintain precise hopper levels. It also includes a flow control to adjust pump speed for different types of products. The machine can pump products like cream, yogurt, sour cream and soft flowable cheese.

888-733-8444; www.unifiller.com

TD SAWVEL

TD Sawvel upgraded many of its most popular machines to exceed 3-A/USDA sanitary standards. All Sawvel models ending in AAA are built to meet or exceed 3-A standards. Key features include: scale controlled filling with high-sample rate provides accurate weight control; alternating side- by-side configuration with continuous product flow; and speeds to 12 containers per minute (with optional discharge conveyor).

877-488-1816; www.tdsawvel.com

EVERGREEN PACKAGING

Evergreen Packaging Equipment offers the EQ-70 gable top packaging machine, a global ESL machine for refrigerated dairy, juice and other liquid food markets. ESL components include a self-contained CIP/SIP system, HEPA filtration, auto-sanitization, carton decontamination and a hermetic filling system to maintain product quality. It has fill volumes of 6- to 32 ounces (180 milleters to 1 liter), the EQ-70 fills liters up to 7,000 cartons per hour (cph) and fractionals up to 9,000 cph.

319-399-3200; www.evergreenpackaging.com