By Sidel

Sidel, the international supplier of liquid packaging solutions to the drinks industry, has introduced Sidel Matrix - its radical, new modular generation of PET bottling equipment. Sidel Matrix is a broad, proven and upgradeable system that is simply the company’s most powerful solution yet in terms of performance, flexibility, cost savings and sustainability. It ensures product safety and quality with a very high standard of hygiene. It features optimally proportioned equipment configured to provide increased production capacity for various beverages - to meet the growing demand in world consumption.

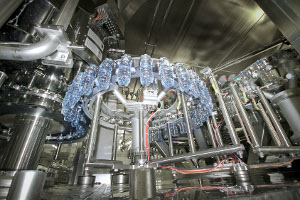

|

| Sidel Matrix filler |

Built on a hygienic concept, Sidel Matrix is fully compliant with hygiene design standards and offers significant advances in terms of simplicity of operation. It provides flexible, ergonomic and efficient production with optimum productivity and reduced maintenance. It promises cost-effective, sustainable production in an environmentally friendly solution, with the potential to lower energy and material usage. Employing the latest proven technologies and large-configuration possibilities, it also makes it possible to match individual production needs more closely. In short, Sidel Matrix offers the drinks industry excellent beverage safety and package quality, as well as lower operating costs and an improved environmental footprint to help succeed in today’s competitive marketplace.

Including blowers, fillers, Combi and labellers, the new Sidel Matrix system is more than just a new product range: it revolutionises the contribution to PET line performance. Designed to be future-proof, the Sidel Matrix system is able to integrate changes brought about by technological and market developments, with several options and upgrades already available to suit changing needs.

The Sidel Matrix blower

Sidel has over 50 years of blow-moulding expertise with more than 5,600 blowers installed worldwide. With the new Sidel Matrix blowers, the company introduces one of the widest portfolios of blow-moulders on the market.

The Sidel Matrix blower ensures excellent production efficiency and can produce as many as 2,250 high quality bottles per mould per hour. It has a modular architecture that enables easy and flexible configurability. With three times more configurations, it surpasses current industry standards and can be easily adapted to individual beverage industry requirements. Three sizes of blowing station make it possible to produce many different bottle shapes, in sizes ranging from 0.1 litres to 3.5 litres. Increased heating yield in the Ecoven and electrical stretching provide a better material distribution and a more consistent process to ensure package integrity and consistency. In the blowing process, unique neck protection, combined with an embedded intelligence for bottle quality control and self-regulation, minimise the standard deviation of the bottle blown, automatically reducing scrap.

Easy to operate, the Sidel Matrix blower benefits from quick and easy assisted mould changeover between formats: less than 15 minutes bottle-to-bottle by a single operator with Sidel’s Bottle Switch system on a 20-cavity machine. Downtime and manual labour costs are therefore reduced and ultimately more bottles are produced in less time.

Requiring fewer heating modules and lamps, the installed Ecoven reduces preform-heating time and cuts electrical consumption by up to 45% while maintaining a very high process capability. Savings on compressed air consumption can reach up to 35% compared with previous Sidel generations. Built with grease-free components and fewer mechanical parts, the Sidel Matrix blower requires significantly less maintenance.

Sidel Matrix fillers

The Sidel Matrix fillers have been designed with a particular focus on hygiene for both still and carbonated beverages. Quality of production is achieved through various features such as a reduced enclosure for better control of the filling environment, which can be operated under a positive overall pressure to avoid contamination from external sources. Additionally, integrated electro-pneumatic components, the absence of vertical movement of the bottles, no ring bowl or carousel and no contact between bottle and filling valve for still beverages eliminate the risk of cross-contamination. There are two filling valve alternatives: the proven Sidel magnetic flow-meter or Sidel’s new flow-meter Vortex valve dedicated to filling pure water with low conductivity.

Utilising the expertise and experience gained in manufacturing previous generations of machines, the Sidel Matrix fillers are robust yet ideally sized to offer optimal performance. With each module going through intensive testing far beyond the conditions under which they will be operating, they are designed to have an extended working life. Each is operated by brushless motors to reduce the number of mechanical components requiring maintenance. The well-defined module interfaces contribute to easily handle various types of beverages, whatever the recipe or bottle format. With neck bottle handling by gripper, format changeovers are very fast, with the option of fully automatic changeover to achieve greater productivity and greater overall equipment efficiency (OEE).

Integrating mixing and filling processes into one system (Blendfill configuration) minimises product loss when switching production between different beverages. Improved cleaning technology also significantly reduces water and chemical use. Savings in electricity consumption of as much as 30% are also possible as a result of the use of servomotors.

The Sidel Matrix Combi

Bringing together all the benefits of Sidel’s Matrix blowing and filling innovation into one high-impact solution, the fully integrated, Sidel Matrix Combi blow-fill-cap solution improves hygiene whilst simultaneously cutting costs to bottle still or carbonated beverages. Based on the same principles as earlier models, the Sidel Matrix Combi has a single, hygienic enclosure with no intermediate equipment.

Its overall efficiency, compact size, ergonomic design, easy operation and maintenance - along with its low consumption of energy and materials - all contribute to lower production costs. With improved commonality between the blowing and filling functions and a single operator interface to improve ergonomics, the Sidel Matrix Combi is more easily controlled, with better overall performance, less need for manual servicing and far greater flexibility. The homogeneous maintenance plan results in increased uptime and aligned documentation simplifies the entire maintenance process.

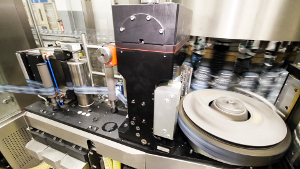

|

| Sidel Matrix labeler |

Sidel Matrix Rollfed labeler

Rollfed is the first Sidel Matrix labelling solution. It allows customers to produce bottles with labels at a reasonable cost, offering the possibility to use labels that are one-third thinner. Although based on the most common labelling technology on the market, it has innovative features that make it possible to optimise performance by speeding up the application of labels and cutting costs on everything, from materials to maintenance.

Sidel Matrix Rollfed uses direct-drive technology to replace gearboxes and mechanical transmission. This complete motorisation of all the axes means highly reduced maintenance and a reduction in energy consumption of up to 30%. Having fewer moving parts connected directly to the motor results in fewer breakdowns and a longer operational life. As every labelling module is directly managed with individually driven motorisation, this contributes to faster format changeovers, offering more flexibility to manage a larger range of format configurations. It is capable of handling bottle diameters from 45 to 160 mm and managing different types of materials and ultra-lightweight bottles.

All vital areas of the layout are accessible should any kind of intervention become necessary and simpler changeovers reduce the risk of injury. Instead of a table that connects all three main elements – labelling station, carousel and infeed/outfeed handling – the system features an individual structure for each process, eliminating the respective maintenance. The maintenance required on the labellers has therefore been reduced by approximately 40%. Quick installation and ease of upgrading is possible since all main modules can be replaced without dismantling the unit.

Proactive Innovation

Sidel Matrix has been launched to meet the challenges faced by today’s beverage producers. It ensures the all important integrity and quality of products and their packaging, doing so with a lower total cost of ownership (TCO) in an increasingly competitive market. It also offers the flexibility to boost production capacity as required, with greater opportunities to accommodate new recipes, packaging shapes and formats, all in a system which minimises environmental impact.

About Sidel

Sidel is the leading global provider of PET solutions for liquid packaging. We are also a driving force for glass and can solutions. We are committed to being the most innovative, responsive and reliable partner, providing sustainable solutions for the beverage industry.

Headquartered in Switzerland, we have production sites in 13 countries and 30,000 machines installed in more than 190 nations worldwide. With over 5,000 employees worldwide, we provide optimal PET, glass and can packaging solutions for water, soft drinks, milk, sensitive products, edible oils and alcoholic beverages including beer.

We aim to create value for our customers by giving them A Better Match. This is the tailored solution that caters to their needs exactly. We do this by offering flexible and reliable production systems that are easily adaptable to market developments and future technology, supported by value-added services. Find out more at www.sidel.com.

SOURCE: Sidel