By Ross

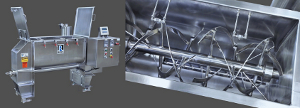

Following its largest inventory expansion to date, Charles Ross & Son Company announced that over 80 Ribbon Blenders, sized for different working volumes and bulk densities, are now available from stock. Most standard and sanitary models can ship within two weeks or less. Built-to-order custom units are also offered with fast lead times like the pictured 10-cubic-feet. Sanitary Ribbon Blender featuring 150-grit stainless steel 316 internal and external surfaces, bottom discharge extruder, lantern rings, spray bar system with atomizing nozzles, load cells and a NEMA 4X Ross SysCon Control Panel.

Following its largest inventory expansion to date, Charles Ross & Son Company announced that over 80 Ribbon Blenders, sized for different working volumes and bulk densities, are now available from stock. Most standard and sanitary models can ship within two weeks or less. Built-to-order custom units are also offered with fast lead times like the pictured 10-cubic-feet. Sanitary Ribbon Blender featuring 150-grit stainless steel 316 internal and external surfaces, bottom discharge extruder, lantern rings, spray bar system with atomizing nozzles, load cells and a NEMA 4X Ross SysCon Control Panel.

Ribbon Blenders are commonly used for rapid blending of dry powders, granules, pellets and other solid forms. These machines also mix paste-like materials, wet granulations and solid-liquid suspensions. Batch components are blended within a U-shaped trough via a horizontal agitator consisting of inner and outer helical ribbons. The ribbons are precisely pitched to move materials in a well-balanced axial and radial flow pattern. Tightly controlled clearances between the trough surfaces and agitator tips further ensure fast and thorough mixing.

All Ross Ribbon Blenders are directly driven by an inverter-ready gearmotor. Compared to belt- and chain-driven designs which suffer from losses in horsepower and efficiency through slippage, direct-drive Ribbon Blenders are more reliable, delivering better performance and requiring less maintenance. Users benefit from electronic speed control, soft-start capabilities and overload protection. For more information, visit www.mixers.com.

To speak with a blending specialist about your application or to inquire about our Trial/Rental Program call 1-800-243-7677.

SOURCE: Ross