By Mettler Toledo

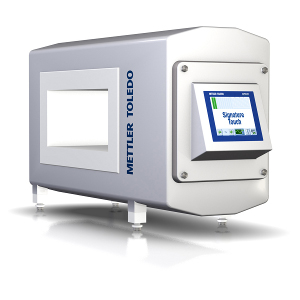

Featuring a full-color touch screen, membrane key panel and product inspection data collection capability, the Mettler Toledo Signature metal detector is designed for cost-effective easy integration into food production lines. When Signature is combined with material handling systems such as conveyors, product inspection can be fully automated.

Featuring a full-color touch screen, membrane key panel and product inspection data collection capability, the Mettler Toledo Signature metal detector is designed for cost-effective easy integration into food production lines. When Signature is combined with material handling systems such as conveyors, product inspection can be fully automated.

Signature Detectors can be integrated with a wide range of standard or custom conveyor systems, enabling automated on-line inspection. Designed to perform and be maintained in a variety of food manufacturing environments, Signature Detectors are available in a variety of sizes, finishes and sealing standards. They can readily detect even the most difficult to detect non-magnetic stainless steels and non-spherical fine wire contaminants.

An optional sophisticated, yet simple, set-up routine allows end users to configure Per-formance Validation Routine (PVR) testing to their own needs. Users can choose to test on a time base or pack count basis. The screen will change to the PVR screen automatically when the testing is due or overdue. Operating in conjunction with a Reject Confirmation Unit (RCU), the system provides the security and reliability to meet all Global Food Safety Initiative (GFSI) standards.

With a proven range of features, Signature metal detectors support your business by providing a strong platform from which you can deliver greater levels of metal detection. A stable and sensitive system, easy to operate, maintain and integrate into your food production line, Signature metal detectors will reduce operating costs, increase productivity and improve competitiveness.

About Mettler-Toledo Safeline

Mettler-Toledo Safeline is a division of Mettler-Toledo, Inc., a global supplier of precision in-struments with sales and service locations in 37 countries. The Mettler-Toledo Product Inspec-tion Group, consisting of CI-Vision, Hi-Speed and Safeline, is the world’s leading supplier of machine vision systems, in-line checkweighers, metal detectors, and x-ray inspection systems. These systems are used in many industries, including food, beverage, pharmaceutical, nutraceutical, personal care, plastics and chemicals to continuously ensure the quality of their products and improve the efficiency of their manufacturing and packaging processes.

SOURCE: Mettler-Toledo