By Standard-Knapp

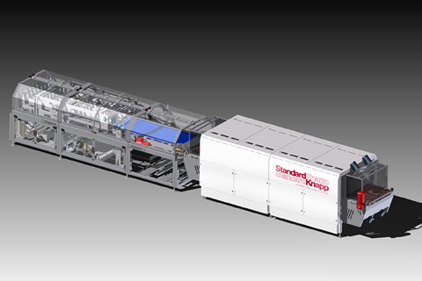

Standard-Knapp, a worldwide leader in the manufacture of innovative packaging machinery, introduces the Tritium Multipacker, a continuous motion multi-packer capable of handling applications in the food, beverage and personal care industries. With single, double and three lane configurations, the Tritium Multipacker swiftly arranges products into compact pack patterns and wraps the configurations in film, thereby eliminating the need for trays and pads. The Multipacker then sends the packs through an energy-efficient heat tunnel to tightly shrink the film around each multi-pack producing a consistent, wrinkle-free bull’s eye and bottom seal.

Standard-Knapp, a worldwide leader in the manufacture of innovative packaging machinery, introduces the Tritium Multipacker, a continuous motion multi-packer capable of handling applications in the food, beverage and personal care industries. With single, double and three lane configurations, the Tritium Multipacker swiftly arranges products into compact pack patterns and wraps the configurations in film, thereby eliminating the need for trays and pads. The Multipacker then sends the packs through an energy-efficient heat tunnel to tightly shrink the film around each multi-pack producing a consistent, wrinkle-free bull’s eye and bottom seal.

In response to the increasing industry pressure toward sustainability, the Tritium Multipacker boasts a lower carbon footprint than competing multipackers. Thanks to its energy efficient heat tunnel, and a reduced amount of overall packaging material used, customers can now experience a greener, more cost-efficient packaging process.

Standard-Knapp’s modularly constructed, stainless steel multipacker is flexible and adaptable, and comes equipped with easy-access “gull wing” guard doors. These transparent, safety-interlock guard doors provide a clear view of all moving belts and chains, enabling “walk-by-maintenance” by maintenance personnel. The Tritium Multipacker features both an innovative Robo-Wand wrapping section and precise servo-driven film cutting system. These features allow for wide product range capabilities, as well as increased speed and reliability. To facilitate machine maintenance, many steel chains have been replaced with timing belts which require no lubrication and create a quieter machine.

In response to customers’ requests for a more easily accessible film feed, Standard-Knapp has designed the Tritium series to include a pull-out film feed module. Operators can now quickly pull the film feed out on rollers for convenient inspection and maintenance.

Printed or registered film is used to wrap each multi-pack, which provides a larger area for product information and allows retailers to stock their shelves faster and with less waste. A company's marketing message can now be printed on the translucent film to promote the cost-saving multi-pack purchase.

The Tritium Multipacker comes equipped with Standard-Knapp’s innovative Operator Interface, as well as the Zero-Gap II Infeed. The Operator Interface utilizes color touch-screen technology to offer a new level of intuitive machine control. Through computer-aided fault recovery, the Operator Interface reduces Mean Time to Recover (MTR) and increases efficiency for a broad range of challenging 24/7 applications. Zero-Gap II Infeed employs electronic sensors to monitor and control product movement, maintaining a constant low line pressure and maximizing machine uptime.

About Standard-Knapp

Standard-Knapp is the leading manufacturer of innovative packing machinery for a variety of industries including beverage, food, household chemicals, personal care and automotive. A pioneer in the field of automatic packaging equipment, Standard-Knapp provides robust, efficient packaging solutions such as tray packers, tray loading machines, case packers, shrink wrappers and bottle packers. With over 100 years of experience, Standard-Knapp continues its tradition of “making packing easy.” For more information on Standard-Knapp’s products, call 860-342-1100 or email info@standard-knapp.com.

SOURCE: Standard-Knapp