By Fogg Filler

Fogg Filler, Holland, Mich., a market leader in the design and manufacture of rotary filling systems for the liquids industry, is taking another step to extend shelf life by improving the design of its F6.2 filler bowl.

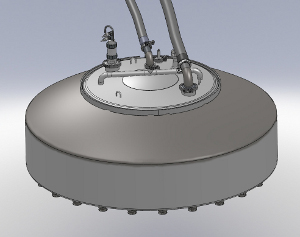

Fogg Filler, Holland, Mich., a market leader in the design and manufacture of rotary filling systems for the liquids industry, is taking another step to extend shelf life by improving the design of its F6.2 filler bowl.

The new filler bowl creates a higher level of sanitation to extend a product’s shelf life. The new design makes the machine very user friendly and eliminates several parts, ultimately lowering the cost of operations.

The improved filler bowl design has eliminated the need for hand cleaning of the upper bowl gasket. By eliminating the second layer of the lid there is no longer an o-ring that needs to be hand washed. The bowl now has a sleek, smooth, design similar to the F4.1, F8 and F9 filler bowls. This design will also greatly reduce condensation that escaped from these o-rings keeping the outside of the bowl clean.

About Fogg Filler

Fogg’s proven Extended Shelf Life (ESL) technologies help lower operating costs and provides the highest level of reliability for your production lines. For more information on Fogg’s new F6.2 filler bowl or for a full line of filling machines and accessories please contact the sales team at 616-786-FOGG or www.foggfiller.com.

SOURCE: Fogg Filler