Product Development Editor

The food safety testing market continues to evolve in response to advanced technologies, improved communications, new regulations and, of course, increased distribution, including shelf-life demands. These factors are shifting priorities for U.S. food producers and altering the competitive landscape for food diagnostic testing companies.

According to a new report from Strategic Consulting Inc. (SCI), Woodstock, Vt., in 2010, 213.2 million microbiology tests were collected in the U.S. food processing industry, a 14.4% increase since 2008. The report is based on SCI’s primary research with more than 100 food processing plants in the meat, dairy, fruit/vegetable and processed food segments. SCI also contacted many of the senior quality and food safety officers at the Top 30 food companies in order to include both strategic and operational perspectives on microbial testing in the U.S. food processing industry.

“After a decade of solid but quiet growth, the microbiology testing requirements of the food processing industry - especially in pathogen testing - have been thrust into the public spotlight again, driving healthy growth in food diagnostic testing,” says Thomas Weschler, president and the report’s author. “Overall market value growth has averaged 13% over the past three years and pathogen testing market value growth has averaged 18% during the same time.”

U.S. food producers routinely conduct microbiology testing of raw materials, the food production plant and finished food products to look for indicators of micro-organisms in the food and/or processing facility. The volume of these routine/indicator tests went up by a little more than 10% between 2008 and 2010. During that same three-year period, however, the volume of tests looking for specific pathogens increased by more than 30%.

“While food companies continue to make investments in their overall food safety programs, new regulations, outbreaks and public concern drive even more pathogen-specific testing,” Weschler explains. “Pathogens are everyone’s focus.” As a result, Weschler says, new diagnostic technologies and new players are entering the market, and the business landscape continues to change through acquisitions, partnerships and new product offerings.

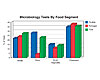

The report states that the dairy industry conducted more than one fourth (28%) of the 166.9 million routine microbiological tests run in 2010, more than the meat and produce businesses. Yet, dairy processors conducted the least number of pathogen tests, a mere 4% of the 46.2 million tests run in 2010. (See chart on page 28.)

“The dairy industry tests for pathogens, but not at the frequency that other food processors do, where pathogens are a greater threat,” Weschler says. “The dairy industry runs ample routine microbiology tests before and after pasteurization to ensure safety. And they are doing a great job.”

Indeed, product recalls due to microbial contamination have been few and far between for the dairy industry. This is something to be grateful for, as well as commended. Having the right tools (lab tests) is important, but it takes a unique person to run an efficient lab.

“A person that is in charge of an in-house laboratory in the dairy business must be a regulatory specialist, laboratory specialist and an excellent manager,” explains James Cook, food safety technologist, SGS Consumer Testing Co., a Swiss company with U.S. headquarters in Rutherford, N.J. “There is a great deal of testing that needs to be performed by the in-house laboratory. They can be grouped into the following areas: regulatory required; food safety; standardization of chemicals, ingredients, batches, etc.; calibration; certification; validation; quality testing such as performance, sensory, physical evaluations, etc.; and microorganism testing.”

Most dairies also work closely with ISO 17025 (the main standard used by testing and calibration labs) third-party laboratories.

“We have learned that establishing proper procedures, programs and continuous training from the beginning is essential in establishing any testing program,” says Cook. “All ISO 17025 laboratories have the knowledge of establishing, maintaining and continuously improving on laboratory testing in order to maintain accuracy and efficiency. No laboratory and personnel can do this on their own. It is essential to work with organizations and other enterprises that allow you to learn from each other regarding the best practices that can be performed.

“Attending conferences and learning from those in other fields can aid a program,” he adds. “If there is a series of laboratories connected, then an internal proficiency testing program can be started. If not, the laboratory should be involved in an external proficiency testing program. This is necessary to determine if testing is consistent and repeatable.”

What can we learn from the European outbreak?

The recent Escherichia coli 0104:H4 outbreak in Europe has all types of food processors re-evaluating their lab testing protocol to make sure they are conducting enough of the proper tests.

“There are a number of lessons that U.S. dairy processors can learn from the E. coli O104:H4 outbreak. For example, it is possible that at any time new or different strains of micro-organisms can create illness in people and cause major outbreaks,” says Cook. “Thus, it is essential to perform trends analysis on indicator organisms to monitor any changes that are taking place in raw materials and operations. Once changes are noted, investigation into the root cause of the issue must be performed in order to take proper corrective action.

“Additionally, accuracy and diligence of testing is not something that can be ignored,” he adds. “Each load, lot or batch, as validated by your program or as required by regulation, must be accurately and timely tested for the parameters required to maintain food safety and quality.”

Dairy processors must also know all about their raw materials. Traceability is imperative.

“While the dairy industry does an excellent job of monitoring incoming milk and milk products, the other ingredients require the same type of testing diligence. Knowledge of the companies or farms producing these materials must not be neglected,” says Cook. “If something happens within the process chain, there is the need for all materials to be able to be traced - from farm to table. A traceability system must be tested periodically to assure that all materials can be traced throughout the entire process chain.”