Technology Solves Challenges: Ultra Dairy meets specific requirements with marking and coding solutions

By Sascha Benke, director of vertical marketing, food, Videojet Technologies Inc.

Since 1933, Byrne Dairy has specialized in delivering high-quality dairy products to its customers - and the family-owned company’s commitment to quality has driven it to develop a product line that includes delicious ice cream, milk, butter and cheese. Byrne Dairy products are available through retail food stores, supermarkets and its own chain of neighborhood Byrne Dairy stores.

In 2004, Byrne Dairy opened a 40,000 square foot ultra pasteurization manufacturing facility called Ultra Dairy to specialize in extended shelf life (ESL) products such as half-and-half, and light and heavy creams. Today, the Ultra Dairy plant can produce aseptic milk and dairy products that do not require refrigeration, expanding the range of products Byrne Dairy can offer its customers and allowing the company to develop solutions with longer shelf lives for restaurants, businesses and household consumers.

Some of the products developed by Ultra Dairy can have shelf lives as long as 170 days. Ultra Dairy produces products for Byrne Dairy, as well as private label products for nationally branded, large retail companies. With the variety of products, shelf lives and brands processed by Ultra Dairy, the company relies on variable data marking and coding equipment to print expiration dates, lot codes and other company-specific information on its products’ primary packaging and cases. To accomplish these tasks, Ultra Dairy uses small character continuous ink jet printers, laser coders, large character continuous ink jet printers and print-and-apply labelers from Videojet Technologies Inc.

In 2004, Byrne Dairy opened a 40,000 square foot ultra pasteurization manufacturing facility called Ultra Dairy to specialize in extended shelf life (ESL) products such as half-and-half, and light and heavy creams. Today, the Ultra Dairy plant can produce aseptic milk and dairy products that do not require refrigeration, expanding the range of products Byrne Dairy can offer its customers and allowing the company to develop solutions with longer shelf lives for restaurants, businesses and household consumers.

Some of the products developed by Ultra Dairy can have shelf lives as long as 170 days. Ultra Dairy produces products for Byrne Dairy, as well as private label products for nationally branded, large retail companies. With the variety of products, shelf lives and brands processed by Ultra Dairy, the company relies on variable data marking and coding equipment to print expiration dates, lot codes and other company-specific information on its products’ primary packaging and cases. To accomplish these tasks, Ultra Dairy uses small character continuous ink jet printers, laser coders, large character continuous ink jet printers and print-and-apply labelers from Videojet Technologies Inc.

Code accuracy, clarity vital to success

Clear, crisp codes are extremely important to Ultra Dairy because the codes are used to meet government and customer requirements for supply chain traceability. In addition, some of Ultra Dairy’s customers require bar codes that are scanned for inventory purposes. Finally, end consumers rely on clear expiration dates to ensure they are purchasing and consuming a fresh product.

“It is critical for us that the codes on every package are clear, legible and reliable,” says Eric Greiner, ESL sales manager for Ultra Dairy. “If our customers receive a case with a bar code they can’t scan or a product with a code they can’t read, they’ll send it back. We have standardized on Videojet printers because the equipment is reliable and produces clear, consistent codes.”

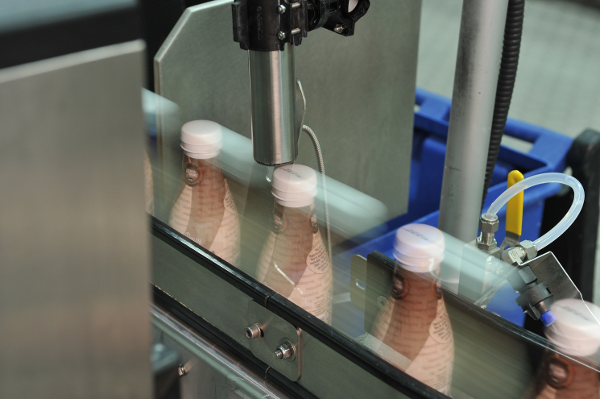

For coding on its bottling line, Ultra Dairy uses the Videojet 1610 small character ink jet printer. On one line, Ultra Dairy codes caps on finished products with the Videojet 1610, and on another line, the Videojet 1610 is set up to code sleeves that are wrapped around bottles.

“It takes very little extra work on our part to keep the Videojet 1610 maintained and running,” says Greiner. “Whether we are running the printer continuously or intermittently, we get great code quality. Plus, the ink and make-up fluids are very easy to change because our line operators just need to change a cartridge, which means we don’t need to call maintenance personnel to help change fluids.”

The fluid cartridges used by the Videojet 1610 also include a microchip that verifies whether the correct fluid has been installed. This is extremely helpful for Ultra Dairy because the company must use different inks for the bottle caps and the sleeves, as the sleeves require an ink with a faster drying time. The microchip ensures the fluids for each substrate cannot be mixed up or incorrectly installed.

“It is critical for us that the codes on every package are clear, legible and reliable,” says Eric Greiner, ESL sales manager for Ultra Dairy. “If our customers receive a case with a bar code they can’t scan or a product with a code they can’t read, they’ll send it back. We have standardized on Videojet printers because the equipment is reliable and produces clear, consistent codes.”

For coding on its bottling line, Ultra Dairy uses the Videojet 1610 small character ink jet printer. On one line, Ultra Dairy codes caps on finished products with the Videojet 1610, and on another line, the Videojet 1610 is set up to code sleeves that are wrapped around bottles.

“It takes very little extra work on our part to keep the Videojet 1610 maintained and running,” says Greiner. “Whether we are running the printer continuously or intermittently, we get great code quality. Plus, the ink and make-up fluids are very easy to change because our line operators just need to change a cartridge, which means we don’t need to call maintenance personnel to help change fluids.”

The fluid cartridges used by the Videojet 1610 also include a microchip that verifies whether the correct fluid has been installed. This is extremely helpful for Ultra Dairy because the company must use different inks for the bottle caps and the sleeves, as the sleeves require an ink with a faster drying time. The microchip ensures the fluids for each substrate cannot be mixed up or incorrectly installed.

Print-and-apply label provides professional solution

On one of Ultra Dairy’s bottling lines, after the bottles are coded with the Videojet 1610, filled bottles are placed in a tray, which is then wrapped in clear plastic and sent through a shrink tunnel. Unique customer information - such as UPC codes, expiration dates and production dates - must be placed on these finished case packs. Because the clear plastic is not a flat substrate, Ultra Dairy prints the information on a white 2-inch by 4-inch label and applies it to the case using a Videojet P3400 print-and-apply labeler.

“The label is very easy to read and looks clean and professional on our finished packages,” Greiner says. “Plus, the labeler is very easy to work with and allows us to build the templates we need to put the information that our customers require on the packages.”

Other products are placed directly into cardboard cases, which are coded by 2300 Series large character continuous ink jet printers from Videojet. The cases are coded with identification information and bar codes in much the same way the labels are used on the shrink-wrapped trays. The combination of human-readable information and bar codes enables customers to determine what is packaged in a case and scan the information into warehouse management systems to track shipping and receiving activities.

“The label is very easy to read and looks clean and professional on our finished packages,” Greiner says. “Plus, the labeler is very easy to work with and allows us to build the templates we need to put the information that our customers require on the packages.”

Other products are placed directly into cardboard cases, which are coded by 2300 Series large character continuous ink jet printers from Videojet. The cases are coded with identification information and bar codes in much the same way the labels are used on the shrink-wrapped trays. The combination of human-readable information and bar codes enables customers to determine what is packaged in a case and scan the information into warehouse management systems to track shipping and receiving activities.

Laser code carries information, keeps packaging appearance clean

Some of Ultra Dairy’s bottled products require a code Ultra Dairy uses for tracking purposes. This code enables Ultra Dairy to keep unique information about the bottling process right on the bottle, including information about the fill head, foil head and cap head involved in the bottling process. Since this code is only used by Ultra Dairy and is covered by a sleeve, the company wanted to make sure the code wasn’t visible through the sleeve.

“We use a Videojet 3320 laser coder to put our unique code onto the PET plastic bottles,” says Greiner. “The laser code ensures it is only visible to us because we know where to look for it, and we really like the fact that the laser coder doesn’t require any ink or external source of air - it only needs electricity to run.”

With Videojet’s help, Ultra Dairy was able to integrate the laser coder into its production line so that the coder receives communication from the bottle filler, which provides the coder with the unique information that needs to be included in the code.

“Getting the serial communication set up represented a bit of a challenge for us,” explains Greiner. “Videojet helped us overcome these complications, and now the solution is rock solid and very reliable.”

“We use a Videojet 3320 laser coder to put our unique code onto the PET plastic bottles,” says Greiner. “The laser code ensures it is only visible to us because we know where to look for it, and we really like the fact that the laser coder doesn’t require any ink or external source of air - it only needs electricity to run.”

With Videojet’s help, Ultra Dairy was able to integrate the laser coder into its production line so that the coder receives communication from the bottle filler, which provides the coder with the unique information that needs to be included in the code.

“Getting the serial communication set up represented a bit of a challenge for us,” explains Greiner. “Videojet helped us overcome these complications, and now the solution is rock solid and very reliable.”

Marking and coding technology meets goals for growth

Greiner notes that Ultra Dairy works to use the Videojet printers as much as possible - the longer the facility can keep production lines running and the more products it can code, the more products it is able to produce and ship to its customers. On the bottling lines, the laser coder and the small character ink jet printers can run up to 16 hours per day, five days per week.

“As we continue to grow, we will probably use the printers even more than we already do,” says Greiner. “These printers are reliable and meet our challenges, and we know they can withstand the workload.”

The printers also have enabled Ultra Dairy to expand the variety of information they can code on packages to meet the needs of private label customers. Each printer stores generic templates to allow line operators to access preset formats and coding-space sizes. The operators can then modify these templates to include required information.

As Ultra Dairy advances its processing technology, it also works to expand the shelf life of its ESL products. When a product’s shelf life is updated, operators can quickly change the number of days before expiration, and the printers calculate the date to be coded on the package.

“Our facility relies on technology to advance our products and ensure they are the highest possible quality,” says Greiner. “The Videojet printers fit in with our goals because they can be implemented along with our other technologies, and they help us advance the services we can provide to our customers.”

“As we continue to grow, we will probably use the printers even more than we already do,” says Greiner. “These printers are reliable and meet our challenges, and we know they can withstand the workload.”

The printers also have enabled Ultra Dairy to expand the variety of information they can code on packages to meet the needs of private label customers. Each printer stores generic templates to allow line operators to access preset formats and coding-space sizes. The operators can then modify these templates to include required information.

As Ultra Dairy advances its processing technology, it also works to expand the shelf life of its ESL products. When a product’s shelf life is updated, operators can quickly change the number of days before expiration, and the printers calculate the date to be coded on the package.

“Our facility relies on technology to advance our products and ensure they are the highest possible quality,” says Greiner. “The Videojet printers fit in with our goals because they can be implemented along with our other technologies, and they help us advance the services we can provide to our customers.”

About the Author

Sascha Benke is the director of vertical marketing, food, for Videojet Technologies Inc. He is responsible for market research, customer segmentation and prioritization, commercialization, and product promotion within the food industry. Benke has a degree in engineering from the Engineering School in Wedel, Germany.

Videojet Technologies