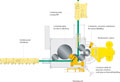

With the DecoBloc from Krones AG, it will be possible to create a monobloc configuration synchronizing a modularized labeler featuring a Sleevematic carousel, a Shrinkmat tunnel and a Linadry unit for predrying the containers. Dairy processors can use this monobloc to run all the labeling processes in common use. All these labeling processes -- cold-glue, pressure-sensitive, hotmelt or shrink-and-stretch sleeves –can be performed quickly with the DecoBloc.

The docking stations feature motorized height adjustment, so that irrespective of the floor level, the labeling stations can be swiftly prepared for a product change-over at the touch of a button. Different machine sizes offer outputs of up to 72,000 containers an hour. Servomotors are used to ensure maximally accurate dress positioning. For sleeving applications, there is a choice between shrink-sleeve labels with a downstream Shrinkmat tunnel or stretch-sleeve labeling. There is also an option for camera-based alignment of the containers on an embossed marking or a container contour, thus ensuring that the labels or sleeves are optimally positioned in relation to the bottle.

Krones

011 +49 9401 70-2222

www.krones.com