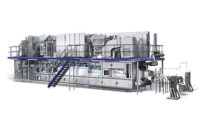

The new generation of Tetra Therm Aseptic Drink pasteurizers enables beverage producers to cut water consumption by up to 80%, energy by up to 30% and product losses by up to 30%, compared to other solutions on the market.

The new generation of Tetra Therm Aseptic Drink pasteurizers enables beverage producers to cut water consumption by up to 80%, energy by up to 30% and product losses by up to 30%, compared to other solutions on the market. This gives higher operational efficiency and lower environmental impact.

Thanks to the introduction of an advanced automation system, the new generation units secure unsurpassed operational efficiency and life-cycle performance.

“With the Tetra Therm Aseptic Drink unit, we want to enable our customers to achieve worry-free operation,” says Sam Strömerstén, president of Tetra Pak Processing Systems. “Each unit can be customized to meet specific customer demands. Each unit is hygienically designed for easy and thorough cleaning. Each unit is pre-tested before shipping. And self-diagnostics assure optimal performance at all times.”

In addition to self-diagnostics, the new generation pasteurizers – which are suitable for juices and nectars, still drinks, tea drinks and enhanced water, including new “wellness” drinks with high value-added sensitive ingredients – include a range of other advanced automation features. For example, the units will automatically identify deviations in process parameters, enabling immediate operator action to maintain optimized operation. And they will provide automatic notification of every maintenance requirement – helping all but eliminate costly, unplanned production stops.

The new pasteurizer is also compatible with the Tetra PlantMaster control system that enables additional intelligence functions such as full traceability, with unit history, batch control and review of all previous actions. These are important aspects that cut the risk of human error and contribute to food safety.

A new balance tank, heat exchangers and deaerators sharply reduce water and energy consumption as well as product loss. Energy consumption is further cut thanks to improved energy recovery through double hot-water circuits.

The new Tetra Therm Aseptic Drink is a good example of an outstanding unit in Tetra Vertenso beverage production solutions; the new name for Tetra Pak’s ability to apply its expertise to develop and deliver customized components and lines that meet the needs of beverage producers and enable them to achieve outstanding operational efficiency.

In addition to Tetra Therm Aseptic Drink pasteurizers, Tetra Vertenso production solutions also comprise proven technology for a vast range of other beverage processing needs, e.g. heat treatment, mixing, blending and many other processes required by cost- and quality-conscious beverage producers.

“With Tetra Vertenso production solutions, Tetra Pak further enhances its capability to offer beverage solutions that are not only tailored to each customer’s products, but also to their production conditions, such as utility costs, environmental legislation and market requirements,“ Strömerstén says.

Tetra Pak

www.tetrapak.com

Related Articles

Events

View AllSubmit An Event-

March 10, 2011 Food Plant of the Future: Renovation Mythbusters

×

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest dairy industry trends.

SUBSCRIBE TODAYCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing