Quantitative synergy can be defined as increased potency of a blend of sweeteners compared to that achieved by individual sweeteners. Qualitative synergy means that the taste profile of a blend matches sugar more closely than that achieved by a single sweetener.

Photo Courtesy of Sunett

Photo Courtesy of Sunett

This story appeared previously inPrepared Foodsmagazine.

The term “synergy” describes a state where the combination of individual parts becomes more advantageous than each of the parts considered separately. This article delves into sweetener synergies and describes why certain sweetener combinations deliver a taste or functionality impact beyond that which is achieved through the use of a single sweetener. Sweeteners are blended not only for flavor adjustment or functionality, but also for economic or dietary considerations. Much of the blending can be attributed to the rising incidences of obesity and diabetes, which has product developers who work in all facets of the food and beverage industry searching for the optimal sugar replacer. Yet, obstacles arise when formulators are faced with such a challenge, as sugar has functional properties beyond its ability to sweeten. For instance, formulators must also consider issues related to texture and flavor balance, as well as how they might replace the bulk that has been removed from the formula.

It is the complex nature of the formulation that dictates the choice of sweetener, regardless of the reason for blending multiple ingredients. Substituting one sweetener for another simply is not practical in the vast majority of cases, which is why it is important to have some knowledge of an individual sweetener’s contribution before focusing on the potential merits of a mixture.

The category of sweeteners is vast and continues to expand as new ingredients are discovered or approved for use an an ingredient additive. Additionally, these products are being used in an increased array of products.

Sweeteners 101

Individual sweetener characteristics are as numerous as the types of sweeteners available for use. Sucrose is just one type of carbohydrate-derived sweetener. Starch-based sweeteners or dextrose-based types include maltodextrin, corn syrup and dextrose. High-fructose corn syrup (HFCS) is derived from a dextrose syrup with a dextrose equivalence (DE) of 95 or greater (DE measures the extent of starch hydrolysis). As the dextrose hydrolysate reacts with glucose isomerase, the glucose is partially converted to fructose. HFCS 42% contains 42% fructose, 53% glucose and 5% more complex sugars. HFCS 55% and 90% are also available.Polyols, or sugar alcohols, are derived from carbohydrates whose reducing sugar has been reduced to a hydroxyl group (an alcohol group). Polyols are versatile ingredients, many of which can be used at levels comparable to sugar. Certain polyols are highly hygroscopic, which enables them to function as humectants. Polyols have reduced caloric levels, reduced insulin response and are non-cariogenic. Xylitol, mannitol and sorbitol have a high negative heat of solution and, therefore, deliver a cooling effect. Polyols do not have a reactive carbonyl group and thus do not contribute to Maillard browning.

High-intensity sweeteners (HIS) are used at very low concentrations due to their sweetening power. The category of HIS includes saccharin, acesulfame-K, aspartame, neotame, cyclamates, sucralose and alitame. Properties and stability of each sweetener vary according to formulation, process and storage conditions.

Many other sweeteners exist, such as fructose-based ingredients, honey and molasses. Additionally, formulators find use for these ingredients beyond what is listed here.

Product Bundling

Sweetener combinations may be formulated based on knowledge of individual sweetener components, yet sweetener-to-sweetener interaction is not necessarily predictable based on individual performance. Nevertheless, formulators must consider a number of factors when choosing a sweetener blend, including approval status, required processing and storage stability, cost, product characteristics such as acidity and flavor, and image or consumer perception, notes Katrin Sälzer, technical marketing manager for an ingredient supplier with expertise in the HIS market.Acquired knowledge of sweetener interactions gives formulators an excellent basis for identifying the optimal blend for a product, says Sälzer. For example, when used on its own, aspartame delivers a long-lasting sweetness and lingering sweet aftertaste. Sucralose has even more pronounced characteristics. However, a mixture of acesulfame-K and aspartame offers a very sugar-like sweetness profile in an orange-flavored soft drink, depending on the use/blend ratio. A blend of acesulfame-K and sucralose is preferable in hot beverages such as tea or coffee, because it offers better sweetness stability at a neutral pH value and hot temperature compared to aspartame when used on its own.

Sweetener combinations often impact the flavor profile of a substrate. “As our flavor/sweetener interaction studies have shown, certain sweetener combinations may highlight some flavors or special flavor notes,” explains Sälzer. “For example, combinations of acesulfame-K and aspartame (30:70) support the fruitiness of strawberry very well, while in orange flavor, the three-way blends of acesulfame-K/aspartame/sucralose or acesulfame-K/aspartame/cyclamate support the fruitiness best.”

A chart of the taste intensity of stevioside and a stevioside/erythritol blend-both possess sweetness-in water at 10% SEV (sucrose equivalence value) shows that erythritol increases the body mouthfeel and decreases the astringent, irritant and licorice characteristics.

Sweeteners are frequently blended to achieve multiple functional properties. For instance, combinations of polyols and HIS in chewing gum achieve functional attributes associated with product positioning such as no-sugar or reduced-sugar, long-lasting flavor and enhanced fruity or cool mint flavor, notes Beth Warren, director of marketing for a leading food ingredient distributor.

Most studies have shown that combinations of HIS exhibit superior flavor properties than any one HIS used on its own, adds Warren. Nutritive sweeteners are blended with one another for economic, flavor and functional reasons, as are nutritive and non-nutritive sweeteners. For instance, HFCS or sucrose is used with aspartame and acesulfame-K in reduced-calorie beverages. Aspartame and fructose improve the flavor impact of the fruit profile in products such as yogurt.

Sweeteners can be blended to support marketing claims. For example, polyols and HIS can assist chewing gum claims to be no- or reduced-sugar, long-lasting flavor and enhanced fruity or cool mint flavor.

Photo Courtesy of ADM

Photo Courtesy of ADM

How Sweet It Is

Many traditional products are being reformulated without sugar in an effort to bring healthier products to market. “With the dangerously high percentages of Americans living with obesity and diabetes, sweeteners’ ability to mesh with other ingredients plays a vital role in enhancing lifestyles,” says Albert Bustos, marketing manager for an ingredients distributor. “Those affected will have more choices in foods and beverages.”When it comes to formulating a sweet taste, scientists continually strive to meet the ultimate goal-blending ingredients in such a way as to precisely imitate the profile of sugar. “Sugar’s taste is the benchmark flavor of a sweetener, hence the products touting ‘tastes like real sugar,’” says Bustos. “Formulators use sweeteners’ synergistic effects to mimic the taste of sugar. Sweeteners such as maltitol, lactitol, erythritol, maltodextrin and tagatose are just some ingredients used to obtain the benchmark.”

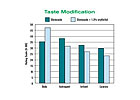

“The applications for sugar and HFCS often rely on the functional benefits for mouthfeel and bulk,” explains Warren. “The challenge is to match the flavor of sugar while maintaining the mouthfeel and texture that the consumer expects. For example, a pudding application for the school lunch program is being repositioned as a healthier product without sugar. Aspartame and acesulfame-K were selected for the sugar-free product because, when combined, the onset and flavor of the two high-intensity sweeteners provide the sweet taste of sugar. Texture modifiers were also selected to optimize the mouthfeel of the pudding. Texture modification is a very complicated, but critical, component of sugar reformulation. Once the flavor has been achieved, the mouthfeel must be considered. Then, the sweetener component may need to be readjusted, as ingredients such as starch have a flavor-masking effect.”

When sugar is removed from a formulation, it often creates a large void that must be filled with a bulking agent. Polydextrose or gum acacia are ingredients that can fill this need. Polydextrose is a low-calorie (1Kcal/g), non-sweet carbohydrate that offers the added benefit of prebiotic enrichment, and gum acacia is a non-sweet hydrocolloid that does not contribute viscosity, but adds soluble fiber for an added fiber claim. Polyol products also may be used to replace the bulk of sugar, notes Warren. For instance, in bakery products, polyols not only contribute bulk but also the humectant properties associated with sugar.

Blending sweeteners to achieve the taste profile of sugar can be one of the more difficult formulation challenges faced by product developers. Individual sweeteners have different temporal profiles causing the sweetness sensation to begin, peak and linger at various rates. More qualitative-type synergies have been achieved through combinations of sweeteners than by single-source use.

Scientists are continually discovering new functional and sensory aspects of sweetener blends. An ingredient supplier with expertise in HIS has paired up with scientists at Duke University on a study of binary and ternary sweetener blends and their effect on time to maximum sweetness intensity. Preliminary reports indicate that the size and complexity of a sweetener’s chemical structure may impact the shape of the time/intensity curve (i.e., blends containing sweeteners with larger molecules such as neotame, alitame and thaumatin had later time to maximum sweetness intensity). “Providing the consumer with a product that is both early in onset and time to maximum sweetness intensity like sucrose, the standard for sweetness, is clearly the task that is essential in sweetener and sweetener blend development,” says Susan Schiffman, lead author of the study from Duke University Medical Center; this sentiment is echoed by food formulators throughout the industry.