Heat exchangers are among the most integral components in any dairy operation. Applying heat is often the most fundamental aspect of dairy processing. The trick is doing it in a way that makes the food safe for distribution and resale, while maintaining flavor and nutrients.

Equipment manufacturers offer three basic types of heat exchangers each of which has some application in dairy processing-plate, tube, and scraped surface heat exchangers.

On the following pages are some examples of the different models that are currently on the market, including a brand new plate heat exchanger that uses industrial steam.

The Tetra Plex units are manufactured by Alfa Laval, the world's leading producers of plate heat exchangers. All Tetra Plex models have very high heat transfer abilities. This means that you can minimize temperature differences between product and service medium. You get gentle treatment of your product while simultaneously minimizing the risk of fouling. The excellent press depth with relatively few contact points yields longer running times and the possibility to use thicker long life gaskets. The plates' patented distribution pattern assures a smooth flow, which also makes CIP easier. The Tetra Plex range includes a wide selection of plates with different geometries and patterns for different applications. Many plates can be supplied in a choice of materials - stainless steel, SMO or titanium. It is simple to disassemble Tetra Plex units for inspection. The glueless gaskets can be replaced quickly and easily on site, with the plates hanging in the frames. The food grade gaskets can be delivered in a range of materials for different applications and temperatures.

The Tetra Plex units are held together by sturdy, pressure graded frames with many smart, hygienic and labor saving features. All frames offer great flexibility for expanding and rebuilding the plate heat exchangers.

Tetra Pak

800/806-9675

Write in 450

tetrapakprocessing.com

The new TS6 features unique geometry, stainless steel plates, special gaskets that tolerate temperatures up to 356º F and a robust frame. It is available in either painted or stainless steel frame versions. These features provide operational performance and economy that is unmatched by either shell and tube or traditional plate heat exchangers. The design and performance of the TS6 adds up to greater lifecycle economy when heating water. Cost savings can be found in both energy and time.

Alfa Laval Inc.

262/947-3706

Write in 451

e-mail: carl.lemke@alfalaval.com

A unique gasket design prevents intermingling of opposing streams by directing any leaking fluid to the outside of the unit. Modular design facilitates re-streaming of heat exchanger to accommodate expanding or changing loads. Controlled turbulence assures the highest rate of heat transfer even at relatively low pressure drop and velocity. When required, higher allowable differential operating pressures permit increased fluid velocities and turbulence. All plate surfaces can be cleaned and sanitized safely and effectively by properly designed in-place recirculation systems. All units easily opened for thorough internal inspection.

Chester-Jensen Co.

800/685-3750

Write in 452

www.chester-jensen.com

Paul Mueller Co.

800/MUELLER (683-5537)

Write in 453

www.muel.com

AGC Engineering

800/715-8820

Write in 454

www.AGCEngineering.com

Alfa Laval

978/463-6326

Write in 455

www.alfalaval.us

Terlet Co., Div. of MPE Group

856/317-9960

Write in 456

www.terlotherm.com

Tetra Pak

800/806-9675

Write in 457

www.tetrapakprocessing.com

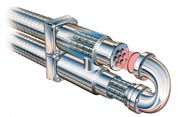

Scherping Systems in-line, single pass heat exchangers are crafted using T304 stainless steel tube sheets, tubes, outer shells and reducing adapters. They are available in standard sizes or manufactured to meet your specific heat transfer capacity and space requiements. The heat exchangers include steam inlet, condensate outlet and vacuum break connections as required. Scherping Systems stocked, standard CIP heat exchangers have concentric and eccentric reducing adapters, reducing solution inlet and outlet ports with required tri-clamp connections. The reducing adapters assure proper drainage of horizontally mounted units. Our standard CIP heat exchangers are capable of increasing solution temperature on average of 40 degrees F per pass at flow rates of up to 170 GPM thus allowing you to reach required CIP temperature quickly. Options include:

- Modulating valves

- Steam traps

- Vacuum breakers

- Tubing hangers and other necessary items for mounting

- T304 stainless steel or T316 stainless steel

800/669-4401

Write in 458

www.scherpingsystems.com